Boxing machine paper box opening method and paper box opening mechanism

A cartoning machine and carton technology, applied in the field of carton opening mechanism, cartoning machine carton opening, can solve the problems of difficult reliability guarantee, low reliability of cartons, limited operating speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below.

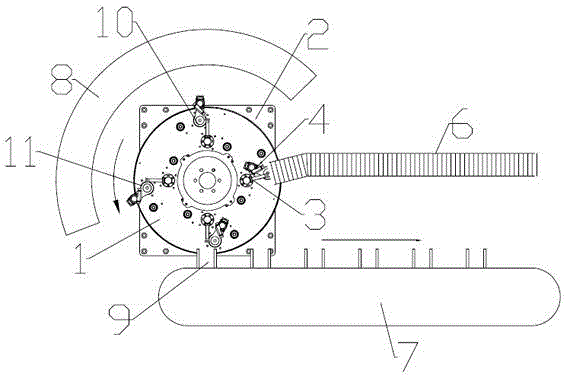

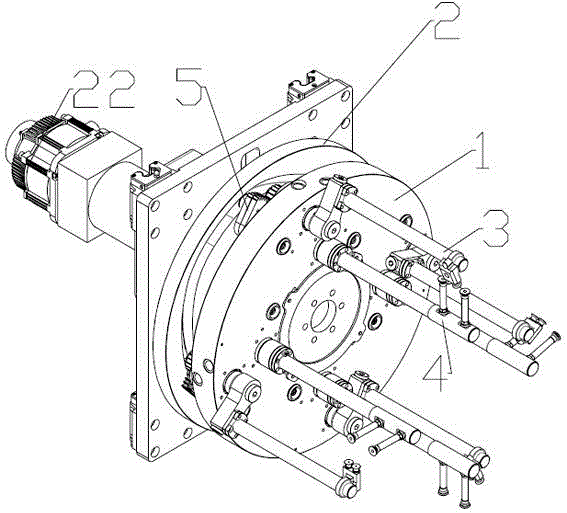

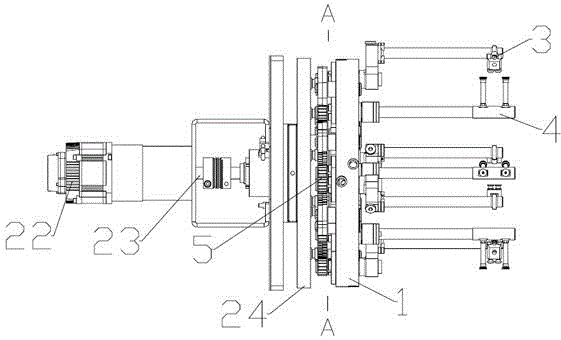

[0052] Such as figure 1 , the method for opening the carton of the cartoning machine of the present invention includes setting the suction box position area, the pre-opening box area 8 and the box-releasing position 9, and the time for suctioning the carton, pre-opening the box and releasing the box is completed by the rotating mechanism Sequentially, a box blank support 6 is provided in the suction box position area for arranging and conveying the carton blanks in a flattened state; a servo motor assembly 2 and a box removal rod assembly 4 with a suction nozzle are provided on the rotating mechanism And the box-opening lever assembly 3 with suction nozzle, the box-taking lever assembly 4 and the box-opening lever assembly 3 are arranged in pairs to complete the suction, pre-opening and box-putting actions of the carton, and the servo motor assembly 2 is used to drive the forming The set take-out le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com