Nanometer polishing solution for titanium oxide film chemical mechanical planarization and application

A titanium oxide thin film, chemical mechanical technology, applied in the field of nano-polishing liquid, to achieve the effect of simple and easy method, no pollution to the environment, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

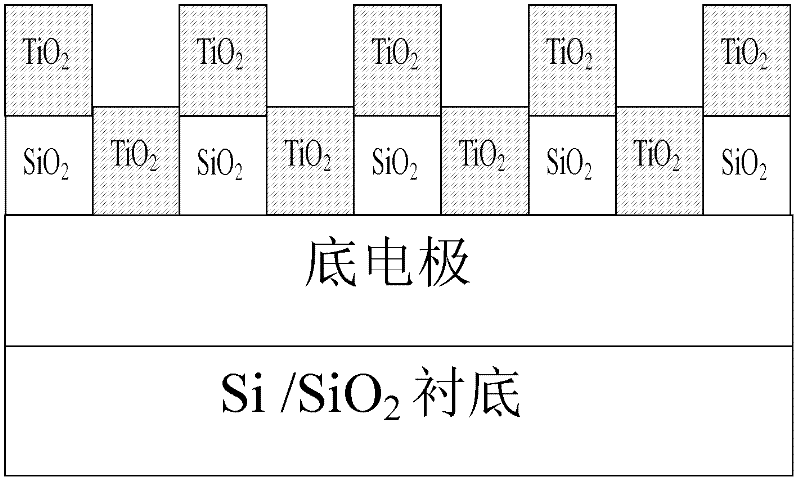

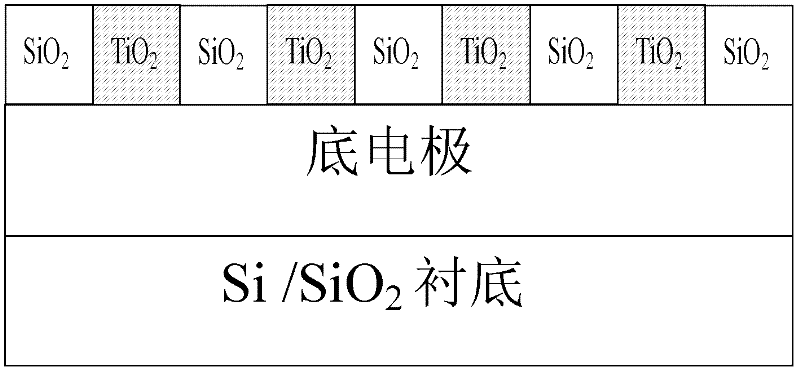

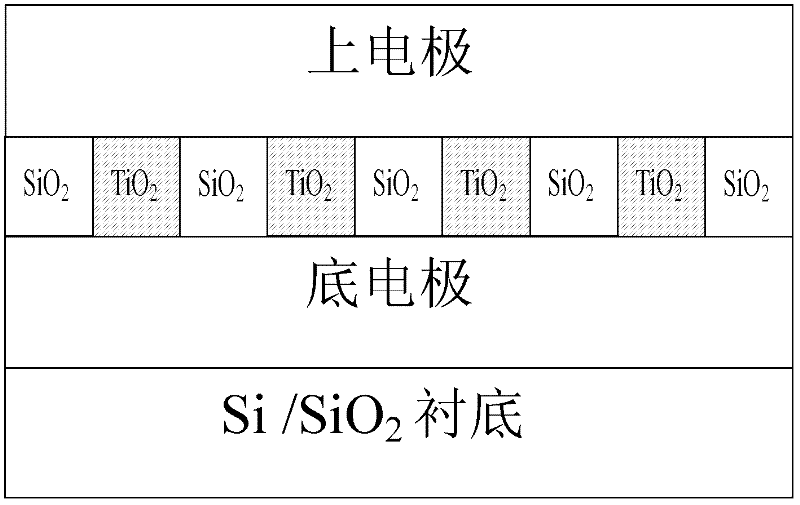

Image

Examples

Embodiment 1

[0030] A nano-polishing liquid for chemical-mechanical planarization of titanium oxide films is composed of nano-abrasives, pH regulators, surfactants, defoamers, bactericides, cleaning aids and solvents.

[0031] Preparation of nano-polishing liquid: the polishing liquid contains 20wt% silica colloid of 10~30nm; 0.2wt% lauryl glycol ether; 50ppm polydimethylsilane; 10ppm isomeric thiazolinone; isopropanol 0.03wt%; KOH and tetramethylammonium hydroxide (volume ratio of 1:1) are the pH regulator, the pH is 8, and the rest is deionized water. When preparing, mix the above raw materials, use a magnetic stirrer to stir evenly, and then directly experiment on the machine.

[0032] Realization of polishing process: 6EC nSpire polishing machine from Strasbaugh in the United States is used, the polishing pad is Rohm&Haas IC1000, the rotational speed of the polishing head is 35rpm, the rotational speed of the polishing disc is 40rpm, the flow rate of the polishing liquid is 100ml / min, ...

Embodiment 2

[0037] A nano-polishing liquid for chemical-mechanical planarization of titanium oxide films is composed of nano-abrasives, pH regulators, surfactants, defoamers, bactericides, cleaning aids and solvents.

[0038] Preparation of nano-polishing liquid: the polishing liquid contains 5wt% of 10~30nm silica colloid, 4wt% of 40nm cerium oxide; 0.1wt% of polyglycol ether, 0.1wt% of dodecyl glycol ether; Methylsilane 50ppm; isomeric thiazolinone 10ppm; isopropanol 0.03wt%; KOH and hydroxylamine (volume ratio 1:3) are pH regulators, pH is 9.01, and the rest is deionized water. When preparing, mix the above raw materials, use a magnetic stirrer to stir evenly, and then directly experiment on the machine.

[0039] The polishing process, polishing sample preparation and polishing effect test are the same as in Example 1.

[0040] Polishing effect: resistive material titanium oxide polishing rate 124nm / min, SiO 2 The polishing rate is 12.3nm / min, the surface roughness RMS (5μm×5μm) befo...

Embodiment 3

[0042] A nano-polishing liquid for chemical-mechanical planarization of titanium oxide films is composed of nano-abrasives, pH regulators, surfactants, defoamers, bactericides, cleaning aids and solvents.

[0043] Preparation of nano-polishing liquid: the polishing liquid contains 10~30nm silica colloid 5wt%, 80nm cerium oxide 2wt%; polyglycol ether 0.3wt%; polydimethylsilane 50ppm; isothiazolinone 10ppm ; Virahol 0.03wt%; H 2 SO 4 And acetic acid (volume ratio 1:3) is the pH regulator, the pH is 6.02, and the rest is deionized water. When preparing, mix the above raw materials, use a magnetic stirrer to stir evenly, and then directly experiment on the machine.

[0044] The polishing process, polishing sample preparation and polishing effect test are the same as in Example 1.

[0045] Polishing effect: resistive material titanium oxide polishing rate 149.8nm / min, SiO 2 The polishing rate is 7nm / min, the surface roughness RMS (5μm×5μm) before polishing is 13.7nm, and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com