Random distributing equipment and method for ceramic forming

A fabric and equipment technology, applied in the equipment field of superfine powder random fabric, can solve the problems of inability to achieve the effect of natural marble, high requirements for material selection, complex template processing, etc., and achieve convenient replacement of pit belts, good effect, and practical equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

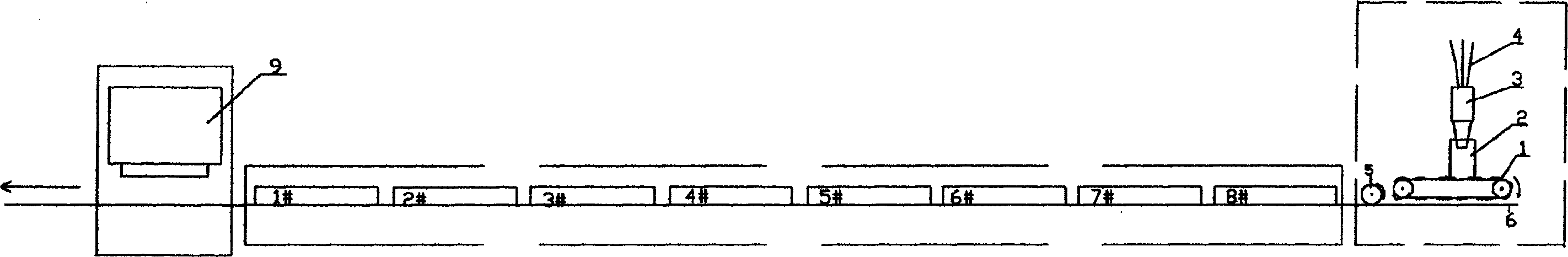

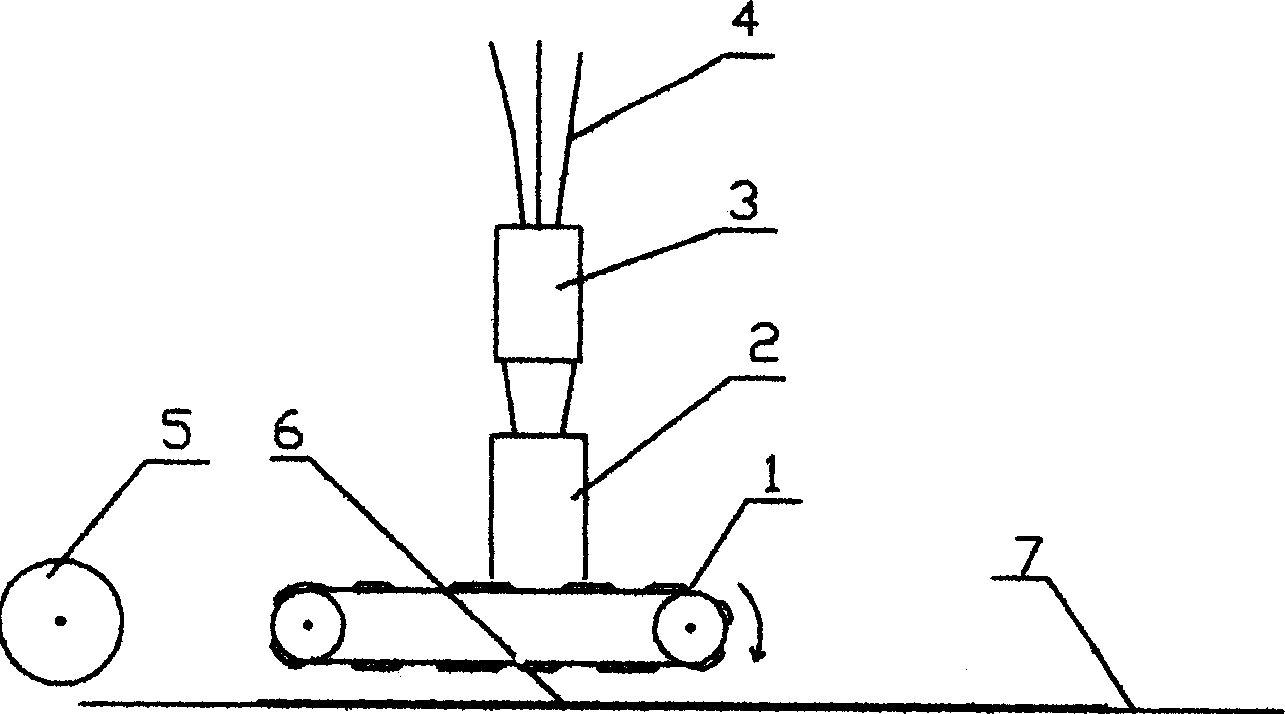

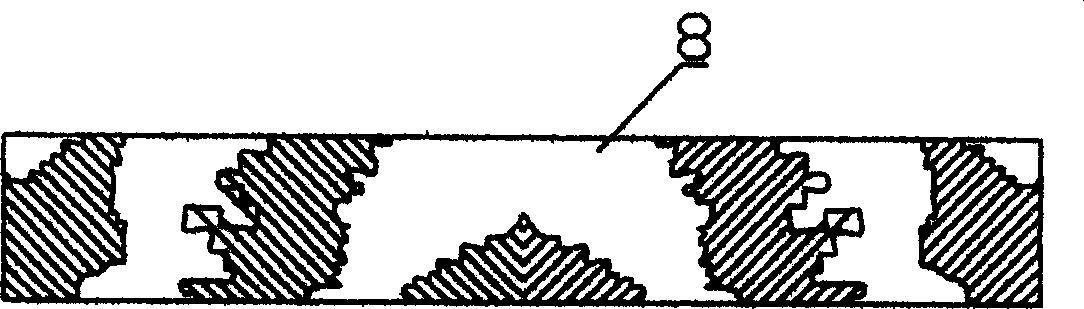

[0025] like Figure 2 to Figure 4 As shown, the technical solution of the present invention is composed of a set of random distribution equipment and a method that cooperates with the distribution system currently on the market. The outside of the machine also includes a pit belt 8 and a fixed-thickness compaction roller 5 . The upper part of the mixing barrel 3 is provided with a blanking pipe 4, the lower part is connected to the hopper 2, the pit belt 1 is arranged on the leather pad 6 at the lower part of the micropowder hopper 2, and the thickness-fixing compaction roller 5 is arranged on the working platform on the side of the pit belt 1 upper. The pit belt 1 is designed into a certain pattern, such as Figure 4 , The pit belt is provided with a pit belt depression 8, the pit depth is 8-20mm, and the inclination of the inner wall of the pit is 30°-80° to reduce dead angles and facilitate smooth blanking.

[0026] The random distribution method is to fill the pit belt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com