Rotating cylinder type random material output mixing device

A technology for mixing devices and raw materials, applied in mixers, fluid mixers, dissolution and other directions, can solve the problems of use, inability to provide pigments, trouble, etc., and achieve the effect of uniform color and automatic color mixing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

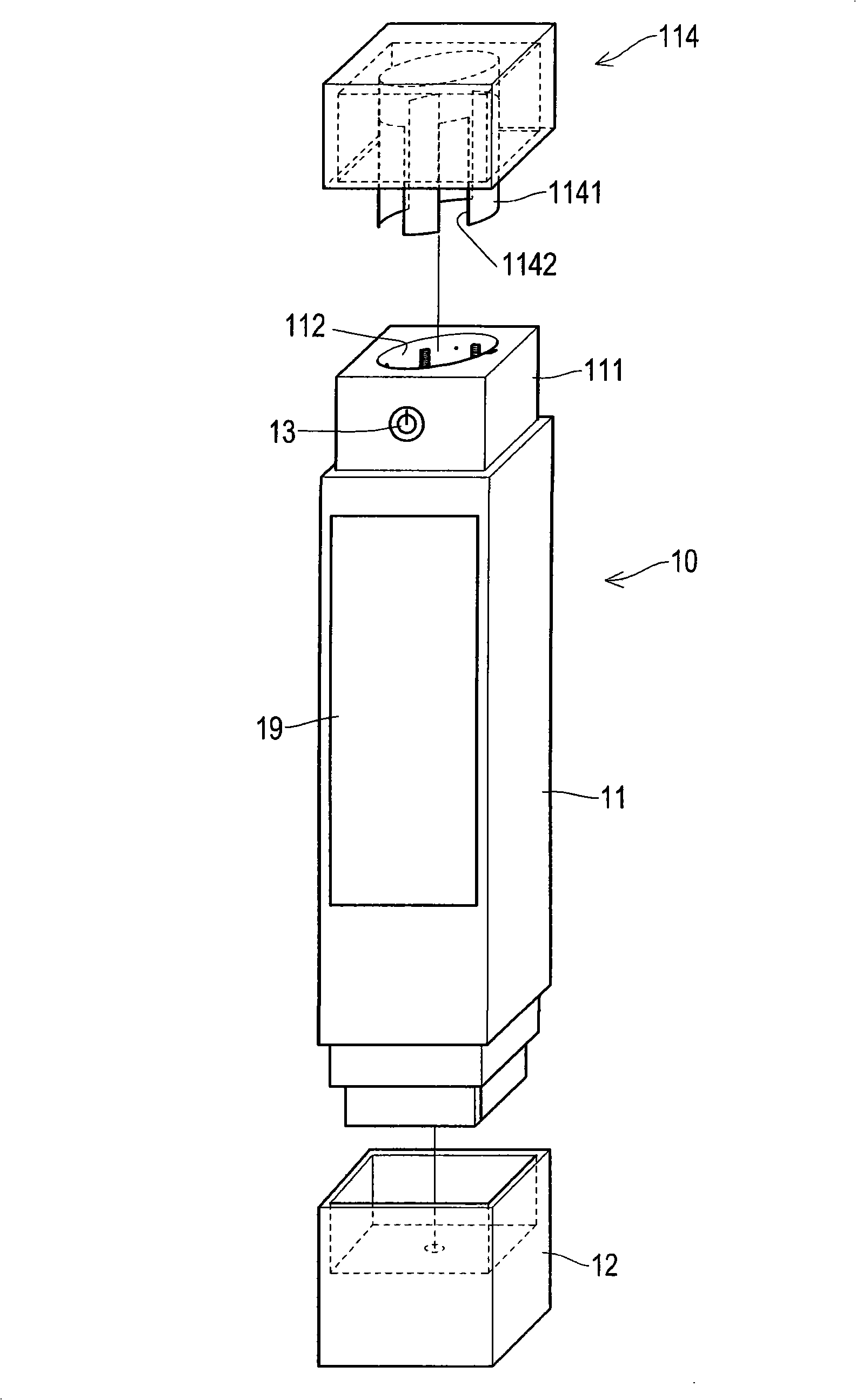

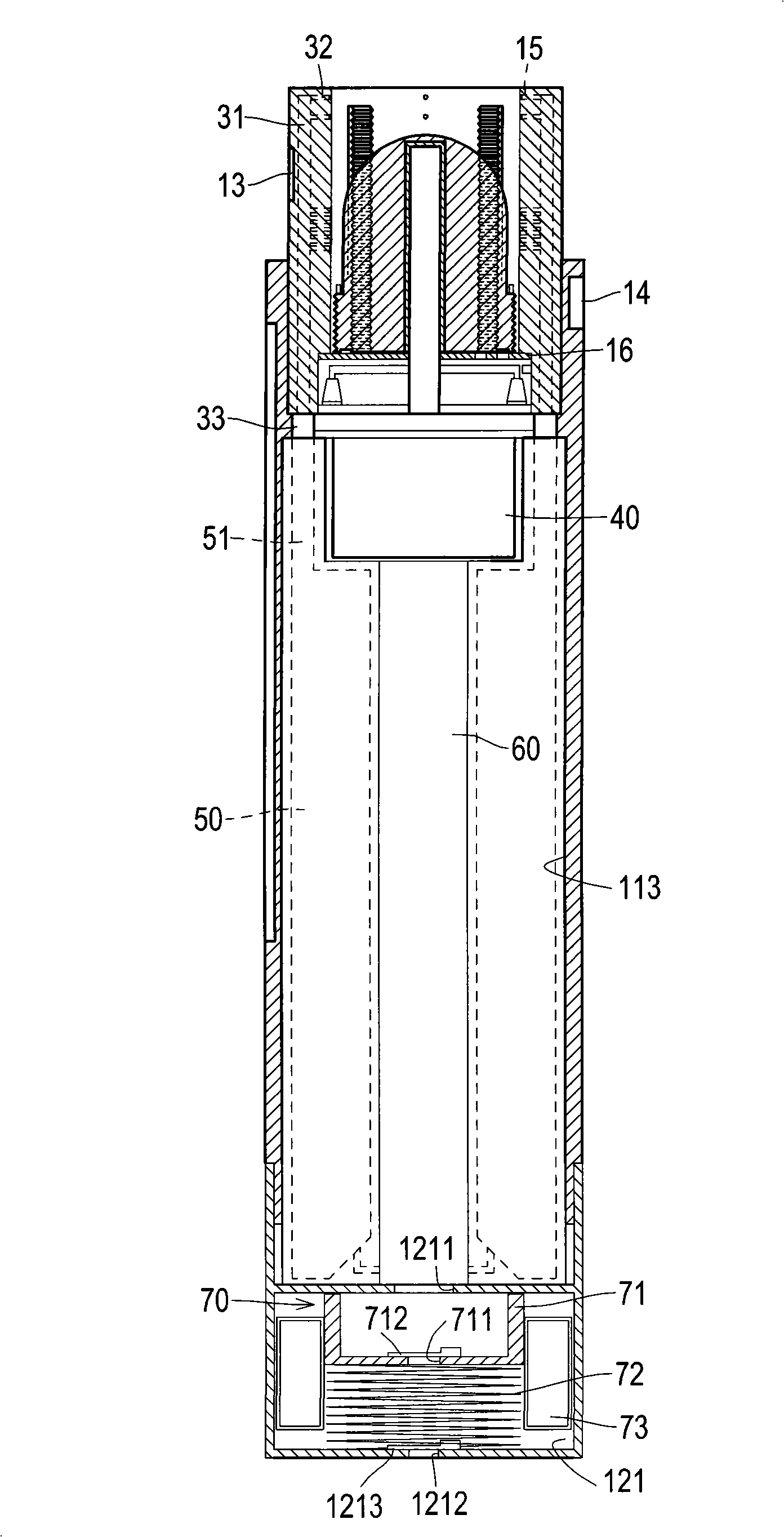

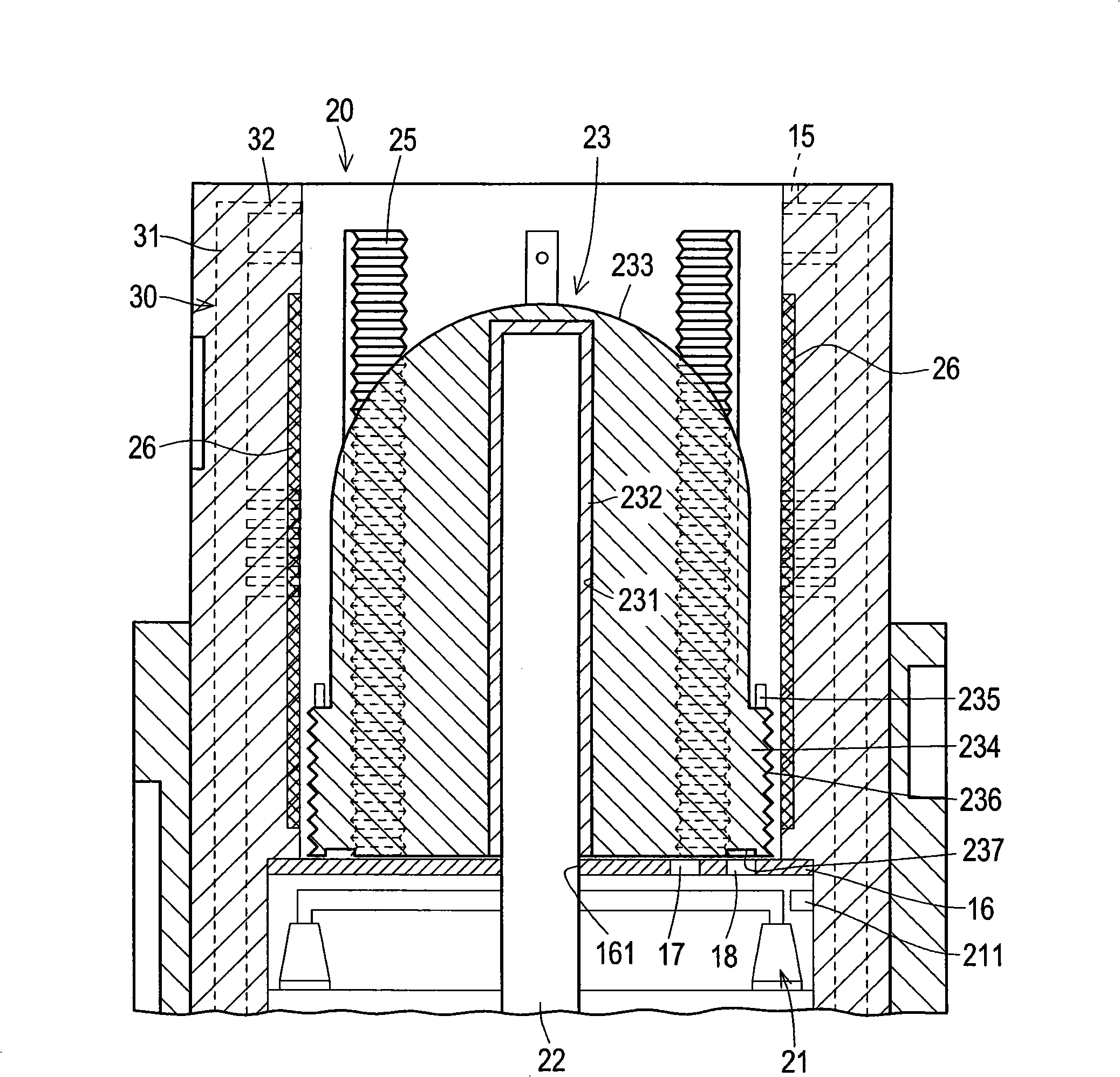

[0032] The present invention is a rotary cylinder type on-demand raw material output mixing device, please refer to Figure 1 to Figure 7 The first preferred embodiment, which is to include:

[0033] A housing construction 10, see Figure 1 to Figure 3 , the shell structure 10 is provided with a housing 11, the housing 11 is a square straight rod body and forms a head 111 at the front end, and a cylindrical mixing chamber 112 is formed at one end of the head 111, and the mixing chamber 112 is formed in the housing 11 A battery raw material chamber 113 is formed behind the chamber 112. The battery raw material chamber 113 has a larger diameter and has an opening at the rear. A rear cover 12 is embedded in the rear end of the casing 11, and the rear cover 12 seals the battery raw material. The rear end of the chamber 113 forms an air compression chamber 121 at the rear end in the rear cover 12, and is respectively provided with an air outlet 1211 and an air inlet 1212 in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com