Microparticle lens array holographic printing

A printing and particle technology, applied in screen printing, optics, instruments, etc., can solve the problems of limited pressing mode production, unable to obtain true color output, unable to achieve holographic three-dimensional printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

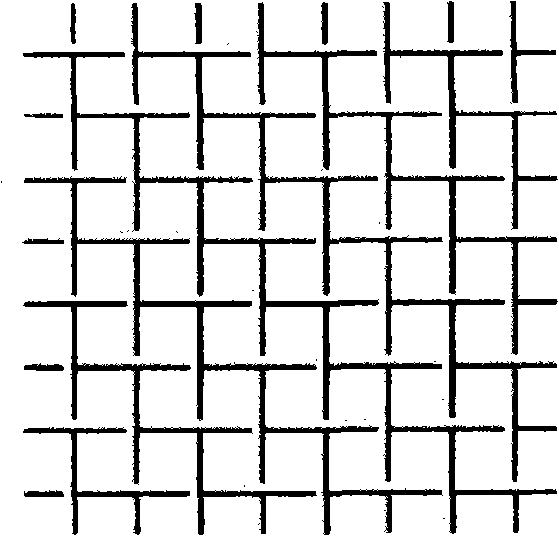

[0031] figure 1 It shows a mesh structure used in the present invention, which is basically similar to the silk mesh structure used in the prior art, and can be printed with microbead arrays of different structures according to its woven shape. For other structures, please refer to the following description of the template structure of different materials, which will not be repeated here.

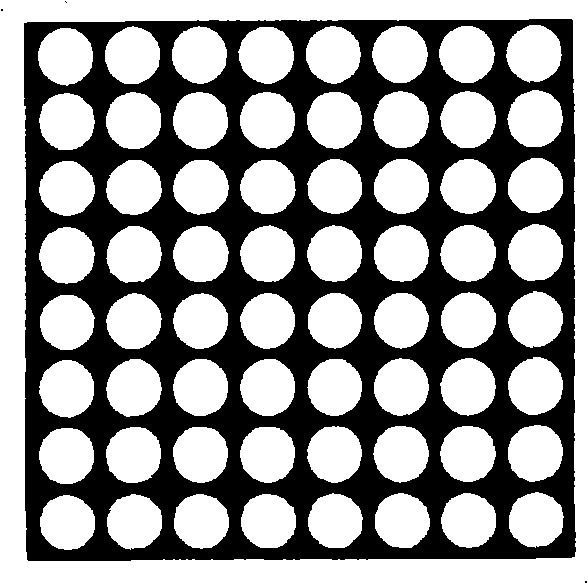

[0032] figure 2 Shown is another stencil structure used in the present invention. It uses any material that can be processed into a stencil, such as stainless steel plate and other metal plates, and uses common methods and methods such as corrosion, laser engraving, and stamping on the steel plate. The square, round or other shapes formed on the surface are suitable for the stencil for microbead array production, as shown in this figure, which is suitable for microbead matrix printing.

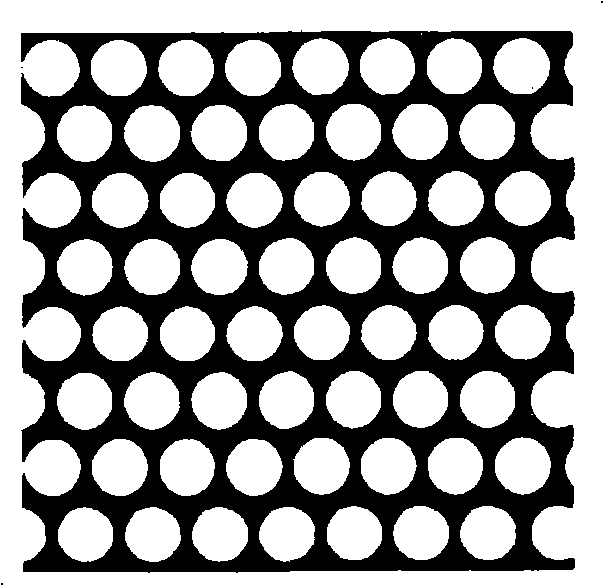

[0033] image 3 Shown here is the use of any material that can be processed into a template, such as st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com