Organic solar cell device and preparation method thereof

A solar cell and organic technology, which is applied in the fields of electric solid state devices, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of cumbersome and complicated preparation process, poor matching of decoration layer materials, and reduced device working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of the conjugated polymer adopted in the following examples is as follows:

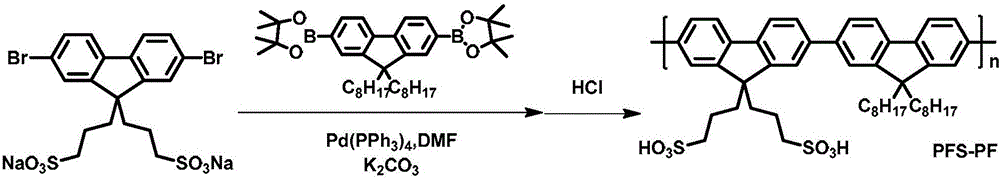

[0065] (1) Preparation of conjugated polymer PFS-PF:

[0066] Prepare the conjugated polymer PFS-PF according to the following steps, the synthetic route is as follows figure 1 Shown:

[0067] Add 0.6122g 9,9'-sodium propylsulfonate-2,7-dibromofluorene, 0.6425g 9,9'-dioctyl-2,7-pinacol borate fluorene, 25mgPd into a 50mL two-necked bottle (PPh 3 ) 4 , 2mLNa 2 CO 3 (2M) and 20 mL of DMF. Under argon atmosphere, react at 95°C for 48 hours. After the reaction, the system was poured into 1M hydrochloric acid and stirred for half an hour, and a large amount of solids were precipitated. The obtained solid was dissolved in DMF and settled with ether, and this was repeated three times. Finally, 0.35 g of light yellow flocculent solid was obtained, with a yield of 44%. Theoretical calculation value [C 48 h 62 o 6 S 2 ]: C, 72.14; H, 7.82. Found: C, 66.19; H, 7.74.

...

Embodiment 1

[0082] Embodiment 1, preparation organic solar cell device (comparative example)

[0083] PBDT-TS1 and PCBM were blended and dissolved in dichlorobenzene at a weight ratio of 1:1.5 to prepare a 15 g / L blended active layer solution. Fabrication of polymer photovoltaic devices on transparent ITO substrates. The commonly used anode modification layer PEDOT:PSS was spin-coated on the ITO surface for modification, and the thickness of the PEDOT:PSS layer was measured to be 30nm using a DektakXT film thickness meter. Next, the blended active layer solution was spin-coated into a thin layer with a thickness of 100 nm. Next, a 0.5 mg / mL PFN methanol solution was spin-coated at a rotational speed of 3000 rpm to obtain a cathode interface modification layer. Finally, at about 10 -4 A thin layer of 80nm aluminum is vapor-deposited under the pressure of Pa to obtain a polymer solar cell device with a conventional structure, and its structural schematic diagram is as follows Figure 8 ...

Embodiment 2

[0085] Embodiment 2, preparation organic solar cell device (PFS-PF is used as cathode interface modification layer)

[0086] PBDT-TS1 and PCBM were blended and dissolved in dichlorobenzene at a weight ratio of 1:1.5 to prepare a 15 g / L blended active layer solution. Fabrication of polymer photovoltaic devices on transparent ITO substrates. The commonly used anode modification layer PEDOT:PSS was spin-coated on the ITO surface for modification, and the thickness of the PEDOT:PSS layer was measured to be 30nm using a DektakXT film thickness meter. Next, the blended active layer solution was spin-coated into a thin layer with a thickness of 100 nm. Next, a 0.5 mg / mL PFS-PF methanol solution was spin-coated at a rotational speed of 3000 rpm to obtain a cathode interface modification layer with a thickness of 2 nm. Finally, at about 10 -4 A thin layer of 80nm aluminum is vapor-deposited under the pressure of Pa to obtain a polymer solar cell device in which PFS-PF is used as a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com