Ceramic coating sagger for manufacturing lithium ion anode active material and manufacturing method thereof

The technology of a positive electrode active material and manufacturing method is applied in the direction of furnace components, furnaces, lighting and heating equipment, etc., which can solve the problems of not being able to be used as a product, the performance degradation of lithium ion positive electrode active materials, etc., and achieve the effect of excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

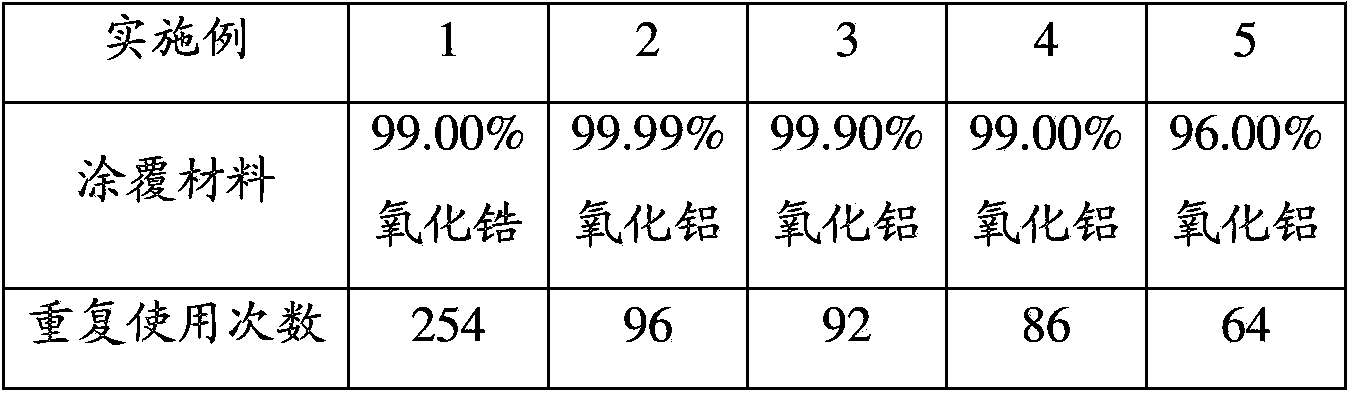

[0036] Lithium-containing composite oxides as lithium ion positive electrode active material materials use lithium nickel cobalt manganese system (collectively referred to as ternary system) as the starting material, and add 5 kg of the starting material to each lithium ion positive electrode active material. The raw materials were heated in a roller kiln at a maximum temperature of 950°C for 9 hours, and then the temperature in the furnace was lowered by introducing air, and the burnt product of the sagger and the lithium-ion positive electrode active material material was forcibly cooled. This manufacturing process was repeatedly implemented until it was determined that the saggar was unusable, and the lifetime of the saggar was evaluated. The results are shown in Table 1. In addition, as a comparative example, the same test was performed using a sagger main body made of mullite or mullite-cordierite without the spraying process, and the results are shown in Table 2. In add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com