An Alternate Feeding Type Screen Welding Equipment

A welding equipment and material feeding technology, which is applied in the field of alternate feeding type mesh welding equipment, can solve the problems of affecting the operation efficiency of the equipment, unsatisfactory welding effect, and poor quality of the metal mesh, so as to improve the operation efficiency of the equipment, save the standby time, and strengthen the The effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

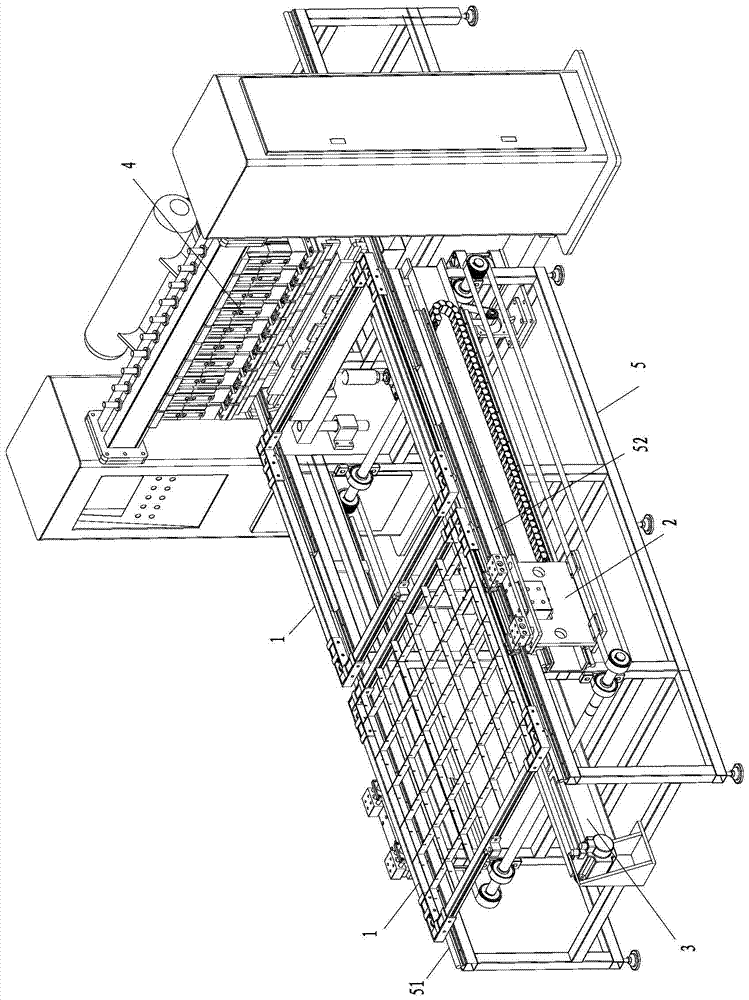

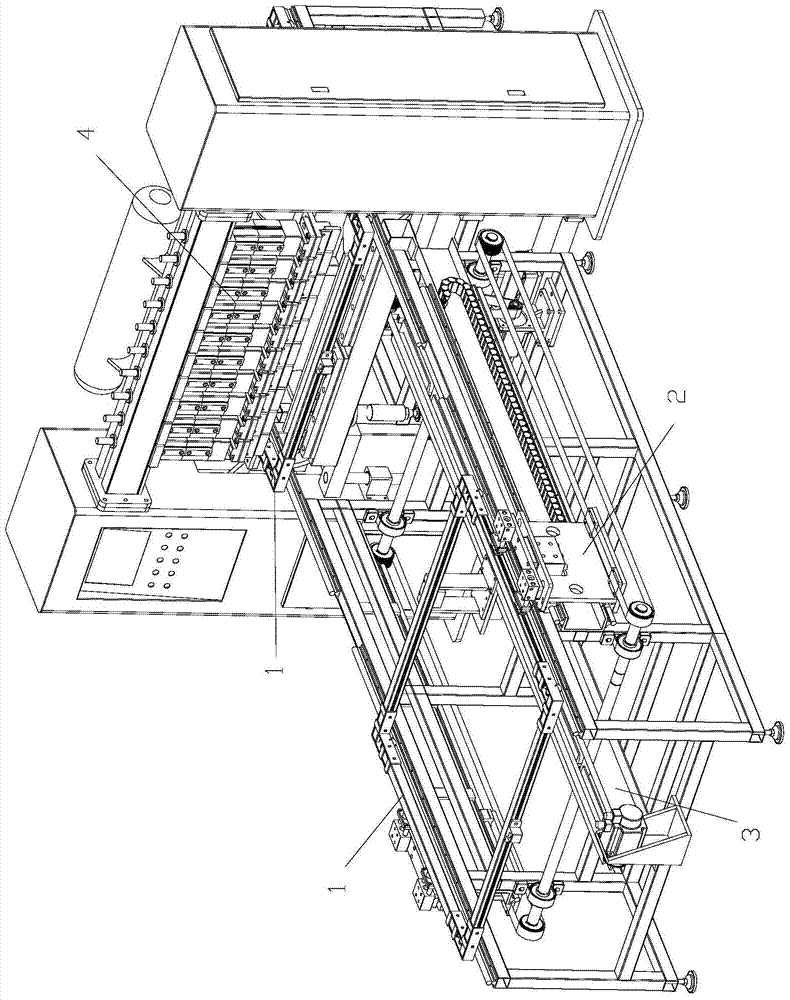

[0037] In this embodiment, the alternate feeding type screen welding equipment is described by taking two discharge racks as an example; its structure is as follows Figure 1 to Figure 7shown. The net discharge welding equipment includes a frame 5, two discharge racks 1 for arranging metal wires, a lifting device 2 for moving the discharge rack 1 up and down, a moving device 3 for driving the discharge rack 1 to move back and forth, And an electric welding device 4 for welding metal wires to form a metal mesh. The net-discharging and welding equipment in this embodiment can realize the discharge, movement and electric welding of the metal wires, so that the metal wires can be welded to form a metal mesh.

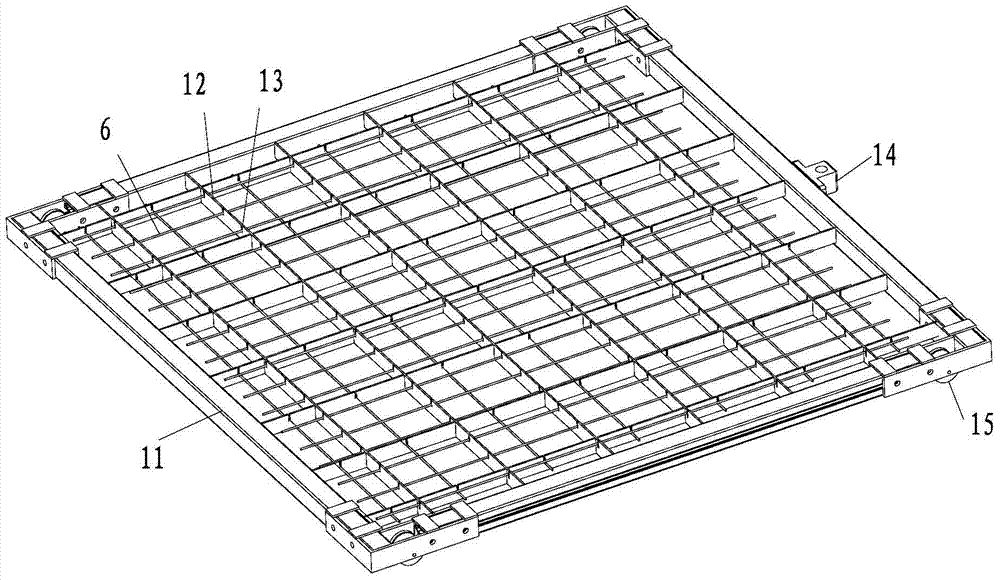

[0038] The discharge frame 1 comprises a frame 11 that is movably arranged on the frame 5, and a grid 12 base that is connected with the frame 11; the base of the grid 12 is provided with some positioning openings 13 that are upwardly opened and are used for fixing wires, s...

Embodiment 2

[0050] Alternate feeding type screen welding equipment in this embodiment includes a frame, at least two discharge racks for arranging metal wires, a lifting device for moving the discharge rack up and down, and a moving device for driving the discharge rack to move back and forth One, and an electric welding device for welding metal wires to form a metal mesh.

[0051] Each discharge rack is respectively movable on the frame; the lifting device is set on the frame through the mobile device 2 to realize the lifting device moving forward and backward; the mobile device 1 and the electric welding device are respectively arranged on the frame; The lifting device is connected; the remaining one or more discharge racks are connected to the mobile device; the electric welding device is electrically connected to the external power supply.

[0052] When the number of discharge racks is more than three, the connection between the remaining one or more discharge racks and the mobile dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com