Random material washing sieve

A technology for washing materials and sieving bodies, which is applied in the direction of filtering, solid separation, and grids, etc. It can solve the problems of increasing equipment manpower investment and energy consumption, difficulty in controlling the amount of mixing water, and affecting the quality of cement concrete, etc., to achieve good application Prospect and promotional value, increasing water washing function, increasing energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

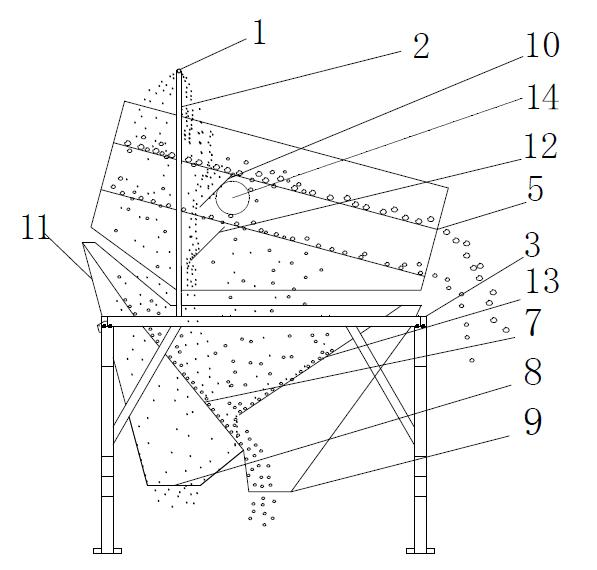

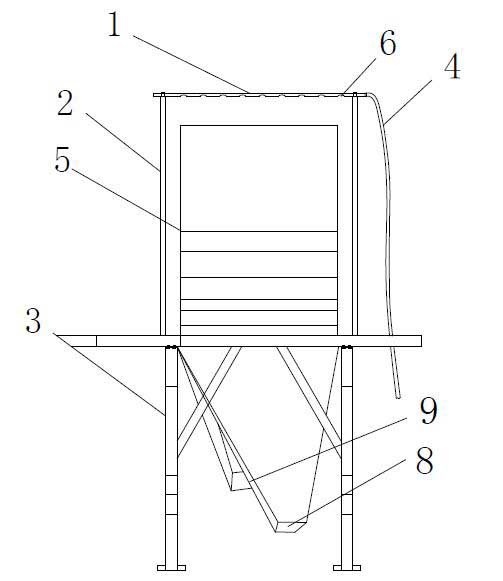

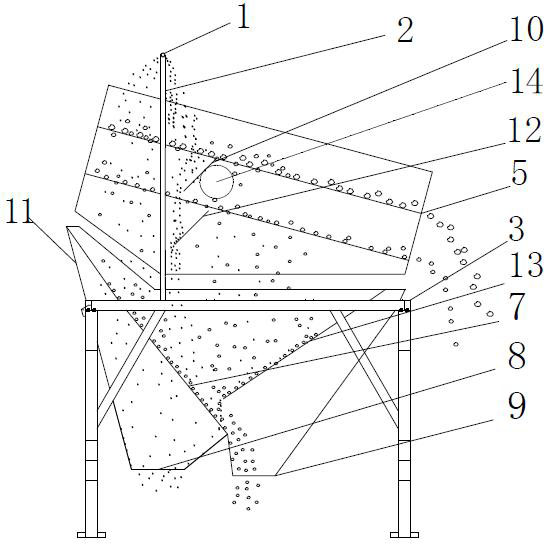

[0013] Depend on Figure 1-2 As can be seen from the shown embodiment, it includes a sieve body 5, a sieve body support 3, a blanking bin 11 and a vibrating shaft 14. In addition, a water spray device is provided above the front of the sieve body 5; Composition, the upper screen is a square mesh, the lower screen is a long hole; the water spray device includes a water spray pipe 1, the water spray pipe 1 is fixedly connected with the screen body support 3 through the column 2, and one end of the water spray pipe 1 It is a blind end, the other end is socketed with the hose 4, and there is a row of water spray holes 6 below it; the screen body 5 also includes a layer of water guide plate 10 and a second layer of water guide plate 12, and the first layer of water guide plate 10 is connected with the screen The vibrating shaft 14 inside the body 5 is fixedly connected, located below the upper screen, the two ends are connected to the screen frame, and the bottom is inclined to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com