Random material mixer and mixing method

A technology of mixer and mixing barrel, which is applied in the direction of chemical instruments and methods, mixing operation control, mixing operation control device, etc., which can solve the problems of dull decoration effect, inability to simulate the overall layout of bricks, lack of aesthetic feeling, etc., and achieve The effect of good economic benefits and application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

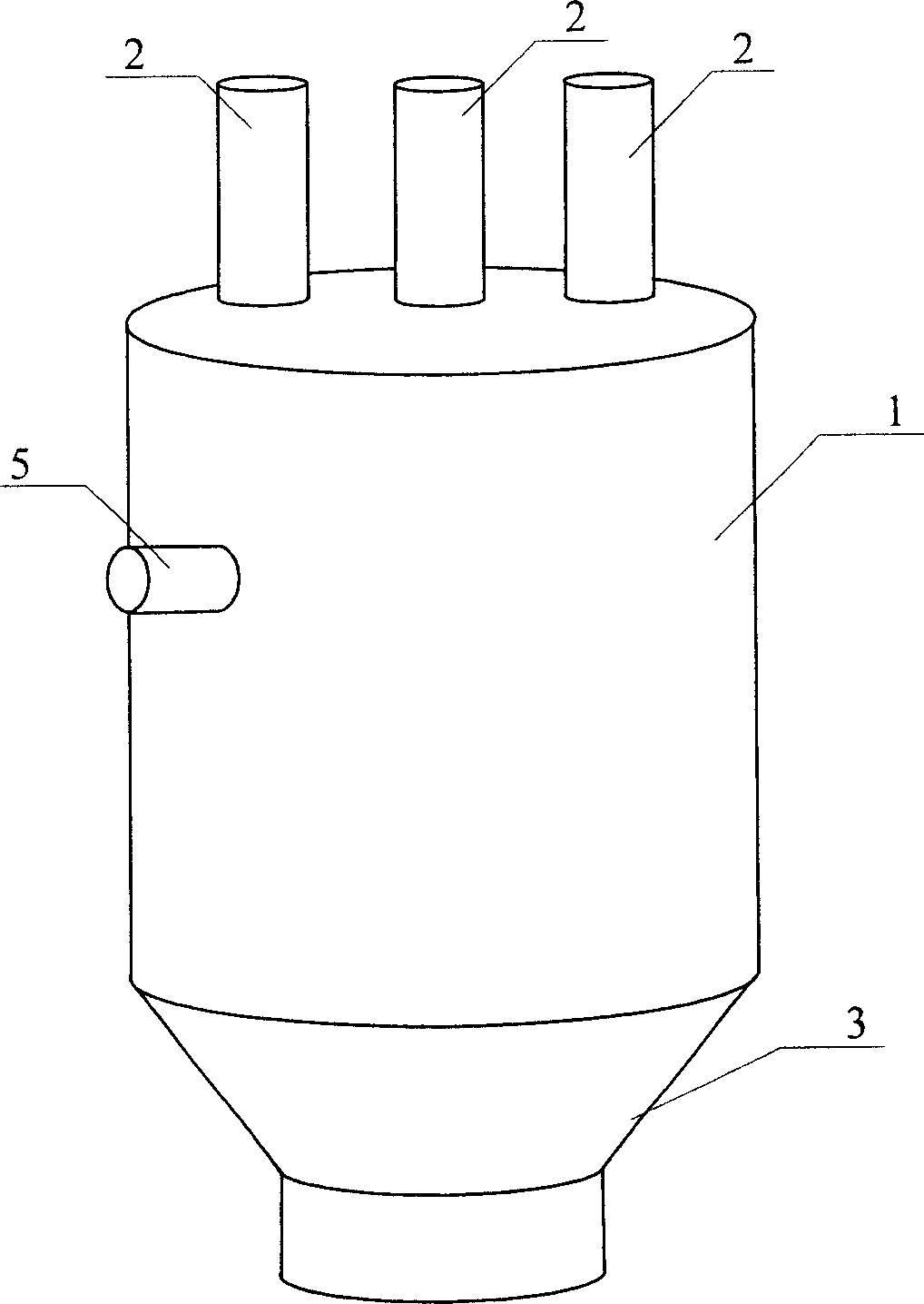

[0021] figure 2 Shown is the schematic diagram of the three-dimensional structure of the first embodiment of the present invention, which includes a cylindrical mixing tube 1, the top of the mixing tube 1 is provided with three feeding openings 2, and a funnel-shaped outlet is connected to the bottom. Material port 3. The wall of the mixing cylinder 1 is provided with an electrically controlled open air nozzle 5 connected to the control signal output end of the electric controller. In production, connect the air inlet of the air nozzle 5 with the outlet of the air compressor, and connect the electric control signal input end of the air nozzle 5 with the control signal output end of the industrial control computer. The granular materials of three different colors are fed into the mixing cylinder 1 through the three feeding openings 2 respectively, and the industrial control computer randomly generates control signals to make the air nozzle 5 open randomly, and the compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com