Transparent, fast-cured and thixotropic dealcoholization one-component silicone rubber

A fast-curing, dealcoholization technology, applied in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problems of unsatisfactory product storage performance, decreased use performance, troublesome production, etc., to improve storage stability, excellent Thixotropy, effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

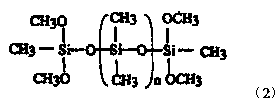

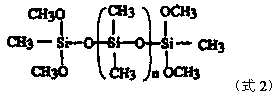

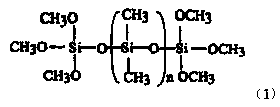

[0049] 40 parts by weight of trimethoxysilane-terminated polydimethylsiloxane (viscosity: 20,000 cps at 25°C), 60 parts by weight of end-methyldimethoxysilane-end polydimethylsiloxane (viscosity: 20,000 cps at 25°C) Parts by weight, 10 parts by weight of fumed white carbon black was put into a double planetary mixer, vacuumized and stirred for 20-30min, and then 6 parts by mass of methyltrimethoxysilane, 2 parts by mass of tetra-tert-butyl titanate, 3-(methyl 1.5 parts by mass of acryloyloxy)propyltriethoxysilane, vacuumize and stir for 20-30 minutes, then discharge and seal for storage.

[0050] The prepared RTV-1 silica gel has good transparency, excellent thixotropy, surface drying time of 7 minutes (temperature 23 ℃ / humidity 55%), 24 hours of curing 5mm, tensile strength of 1.8MPa, fracture productivity of 350%, Shore hardness of 35 , After 12 months of storage, there is no significant difference between extrusion vulcanization and the newly produced silica gel.

Embodiment 2

[0052] 20 parts by weight of trimethoxysilane-terminated polydimethylsiloxane (viscosity: 50,000 cps at 25°C), 80 parts by weight of end-methyldimethoxysilane-end polydimethylsiloxane (viscosity: 80,000 cps at 25°C) Parts by weight, 5 parts by weight of polydimethylsiloxane (viscosity of 1000cps at 25°C), 10 parts by weight of fumed silica, put into a double planetary mixer, vacuumize and stir for 20~30min, then add tetraethyl orthosilicate 5 parts by mass, 4 parts by mass of tetra-tert-butyl titanate, 0.005 parts by mass of dibutyltin dilaurate, 1.5 parts by mass of γ-[(2,3)-epoxypropyl]propyltrimethoxysilane, vacuum stirring After 20-30 minutes, the material is sealed and stored.

[0053] The prepared RTV-1 silica gel has good transparency, excellent thixotropy, surface drying time 2min (temperature 23 ℃ / humidity 55%), 24h curing 7mm, tensile strength 1.6MPa, fracture productivity 470%, Shore hardness 29 , After 16 months of storage, there is no significant difference betwe...

Embodiment 3

[0055] 100 parts by weight of polydimethylsilane (viscosity of 50,000 cps at 25°C) and 5 parts by weight of polydimethylsiloxane (viscosity of 1,000 cps at 25°C) of methyldimethoxysiloxane-terminated polydimethylsiloxane, vapor phase whitening Put 15 parts by weight of carbon black into a double planetary mixer, vacuumize and stir for 20~30min, then add 2 parts by mass of methyl trimethoxy, 4 parts by mass of methyl orthosilicate, 6 parts by mass of tetra-tert-butyl titanate, γ- 1 part by mass of aminopropyltrimethoxysilane, 0.5 part by mass of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, vacuumize and stir for 20 to 30 minutes, then discharge and seal for storage.

[0056] The prepared RTV-1 silica gel has good transparency, excellent thixotropy, surface drying time of 2 minutes (temperature 23 ℃ / humidity 55%), 24 hours of curing 6mm, tensile strength of 2.1MPa, fracture productivity of 410%, Shore hardness of 33 , After 16 months of storage, there is no significant differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com