High anti-crack damping coating

A damping coating and high crack resistance technology, applied in the field of damping coatings, can solve problems such as cracking, and achieve good stone chip resistance and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

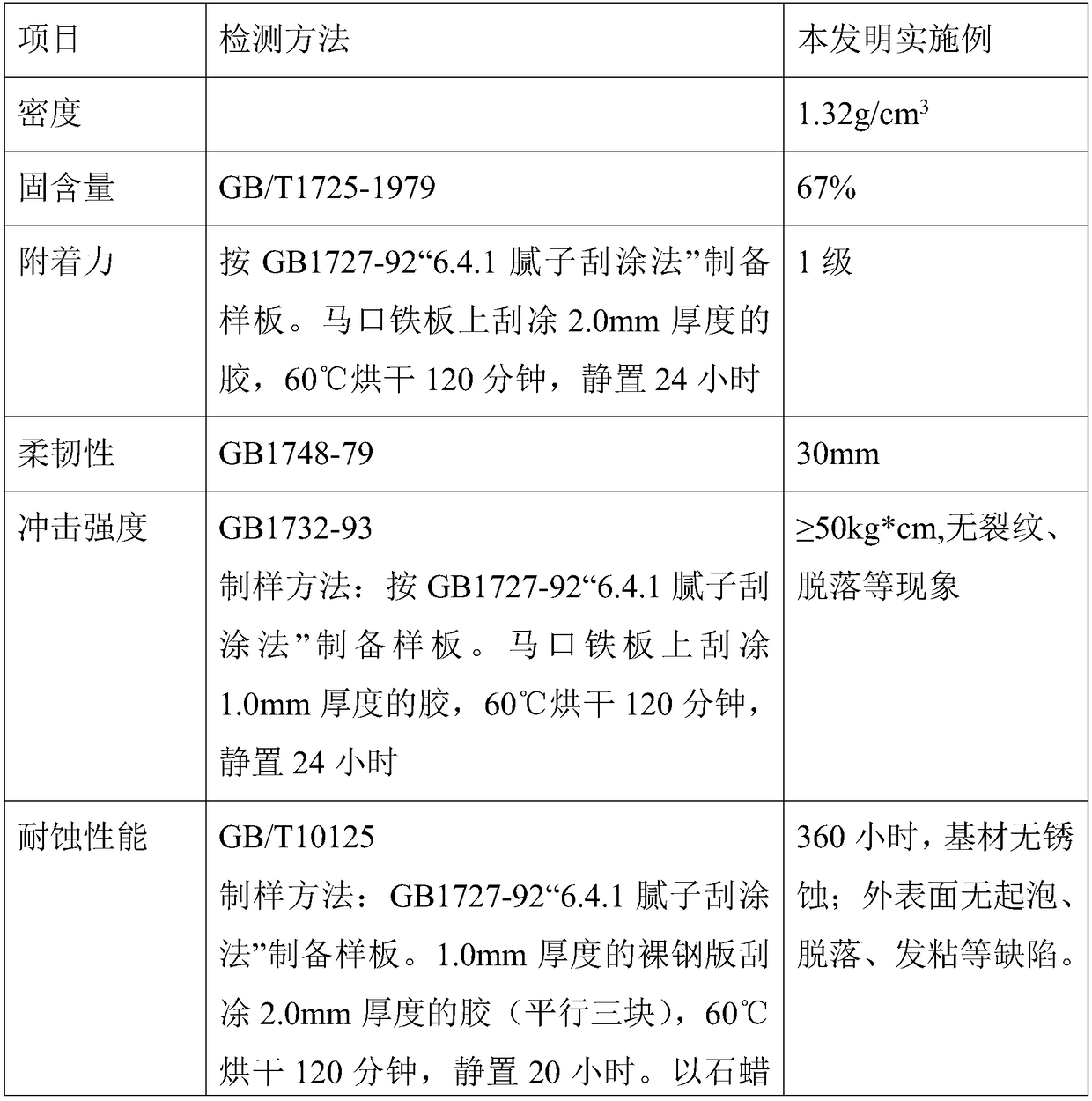

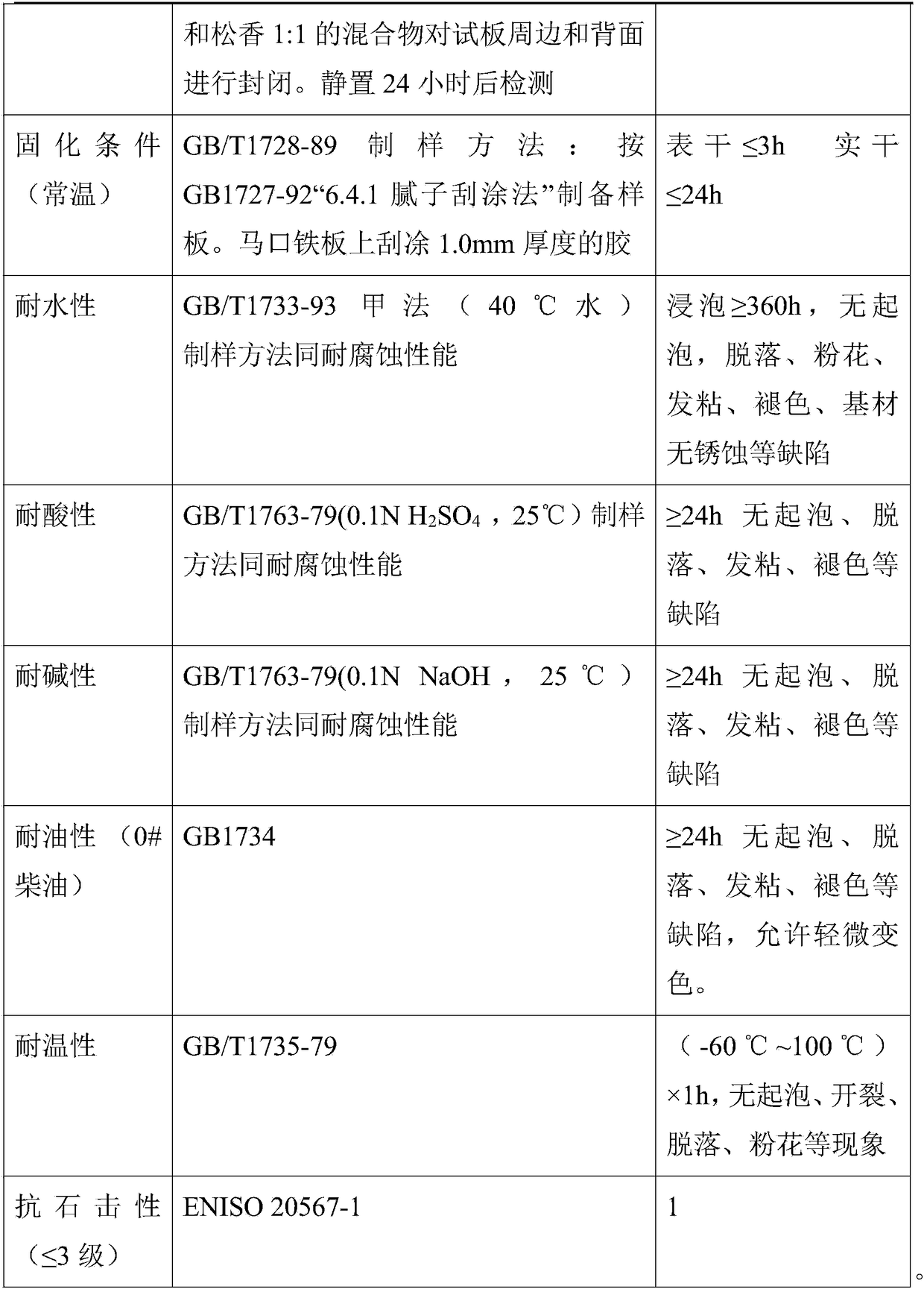

Examples

Embodiment 1

[0035] A high anti-crack damping paint, calculated by weight parts, comprising the following raw materials:

[0036] 300 parts of acrylic waterproof emulsion, 100 parts of antirust emulsion, 50 parts of plasticized acrylic emulsion, 15 parts of alcohol ester twelve, 25 parts of preservative, 5 parts of black paste, 100 parts of magnesium hydroxide, 50 parts of floating beads, 50 parts of talcum powder part and 50 parts of nano-montmorillonite / polyaniline composite powder.

[0037] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0038] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd. Its solid content is 41±1%, pH is 7-7.5, glass transition temperature is 20°C, minimum film-forming temperature is 30°C, and viscosity is less than 20cps , with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good weather resistance and good corro...

Embodiment 2

[0048] A high anti-crack damping paint, calculated by weight parts, comprising the following raw materials:

[0049] 290 parts of acrylic waterproof emulsion, 95 parts of antirust emulsion, 55 parts of plasticized acrylic emulsion, 13 parts of alcohol ester twelve, 23 parts of preservative, 4 parts of black paste, 95 parts of aluminum hydroxide, 45 parts of floating beads, 45 parts of talcum powder part and 45 parts of nano-montmorillonite / polypyrrole composite powder.

[0050] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0051] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd. Its solid content is 41±1%, pH is 7-7.5, glass transition temperature is 20°C, minimum film-forming temperature is 30°C, and viscosity is less than 20cps , with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good weather resistance and good corrosio...

Embodiment 3

[0060] A high anti-crack damping paint, calculated by weight parts, comprising the following raw materials:

[0061] 310 parts of acrylic waterproof emulsion, 105 parts of antirust emulsion, 45 parts of plasticized acrylic emulsion, 17 parts of alcohol ester twelve, 27 parts of preservative, 6 parts of black paste, 55 parts of aluminum hydroxide, 40 parts of magnesium hydroxide, floating beads 55 parts, 55 parts of talcum powder and 55 parts of nano-montmorillonite / polyaniline composite powder.

[0062] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0063] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd. Its solid content is 41±1%, pH is 7-7.5, glass transition temperature is 20°C, minimum film-forming temperature is 30°C, and viscosity is less than 20cps , with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good weather re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com