Chassis armor paint and preparation method thereof

A technology for armor and coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor aging resistance, easy dripping of asphalt, and gasoline resistance, etc., to achieve good stone impact resistance, good thermal insulation performance, and reduce The effect of stoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

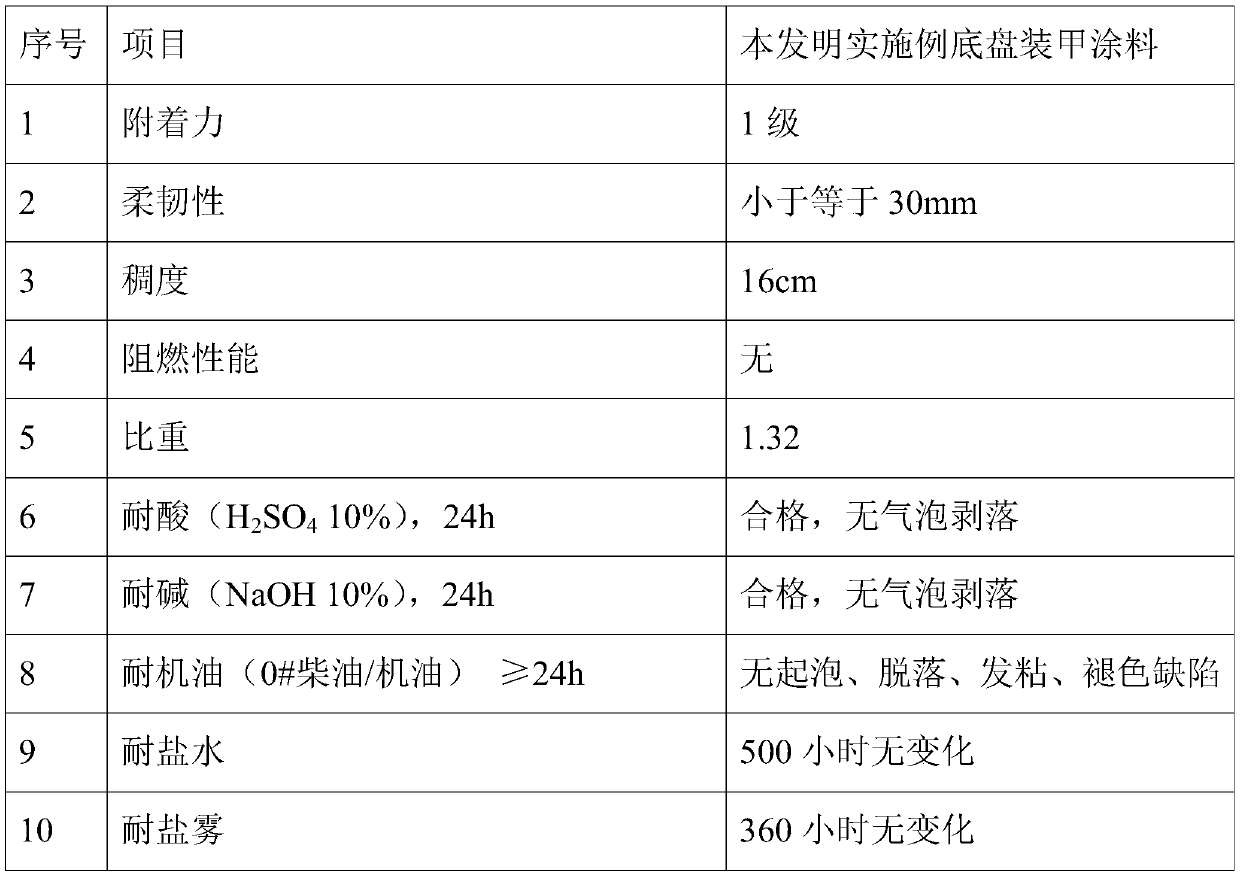

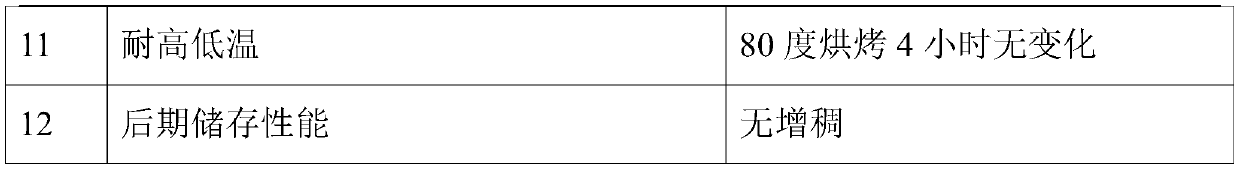

Examples

Embodiment 1

[0040] A chassis armor coating, calculated by weight parts, comprises the following raw materials:

[0041] 150 parts of styrene-acrylic emulsion, 60 parts of plasticized acrylic emulsion, 40 parts of waterproof emulsion, 50 parts of anti-rust emulsion, 150 parts of pure acrylic emulsion, 15 parts of film-forming aids, 25 parts of preservatives, 100 parts of fine sepiolite, bleaching 62.5 parts of beads, 100 parts of mica powder, 100 parts of talc powder, 50 parts of heavy calcium, 125 parts of silica powder, 25 parts of anti-corrosion filler and 5 parts of black paste.

[0042] Among them, the anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd., which has a solid content of 41±1%, a pH of 7-7.5, a glass transition temperature of 20°C, a minimum film-forming temperature of 30°C, and a viscosity of Less than 20cps, with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good...

Embodiment 2

[0063] A chassis armor paint, calculated by weight parts, comprises the following raw materials:

[0064] 145 parts of styrene-acrylic emulsion, 65 parts of plasticized acrylic emulsion, 35 parts of waterproof emulsion, 45 parts of antirust emulsion, 145 parts of pure acrylic emulsion, 13 parts of film-forming aids, 27 parts of preservatives, 95 parts of fine sepiolite, bleaching 60 parts of beads, 95 parts of mica powder, 95 parts of talc powder, 45 parts of heavy calcium, 120 parts of silica powder, 23 parts of anti-corrosion filler and 4 parts of black slurry.

[0065] Among them, the anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd., which has a solid content of 41±1%, a pH of 7-7.5, a glass transition temperature of 20°C, a minimum film-forming temperature of 30°C, and a viscosity of Less than 20cps, with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good weathe...

Embodiment 3

[0076] A chassis armor paint, calculated by weight parts, comprises the following raw materials:

[0077] 155 parts of styrene-acrylic emulsion, 55 parts of plasticized acrylic emulsion, 45 parts of waterproof emulsion, 55 parts of antirust emulsion, 155 parts of pure acrylic emulsion, 17 parts of film-forming aids, 23 parts of preservatives, 105 parts of fine sepiolite, bleaching 65 parts of beads, 105 parts of mica powder, 105 parts of talcum powder, 55 parts of heavy calcium, 130 parts of silica powder, 27 parts of anti-corrosion filler and 6 parts of black paste.

[0078] Among them, the anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd., which has a solid content of 41±1%, a pH of 7-7.5, a glass transition temperature of 20°C, a minimum film-forming temperature of 30°C, and a viscosity of Less than 20cps, with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss, good weat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com