Acrylic Emulsion for Damping Coatings

A technology of acrylic emulsion and damping paint, which is applied in the direction of coating, etc., can solve the problems of thickening of paint, unstable paint performance, salt spray resistance and corrosion resistance, and achieve the effect of increasing water retention and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

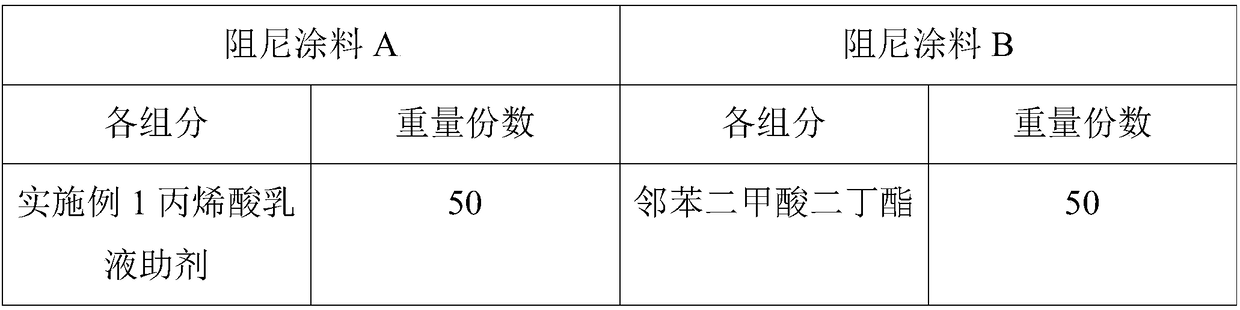

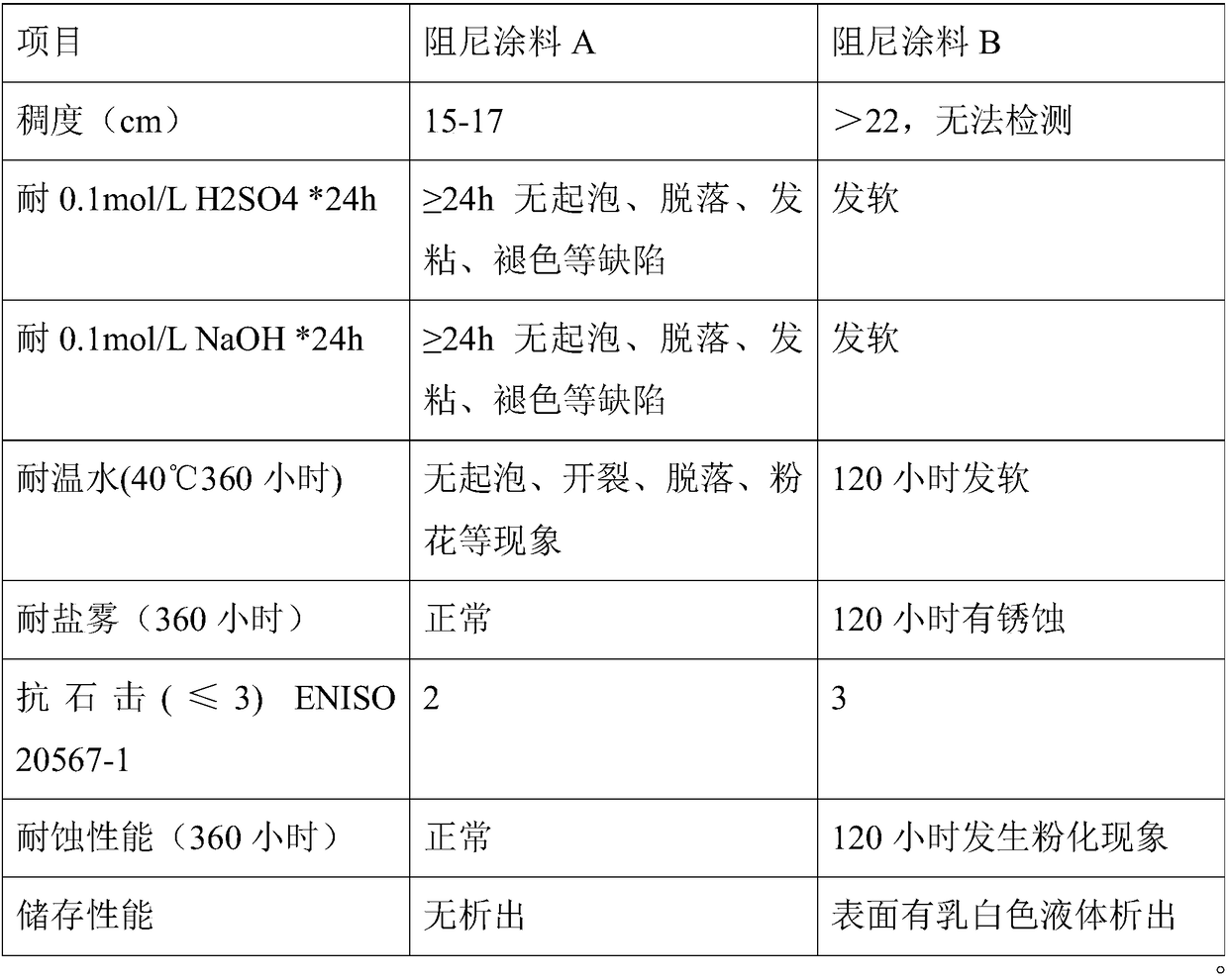

Examples

Embodiment 1

[0025] An acrylic emulsion for damping paint, calculated in parts by weight, including the following raw materials:

[0026] 160 parts of butyl acrylate, 100 parts of styrene, 40 parts of methyl methacrylate, 117 parts of α-ethylhexyl acrylate, 12 parts of methacrylic acid, 9 parts of ammonium acrylate, 15 parts of acrylonitrile, 422 parts of water, 1.7 parts of ammonium sulfate, 1.8 parts of oxidation-reduction initiator system, 2.5 parts of pH adjuster, 0.7 parts of emulsifier and 1.5 parts of chloromethyl isothiazolinone. Among them, the oxidation-reduction initiator system is composed of 0.8 part of inorganic reducing agent and 1 part of oxidizing agent, the oxidizing agent is tert-butyl hydroperoxide, and the inorganic reducing agent is sodium formaldehyde sulfoxylate.

[0027] Preparation:

[0028] It includes the following steps:

[0029] 1) Take 342 parts of water into the reactor, add 2.5 parts of pH adjuster and raise the temperature to 80°C, use 12 parts of water to dissol...

Embodiment 2

[0034] An acrylic emulsion for damping paint, calculated in parts by weight, including the following raw materials:

[0035] 150 parts of butyl acrylate, 90 parts of styrene, 35 parts of methyl methacrylate, 112 parts of α-ethylhexyl acrylate, 14 parts of methacrylic acid, 11 parts of ammonium acrylate, 17 parts of acrylonitrile, 390 parts of water, 1.2 parts of potassium sulfate, 1.4 parts of oxidation-reduction initiator system, 3 parts of pH adjuster, 0.5 parts of emulsifier and 2 parts of chloromethyl isothiazolinone, among which the oxidation-reduction initiator system consists of 0.6 parts of inorganic reducing agent and It is composed of 0.8 parts of oxidizing agent, the oxidizing agent is tert-butyl hydrogen peroxide, and the inorganic reducing agent is acetone sodium bisulfite.

[0036] The preparation method includes the following steps:

[0037] 1) Take 330 parts of water into the reactor, add 3 parts of pH adjuster and raise the temperature to 78℃, use 10 parts of water ...

Embodiment 3

[0042] An acrylic emulsion for damping paint, calculated in parts by weight, including the following raw materials:

[0043] 170 parts of butyl acrylate, 110 parts of styrene, 45 parts of methyl methacrylate, 122 parts of α-ethylhexyl acrylate, 10 parts of methacrylic acid, 8 parts of ammonium acrylate, 13 parts of acrylonitrile, 450 parts of water, 2.2 parts of sodium sulfate, 2.2 parts of oxidation-reduction initiator system, 4 parts of pH adjuster, 1 part of emulsifier and 1 part of chloromethyl isothiazolinone, of which the oxidation-reduction initiator system consists of 1 part of inorganic reducing agent and It is composed of 1.2 parts of oxidizing agent. The oxidizing agent is tert-butyl hydroperoxide and the inorganic reducing agent is sodium bisulfite.

[0044] The preparation method includes the following steps:

[0045] 1) Take 350 parts of water into the reactor, add 4 parts of pH adjuster and raise the temperature to 82°C, use 15 parts of water to dissolve 1.6 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com