Boron-containing silicon carbide fiber and preparation method thereof

A technology of silicon carbide fiber and polycarbosilane, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of uneven distribution of boron elements, complicated preparation processes, and complicated preparation processes of boron-containing precursors, and achieves short synthesis time. , The preparation process is simple, and the spinnability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In view of the current state of preparation of boron-containing silicon carbide fibers and the existing deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

[0025] An aspect of the embodiments of the present invention provides a method for preparing boron-containing silicon carbide fibers, which includes:

[0026] In a closed reaction vessel, a certain proportion of polysilocarbosilane and boron-containing monomers are synthesized under high temperature and high pressure to generate boron-containing polycarbosilane crude material, wherein the polysilocarbosilane is polydimethylsilane The low-molecular-weight product after high-temperature cracking is liquid at room temperature, with a molecular weight of less than 1000g / mol;

[0027] Dissolving an...

Embodiment 1

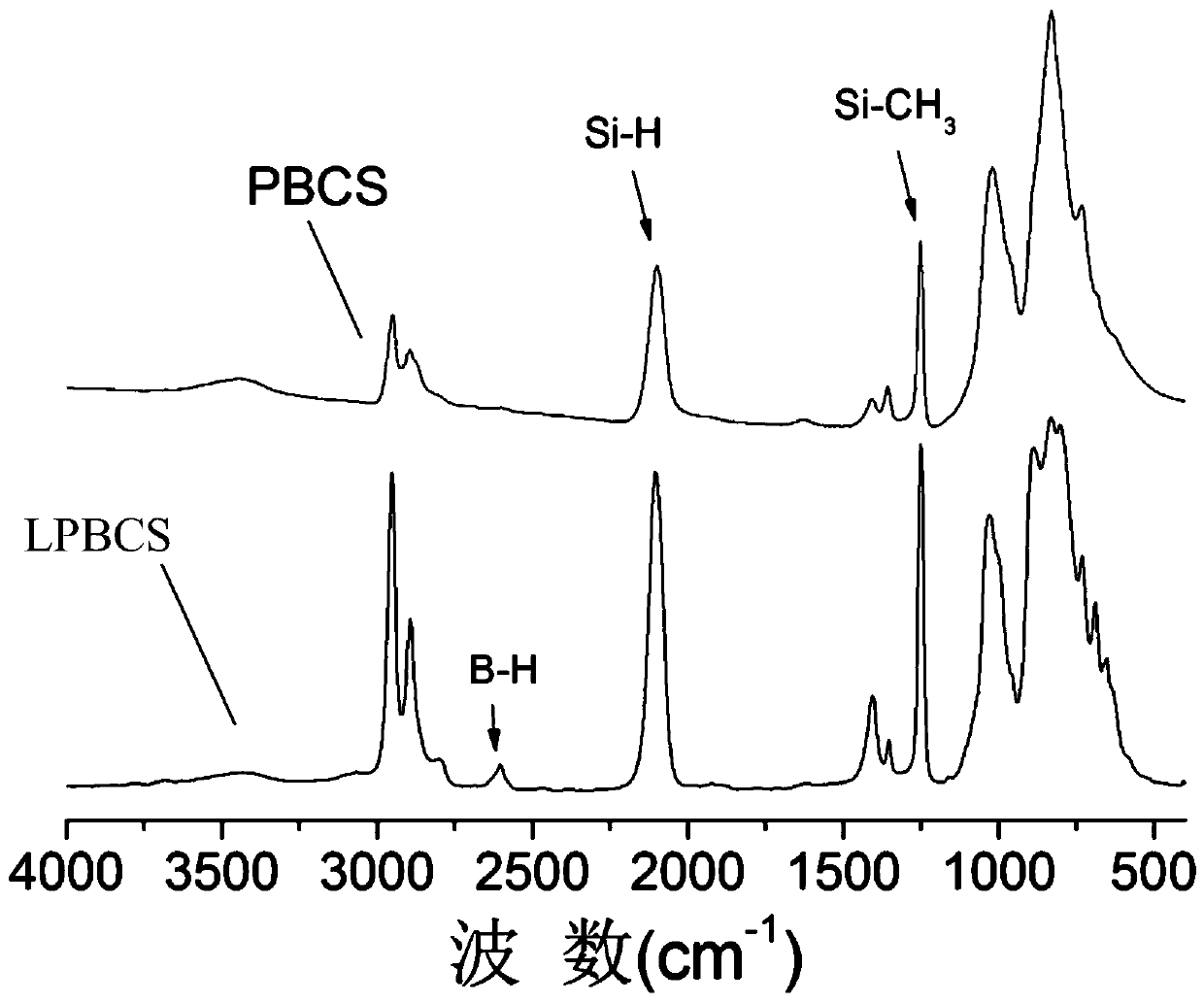

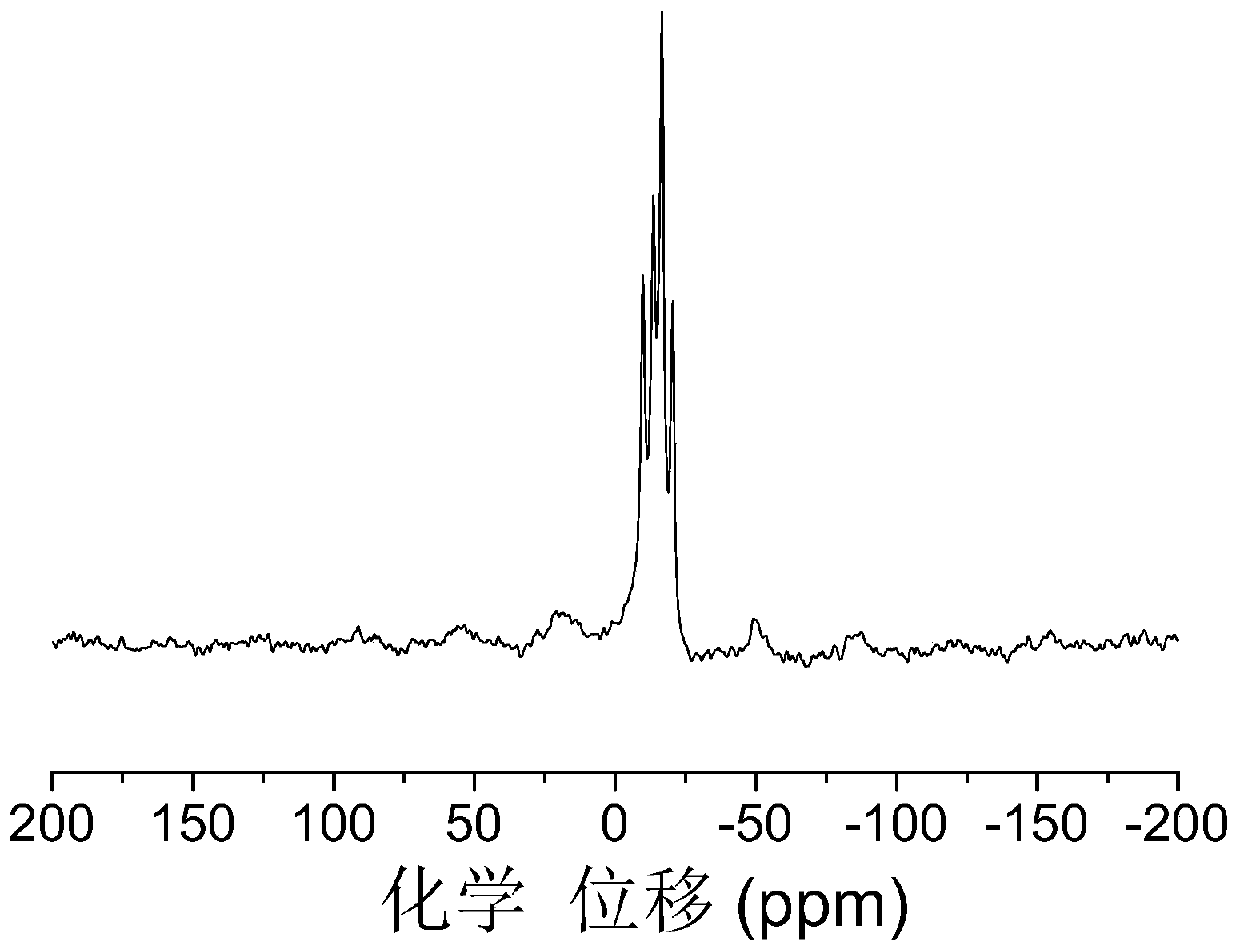

[0047] Polydimethylsilane is cracked at high temperature to obtain polysilocarbosilane, which has a molecular weight of 500 g / mol and is liquid at room temperature. Add 300g of liquid polysilocarbosilane and 3g of carborane into the closed device, replace the kettle with high-purity nitrogen three times, and then seal the device; then, start the temperature rise, raise the temperature to 400°C at a certain heating rate, stop the reaction after 6 hours, and react The final pressure is 8MPa. The reaction product was dissolved in xylene and filtered, and the solvent and small molecules were removed by distillation under reduced pressure to obtain boron-containing polycarbosilane (PBCS). For the convenience of comparison, the product obtained by taking the same mass of raw materials and reacting at 350°C for 2 hours is liquid boron-containing polycarbosilane (LPBCS). The infrared spectra of LPBCS and PBCS are as follows figure 1 shown. It can be seen that compared with LPBCS, P...

Embodiment 2

[0052] Add 300g of the liquid polysilocarbosilane in Example 1 and 2.5g of decaborane into the airtight container, replace the kettle with high-purity nitrogen three times, and then seal the device; then, start the temperature rise, and raise the temperature to 410°C at a certain heating rate , The reaction stopped after 4h, and the final pressure of the reaction was 7Mpa. The reaction product was dissolved in xylene and filtered, and the solvent and small molecules were removed by distillation under reduced pressure to obtain boron-containing polycarbosilane (PBCS02).

[0053] As determined by gel permeation chromatography (GPC), the number average molecular weight of PBCS02 is 1120 g / mol, and the softening point is 195°C.

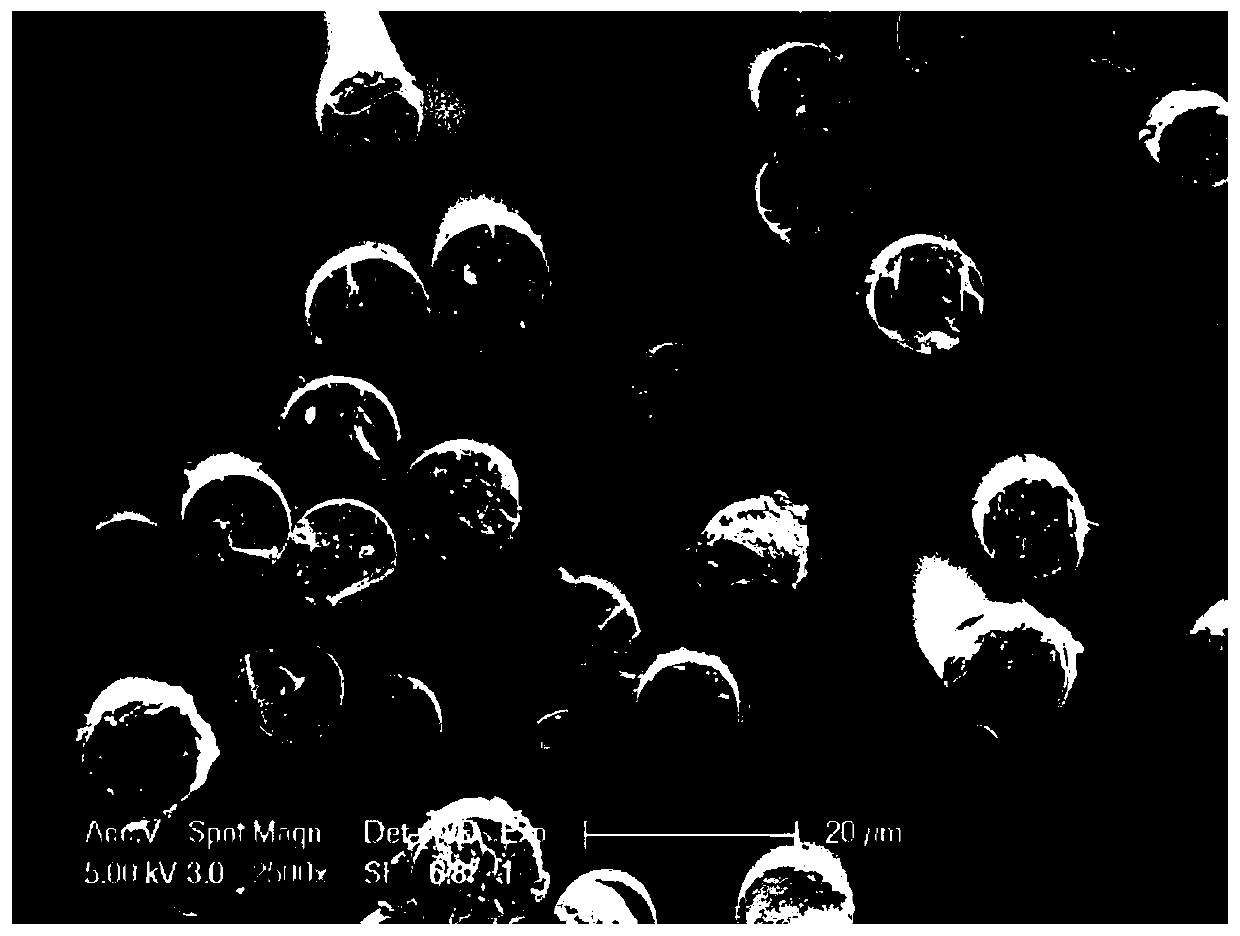

[0054] Melt-spinning the boron-containing polycarbosilane at 300° C. to obtain boron-containing polycarbosilane fibers. The boron-containing polycarbosilane fiber is infusible in air at 185°C for 5 hours to obtain boron-containing polycarbosilane infusib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com