Polytetrafluoroethylene membrane with supporting materials and preparation method thereof

A technology of polytetrafluoroethylene membrane and polytetrafluoroethylene, which is applied in the field of polytetrafluoroethylene hollow fiber membrane and its preparation, can solve problems such as difficult flow and poor processing performance, and achieve increased membrane area, low cost, and easy filling high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

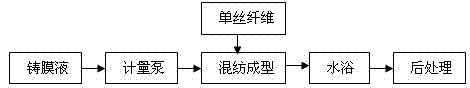

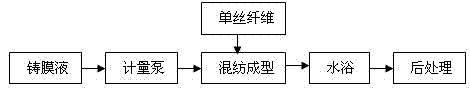

[0020] The steps of the preparation method of the polyethersulfone membrane with supporting material are as follows:

[0021] 1) Polytetrafluoroethylene concentrated dispersion emulsion with a concentration of 15-40 wt / v %, film-forming carrier polyvinyl alcohol with a concentration of 5-35 wt / v %, and inorganic fine powder with a concentration of 8-25 wt / v % Silicon dioxide, a viscosity regulator boric acid with a concentration of 0.03-0.06 wt / v%, and a defoamer with a concentration of 0.01-0.05 wt / v% are sequentially added to the melting pot, and the stirring shaft seal bar of the melting pot is opened. After fully stirring at 80-100°C for 15-24 hours, the casting solution is obtained;

[0022] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At the spinning speed of 15-40m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret for casting. Membrane liquid enters the hole, and ...

Embodiment 1

[0025] 1) Polytetrafluoroethylene concentrated dispersion emulsion with a concentration of 15 wt / v%, film-forming carrier polyvinyl alcohol with a concentration of 5 wt / v%, and inorganic micropowdered silica with a concentration of 8 wt / v%. Add 0.03 wt / v % viscosity regulator boric acid and 0.01 wt / v % tributyl phosphate to the melting pot in sequence, open the sealing bar of the stirring shaft of the melting pot, and fully stir at 80°C for 15 hours to obtain Casting solution;

[0026] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At a spinning speed of 15m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret casting solution Enter the hole, and the monofilament fiber entering the spinneret from the monofilament fiber entering hole and the deionized water in the core liquid entering the hole are compounded and formed in the spinneret, and then walk vertically 5cm downward in ...

Embodiment 2

[0029] 1) Polytetrafluoroethylene concentrated dispersion emulsion with a concentration of 40 wt / v %, film-forming carrier polyvinyl alcohol with a concentration of 35 wt / v %, and inorganic micropowder silica with a concentration of 25 wt / v %. Add 0.06 wt / v % viscosity modifier boric acid and 0.05 wt / v % polydimethylsilane into the melting pot in sequence, open the stirring shaft sealing bar of the melting pot, and stir fully at 100°C for 24 hours, Obtain casting solution;

[0030] 2) Squeeze the casting solution into the tubular hollow fiber spinning spinneret. At the spinning speed of 40m / min, the casting solution is extruded by air pressure, filtered through the filter and metering pump into the spinneret casting solution Enter the hole, and the monofilament fiber entering the spinneret from the monofilament fiber entering hole and the deionized water in the core liquid entering the hole are compounded and formed in the spinneret, and then walk vertically 60cm downward in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com