Organic-inorganic hybrid silane metal waterborne anti-corrosion coating and preparation method thereof

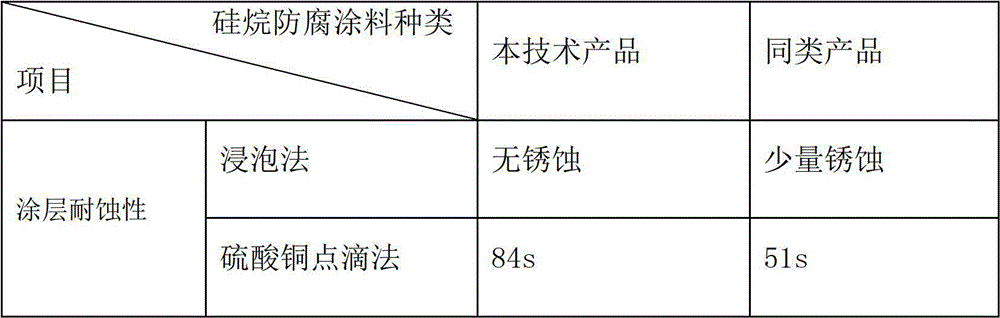

A technology of anti-corrosion coatings and hybrid silanes, applied in the direction of anti-corrosion coatings, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of poor wettability, not very mature, insufficient stability, etc., to improve anti-oxidation performance, Improve anti-corrosion performance, improve toughness and adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

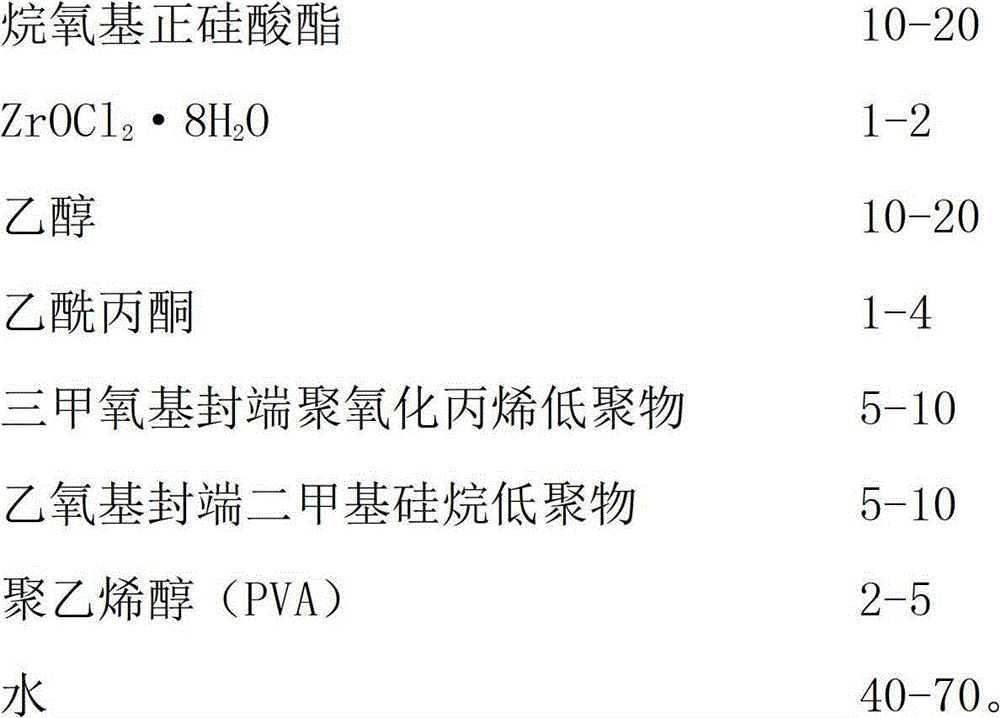

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The anticorrosion coating preparation that is suitable for the metal surface spraying of large workpiece

[0030] Including the following steps:

[0031] 1. Add alkoxy orthosilicate (10 parts) and ethanol (5 parts) into water (56 parts), stir well to form a mixed solution A;

[0032] 2. Add trimethoxy-terminated polyoxypropylene silane oligomer (5 parts), ethoxy-terminated dimethylsilane oligomer (6 parts), and acetylacetone (1 part) into the mixture A, and stir After homogenization, mixture B is formed;

[0033] 3. Adjust the pH value of the mixture B to 8-10 with sodium hydroxide solution, raise the temperature to 30-50° C., and stir in a sealed environment for not less than 2 hours to obtain silica sol C.

[0034] 4. Add ZrOCl 2 ·8H 2 O (2 parts), acetylacetone (1 part), ethanol (6 parts), and water (3 parts) were mixed uniformly in proportion, and stirred at room temperature for 2 hours to prepare zirconium sol D.

[0035] 5. Mix the above-mention...

Embodiment 2

[0036] Embodiment 2: Preparation of anti-corrosion coating suitable for spraying metal surfaces of large workpieces.

[0037] Including the following steps:

[0038] 1. Add alkoxy orthosilicate (20 parts) and ethanol (10 parts) into water (39 parts), stir well to form a mixed solution A;

[0039] 2. Add trimethoxy-terminated polyoxypropylene silane oligomer (5 parts), ethoxy-terminated dimethylsilane oligomer (8 parts), and acetylacetone (1 part) into the mixture A, and stir After homogenization, mixture B is formed;

[0040] 3. Adjust the pH value of the mixture B to 8-10 with sodium hydroxide solution, raise the temperature to 30-50° C., and stir in a sealed environment for not less than 2 hours to obtain silica sol C.

[0041] 4. Add ZrOCl 2 ·8H 2 O (2 parts), acetylacetone (1 part), ethanol (6 parts), and water (5 parts) were mixed uniformly in proportion, and stirred at room temperature for 2 hours to prepare zirconium sol D.

[0042]5. Mix the above-mentioned silica...

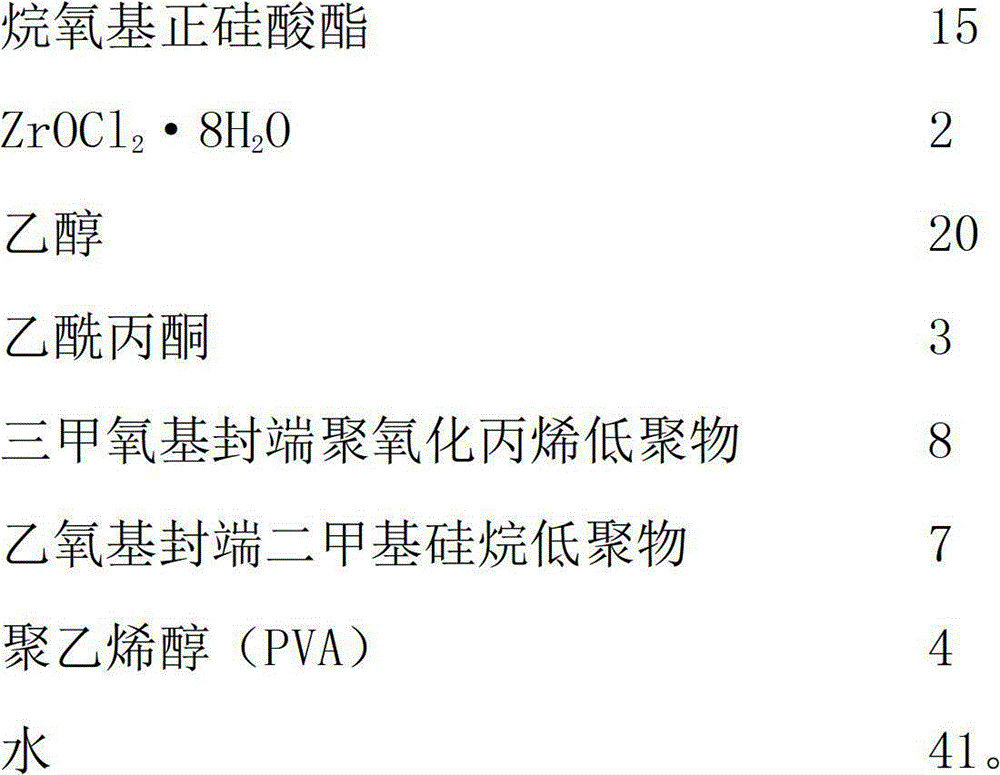

Embodiment 3

[0043] Embodiment 3: be applicable to the anticorrosion coating preparation of various brushing techniques

[0044] Including the following steps:

[0045] 1. Add alkoxy orthosilicate (10 parts) and ethanol (5 parts) into water (66 parts), stir well to form a mixed solution A;

[0046] 2. Add trimethoxy-terminated polyoxypropylene silane oligomer (8 parts), ethoxy-terminated dimethylsilane oligomer (10 parts), and acetylacetone (2 parts) into the mixture A, and stir After homogenization, mixture B is formed;

[0047] 3. Adjust the pH value of the mixture B to 4 with hydrochloric acid, raise the temperature to 30-50°C, and stir in a sealed environment for not less than 2 hours to obtain the silica sol C.

[0048] 4. Add ZrOCl 2 ·8H 2 O (2 parts), acetylacetone (1 part), ethanol (4 parts), and water (4 parts) were mixed uniformly in proportion, and stirred at room temperature for 2 hours to prepare zirconium sol D.

[0049] 5. Mix the above-mentioned silica sol C and zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com