Method for directly repairing and regenerating positive electrode material of waste lithium iron phosphate battery

A lithium iron phosphate battery, repair and regeneration technology, applied in battery electrodes, secondary batteries, battery recycling and other directions, can solve the problems of high energy consumption, use of positive electrode materials, etc., to reduce pollution and energy consumption, improve recycling efficiency, The effect of high economic driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

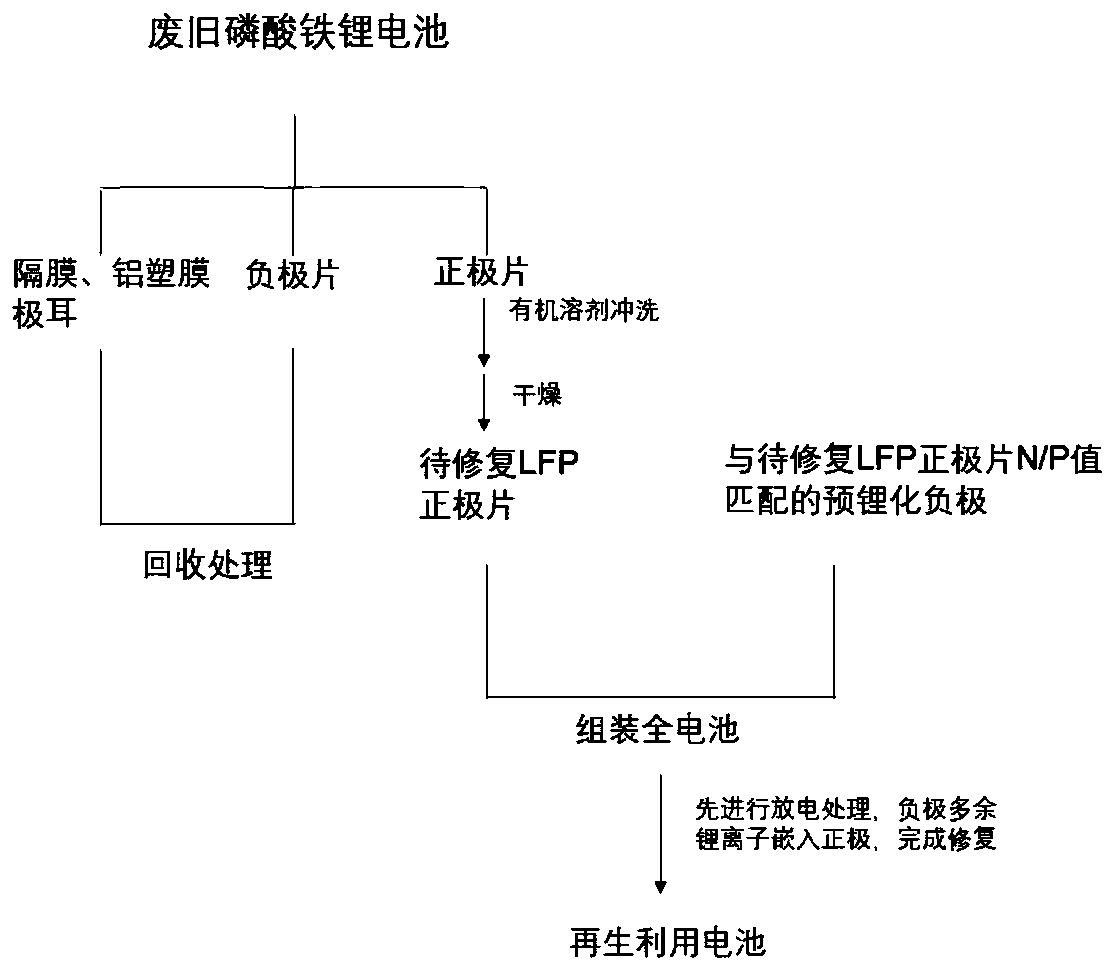

[0032] (1) Dismantling of waste lithium-ion batteries and recycling of cathode materials

[0033] After the waste lithium-ion battery is dismantled step by step, the positive electrode, negative electrode, and diaphragm are separated; 1g of the positive electrode piece is separated, and the recovered positive electrode material is obtained after washing with 20mL of dimethyl carbonate;

[0034] (2) Use ICP-MS to test the lack of lithium ions in the waste electrode sheet, use an analytical balance to weigh the loading capacity and surface capacity per unit area of the electrode sheet; then weigh the quality of the positive electrode material obtained, and calculate the loading capacity per unit area and Positive electrode theoretical capacity per unit area; use an analytical balance to weigh the loading capacity and surface capacity per unit area of the electrode sheet.

[0035] (3) Preparation of pre-lithiated graphite negative electrode

Embodiment 2

[0042] Other steps are identical with embodiment 1, and difference is that the step of preparing pre-lithiated graphite negative electrode in step (3) is as follows:

[0043] 3-a) Put metal lithium powder into a sealed tank filled with an inert atmosphere, heat it to 180-200°C to make metal lithium into molten lithium, and use sputtering equipment to cool rapidly to obtain uncoated metal Lithium powder;

[0044] 3-b) Will (NH 4 ) 2 HPO 4 , Li 2 C 2 o 4 , Al(NO 3 ).9H 2 Add O into the propanol solvent and stir at room temperature. After the drug is completely dissolved, add tetrabutyl titanate and continue stirring to obtain a sol. The spherical lithium aluminum titanium phosphate (LATP) precursor is obtained by spray drying. , and then calcined at 900 °C for 1 h in an air atmosphere to obtain spherical LATP powder; polyacrylonitrile (PAN) and LiClO 4 Add it into dimethylformamide (DMF), add LATP powder after it is completely dissolved, and stir at 80°C for 6 hours to ...

Embodiment 3

[0048] Other steps are identical with embodiment 1, and difference is that the step of preparing pre-lithiated graphite negative electrode in step (3) is as follows:

[0049] In a dry environment, use a roller press to press the lithium foil to a thickness of 3-5 μm, then gently press the pressed lithium foil on the graphite negative electrode sheet, and the preparation of the pre-lithiated graphite negative electrode is completed. The deficient amount of lithium in the waste lithium iron phosphate positive electrode is in excess of 5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com