Method for preparing monocrystal metal foil

A technology of metal foil and polycrystalline metal, which is applied in the field of preparing single crystal metal foil, can solve the problems of tediousness, high energy consumption, and high difficulty, and achieve the effects of strong universality, low energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example is used to illustrate the preparation of single crystal copper foil from polycrystalline copper foil.

[0049] 1. Cut the copper foil with a purity of 99.99% purchased from Aluminum Corporation of China into strips with a width of about 2 cm, a length of about 15 cm, and a thickness of 20 microns.

[0050] 2. Put the strip-shaped copper foil that has been cut into the metal thermal evaporation system purchased from Beijing Micro-Nano Vacuum Technology Co., Ltd., model VZB-400, and sandwich it between two copper metal electrodes, so that The copper foil is set vertically, and the vacuum is evacuated to 5×10 by mechanical pump and molecular pump -5 Pa.

[0051] 3. Heat the two electrodes until the central temperature of the strip-shaped copper foil is 1025±5°C, and keep it for 8 hours, wherein the heating rate is 8°C / min.

[0052] 4. Cool down to room temperature at a rate of 8°C / min.

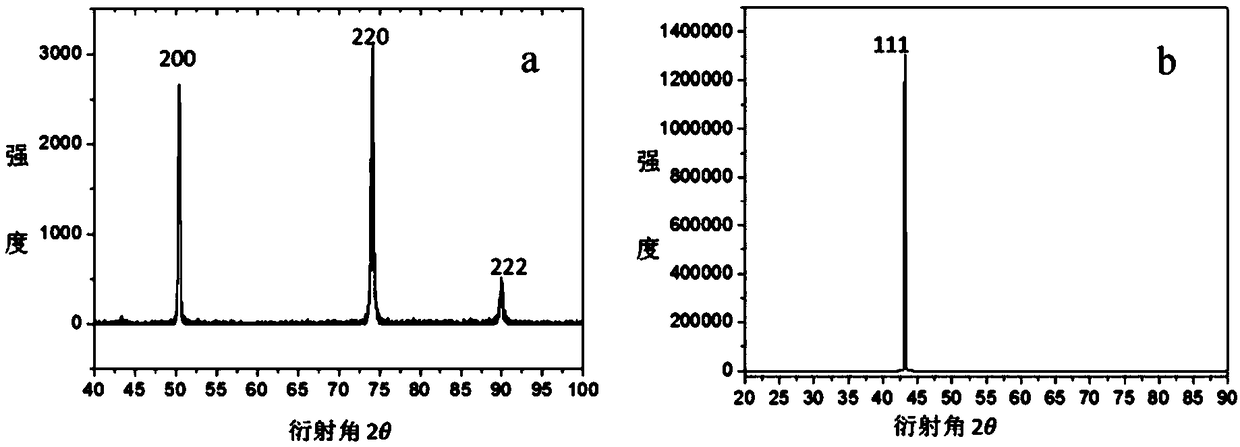

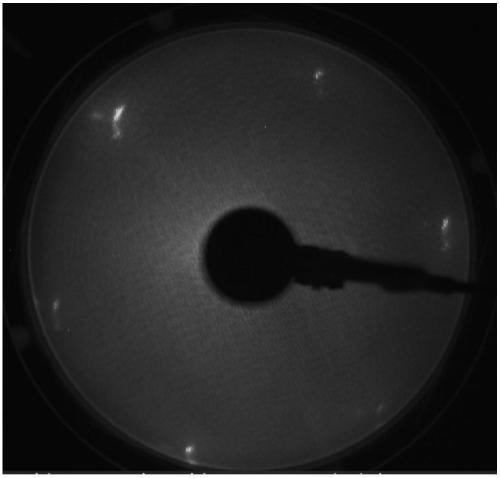

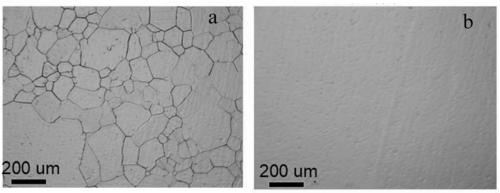

[0053] Adopt XRD to characterize the untreated polycrystalline copper ...

Embodiment 2

[0057] This example is used to illustrate the preparation of single crystal nickel foil from polycrystalline nickel foil.

[0058] 1. The nickel foil with a purity of 99.9% purchased from Aluminum Corporation of China was cut into strips with a width of about 1 cm, a length of about 15 cm, and a thickness of 10 microns.

[0059] 2. Put the strip-shaped nickel foil that has been cut into the metal thermal evaporation system of the model VZB-400 purchased from Beijing Micro-Nano Vacuum Technology Co., Ltd., and sandwich it between two nickel metal electrodes , so that the nickel foil is vertically set, vacuumed to 5×10 by mechanical pump and molecular pump -5 Pa.

[0060] 3. Heat the two electrodes until the central temperature of the strip-shaped nickel foil is 1375±5°C, and keep it for 10 hours, wherein the heating rate is 12°C / min.

[0061] 4. Cool down to room temperature at a rate of 12°C / min.

[0062] The untreated polycrystalline nickel foil prepared in step (1) and th...

Embodiment 3

[0065] This example is used to illustrate the preparation of single crystal ruthenium foil from polycrystalline ruthenium foil.

[0066] 1. Cut ruthenium foil with a purity of 99.99% purchased from Aluminum Corporation of China into strips with a width of about 3 cm, a length of about 30 cm, and a thickness of 50 microns.

[0067] 2. Put the cut strip-shaped ruthenium foil into a vertical tube furnace of model OTF-1200X-S-VT purchased from Hefei Kejing, place the ruthenium foil vertically, and feed hydrogen and argon A hydrogen-argon mixture with a gas volume ratio of 1:9 was used as the protective gas.

[0068] 3. Raise the temperature to 2260±5°C and keep it for 10 hours, wherein the heating rate is 12°C / min.

[0069] 4. Cool down to room temperature at a rate of 12°C / min.

[0070] The untreated polycrystalline ruthenium foil prepared in step (1) and the treated ruthenium foil prepared in Example 3 were characterized by XRD. The results show that the treated ruthenium foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com