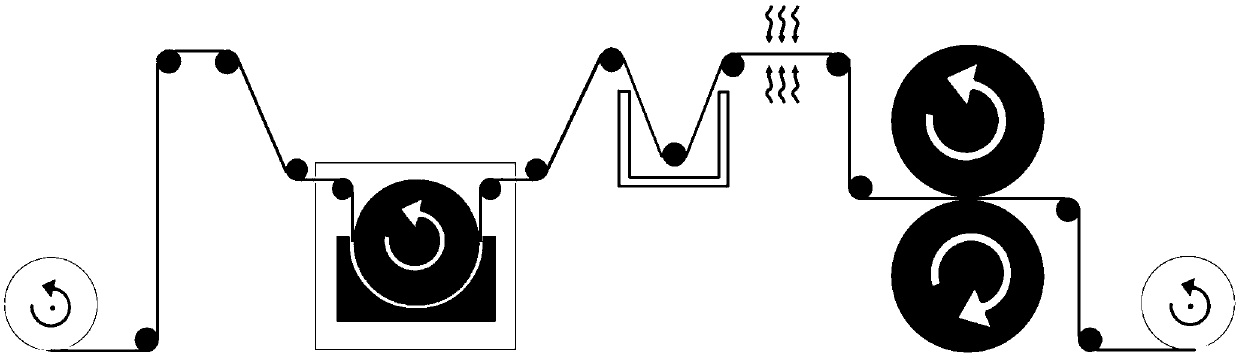

Continuous, controllable and effective pre-lithiation system and lithium supplementing method

A pre-lithiation and lithiation technology, used in non-aqueous electrolyte battery electrodes, electrical components, battery electrodes, etc., can solve the problems of poor cycle performance, low coulomb efficiency in the first cycle, and low capacity, and achieve a controllable and excellent degree. Electrochemical performance, uniform effect of lithiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

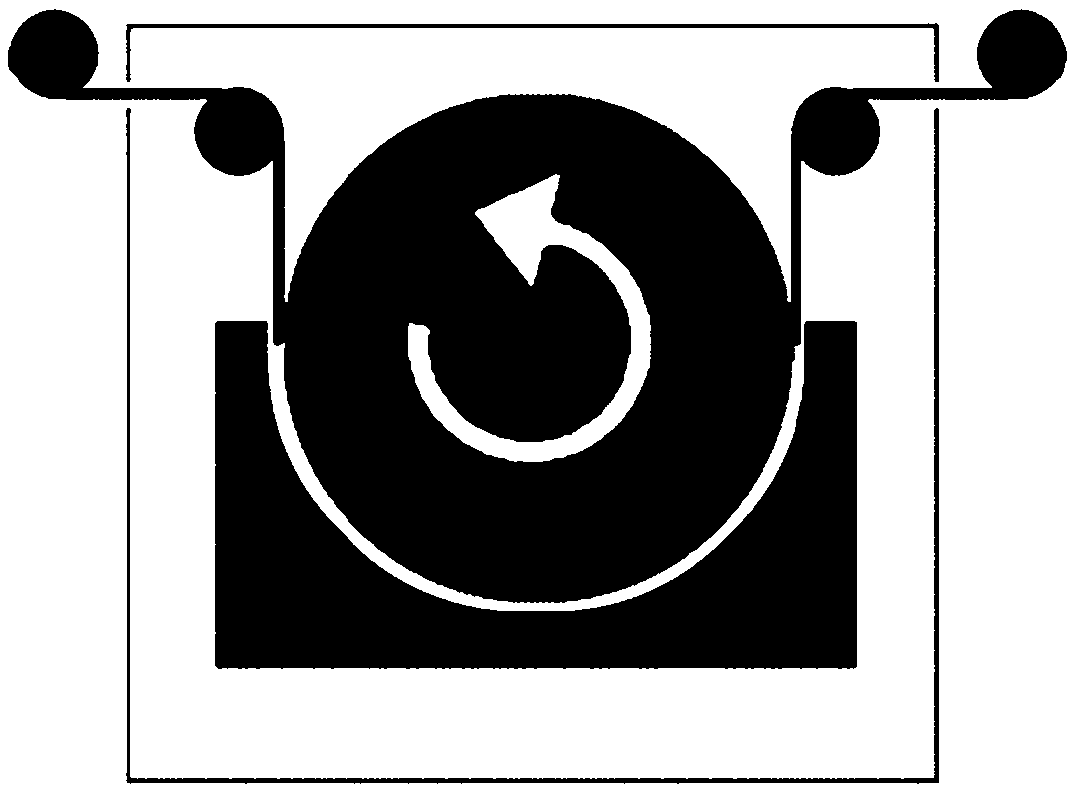

[0029] Install the coated and dried silicon-carbon composite negative electrode coil with a theoretical capacity of 700 mAh per gram on the unwinding device, install the lithium ingot or lithium ribbon on the roller, and then coat the carbon nanotube film On the surface of lithium ingots or lithium strips, the rollers of the indirect lithiation device are formed, and the silicon-carbon composite negative electrode rolls are respectively attached to the surface of the rollers of the indirect lithiation device by traction, passing through the electrolyte and cleaning device in the negative pressure indirect lithiation device , drying device, rolling device and winding device, start the system to start negative pressure lithiation; wherein lithium hexafluorophosphate with a concentration of 2 moles per liter is selected as the electrolyte for lithiation for 30 minutes.

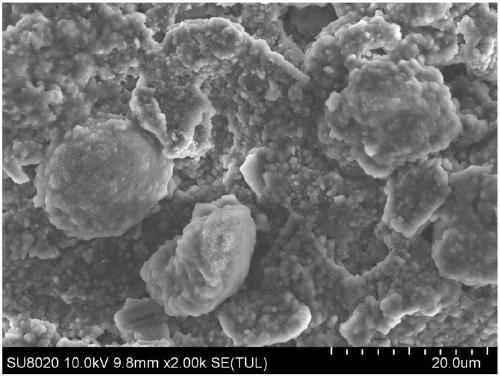

[0030] The surface morphology of the lithiated silicon anode was characterized by scanning electron microscopy,...

Embodiment 2

[0032] Install the coated and dried silicon-carbon composite negative electrode coil with a theoretical capacity of 700 mAh per gram on the unwinding device, and pass through the negative pressure indirect lithiation device, cleaning device, drying device, and roller press respectively after being drawn. device and winding device, start the system to start lithiation; wherein the lithium hexafluorophosphate solution with a concentration of 0.5 moles per liter is selected for lithiation for 30 minutes. The electrochemical performance test results of the obtained materials are listed in Table 1.

Embodiment 3

[0038] Install the coated and dried silicon-carbon composite negative pole coil with a theoretical capacity of 1000 mAh per gram on the unwinding device, and then pass through the negative pressure indirect lithiation device, cleaning device, drying device, and roller pressing device respectively through traction. device and winding device, start the system to start lithiation under negative pressure conditions; wherein a lithium hexafluorophosphate solution with a concentration of 5 moles per liter is selected for lithiation for 60 minutes. The electrochemical performance test results of the obtained materials are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com