Method of hydrogenation treatment for coal tar by hypercritical solvent

A technology of hydrotreating and coal tar, applied in tar processing through distillation, petroleum industry, refined hydrocarbon oil, etc., can solve problems such as less research on light weight modification, inability to guide industrial production, and easy coking of the process, etc. Achieve the effects of reducing device and operating costs, less environmental pollution, and simple operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

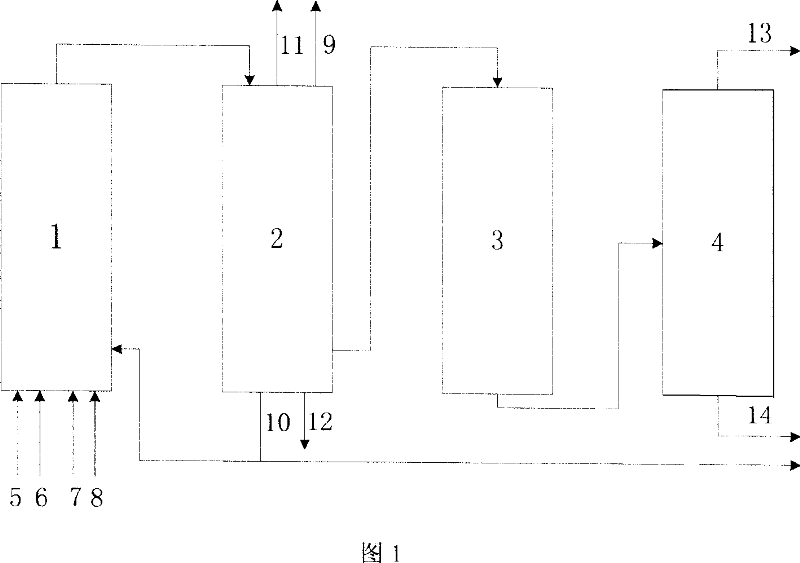

Method used

Image

Examples

Embodiment 1

[0028] Coal tar raw material is added in the reactor, and adding is the catalyst B of the solvent A of 1: 1 and the catalyst B of coal tar raw material 16wt% with coal tar raw material volume ratio; Said solvent A is xylene, and said catalyst B is Ni10 %Mo1%-Y type molecular sieve catalyst; carry out lightening reaction in the presence of hydrogen, the conditions of hydrogenation lightening in the supercritical solvent are: temperature 400 ℃, pressure 8MPa, filling hydrogen pressure is 2MPa, The reaction time is 20 minutes.

[0029] The liquid product from the reactor is separated and the solvent is cut to obtain heavy oil and light oil fractions. The specific steps are to distill the liquid product in the reactor to cut water, light oil, solvent and heavy oil.

[0030] The heavy oil cut out through distillation can continue to be returned to the reactor for reaction.

[0031] Said light oil fraction cut out through distillation solvent can be further refined and cut out gaso...

Embodiment 2

[0033] The coal tar raw material is added in the reactor, and adding is the catalyst B of the solvent A of 1: 1 and the coal tar raw material 16wt% with the coal tar raw material volume ratio; Said solvent A is xylene, and said catalyst B is Pd. .1%Ni10%Mo1%-Y molecular sieve catalyst; carry out lightening reaction in the presence of hydrogen, the conditions of hydrogenation lightening in the supercritical solvent are: temperature 400 ° C, pressure 8MPa, filled with hydrogen pressure It is 2MPa, and the reaction time is 20min.

[0034] The liquid product from the reactor is distilled to cut off heavy oil and light oil fractions, and the specific steps are to distill the liquid product in the reactor to cut off water, light oil, solvent and heavy oil. The heavy oil cut out through distillation can continue to be returned to the reactor for reaction.

[0035] The light oil fraction cut out by distillation can be further refined and cut out gasoline fraction and diesel oil fract...

Embodiment 3

[0037]Coal tar raw material is added in the reactor, and adding is the catalyst B of the solvent A of 1: 1 and the catalyst B of coal tar raw material 2wt% with coal tar raw material volume ratio; Said solvent A is xylene, and said catalyst B is Co5 %Mo0.5%-Y type molecular sieve catalyst; carry out lightening reaction in the presence of hydrogen, the conditions of hydrogenation lightening in the supercritical solvent are: temperature 376 ° C, pressure 7.6MPa, filled with hydrogen pressure It is 2MPa, and the reaction time is 20min.

[0038] The liquid product from the reactor is distilled to cut off heavy oil and light oil fractions, and the specific steps are to distill the liquid product in the reactor to cut off water, light oil, solvent and heavy oil.

[0039] The heavy oil cut out through distillation can continue to be returned to the reactor for reaction.

[0040] The light oil fraction cut out by distillation can be further refined and cut out gasoline fraction and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com