Ultrasonic water immersion automatic detection device and method for complex ring forgings

An automatic detection and ring forging technology, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve poor detection capabilities, chaotic detection signals, and inability to realize real-time imaging And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

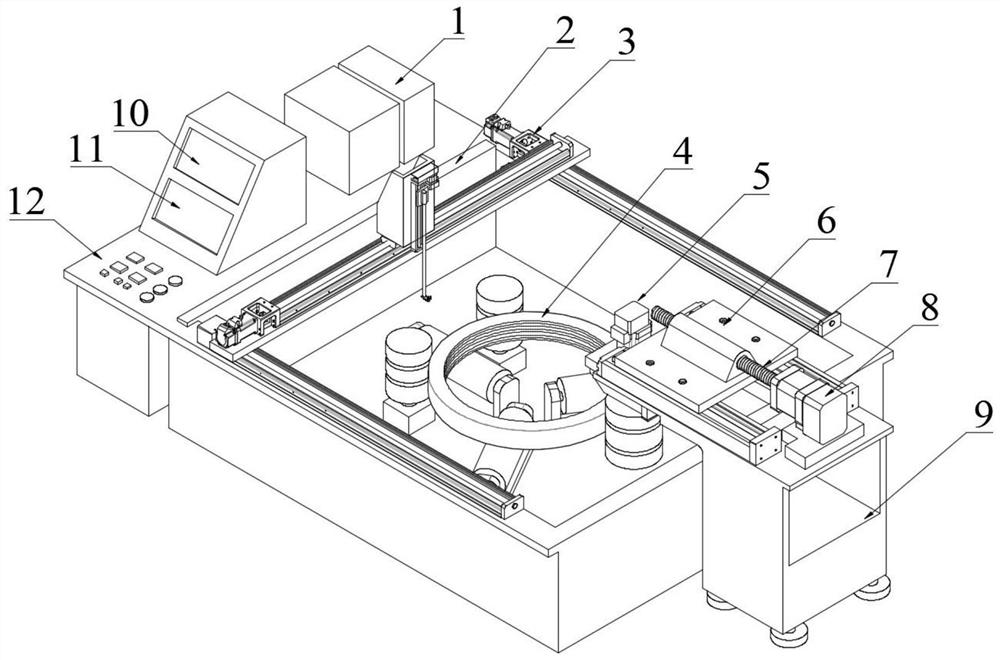

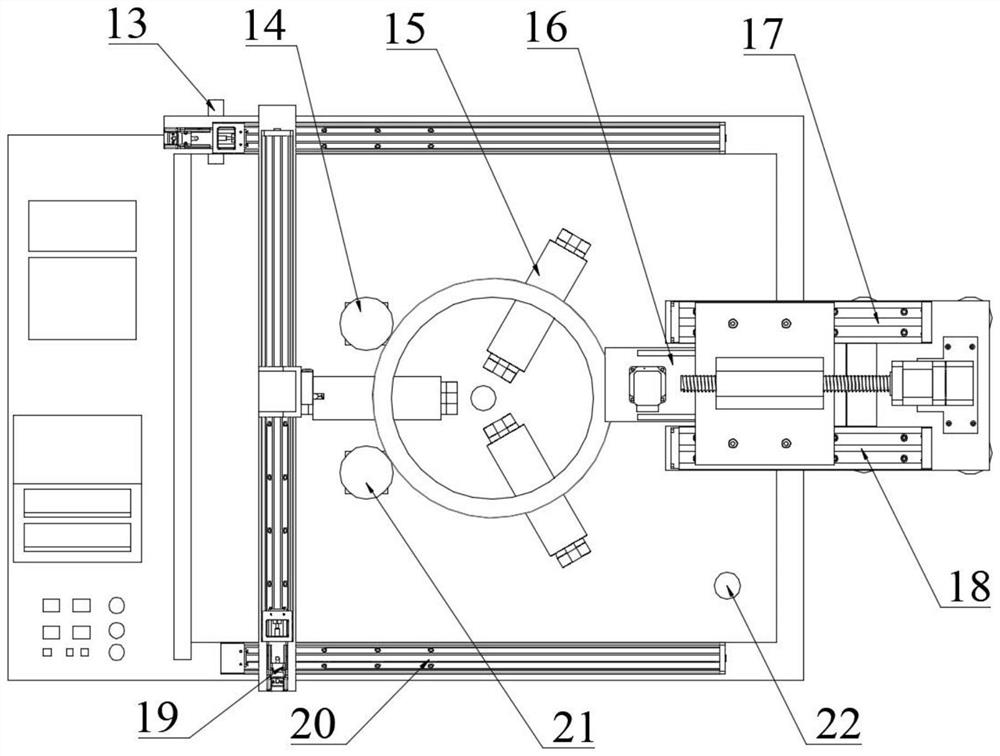

[0115] The method for performing ultrasonic automatic detection of complex ring forgings through the above-mentioned detection device mainly includes the following steps:

[0116] Step1: According to the thickness of complex ring forgings, ultrasonic phased array single detection is used for thin-walled parts, and ultrasonic phased array and multi-frequency array water immersion ultrasonic composite detection is used for thick-walled parts twice;

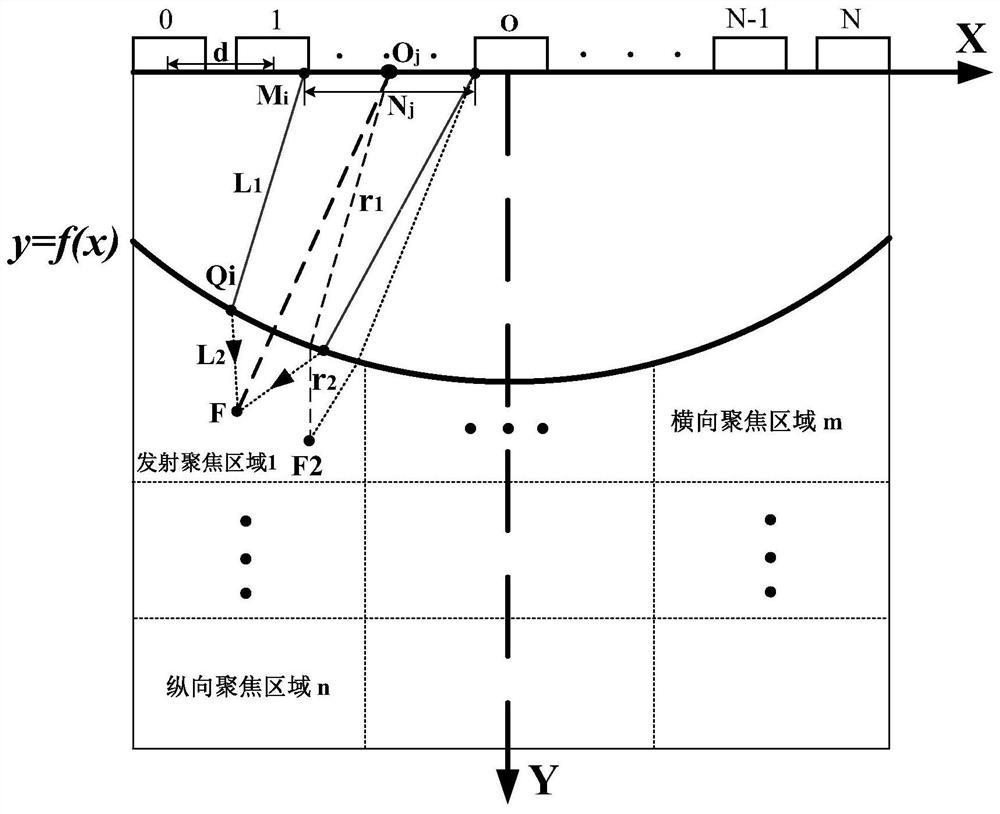

[0117] Step2: According to the profile shape of the cross section of the complex ring forging 4, fit the profile function of the section, reasonably divide the detection area under the probe into m×n areas, and determine the optimal emission dynamic aperture array center and center of each detection area according to the dynamic aperture design method For the number of array elements, the transmission delay time of each area array is determined according to the calculation method of the surface multimedia transmission focusing delay ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com