Method for controlling size uniformity of hot rolled high-carbon austenitic stainless steel grains

A technology of carbon austenite and grain size, which is applied in the field of controlling the uniformity of grain size of hot-rolled high-carbon austenitic stainless steel, can solve the problem of deteriorating mechanical properties and corrosion resistance, deteriorating high-temperature strength and fatigue properties of materials, and no Discuss issues such as the uniformity of the thickness of the structure to achieve the effects of strong operability, avoiding carbide precipitation, and avoiding abnormal growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

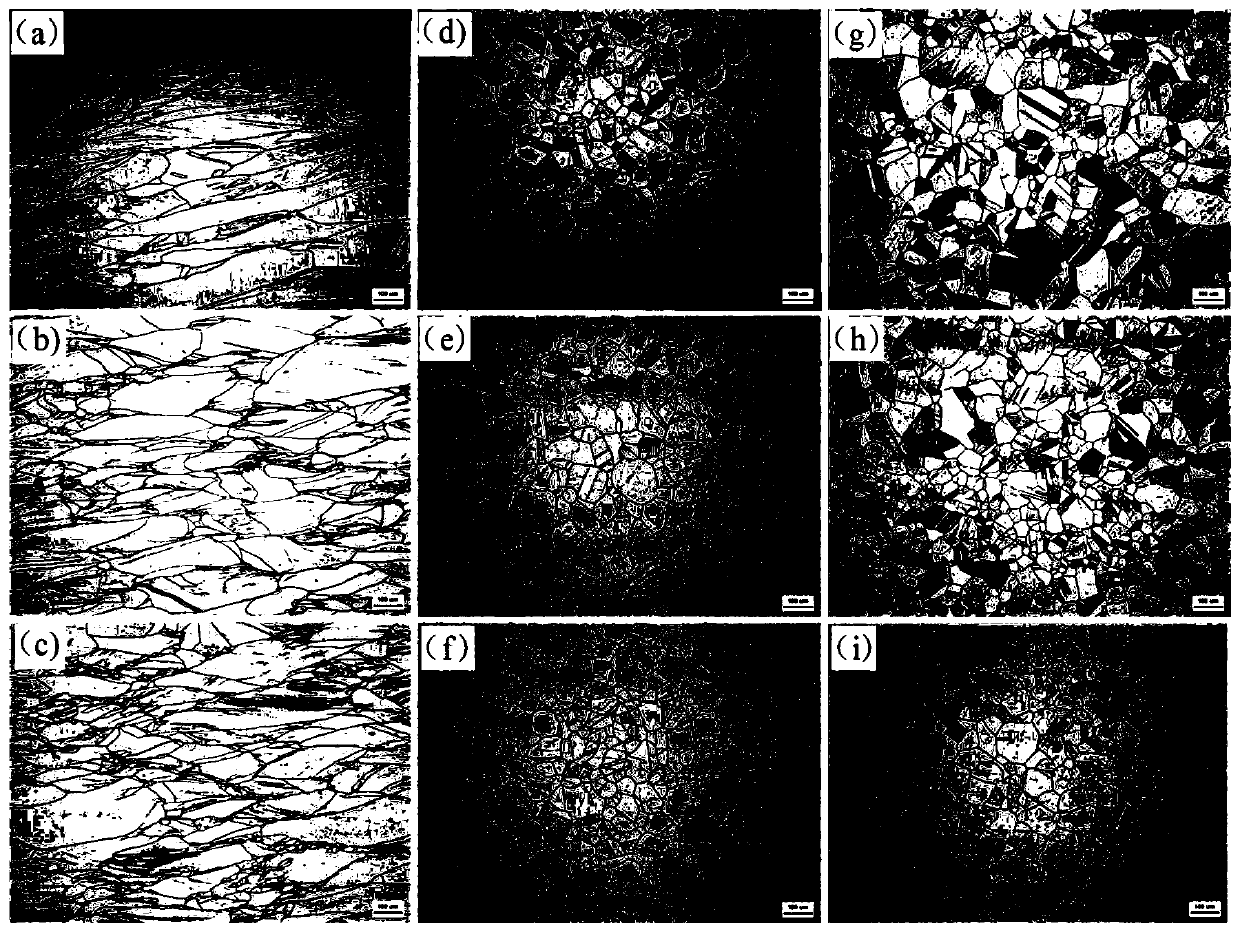

[0030] The brand of high-carbon austenitic stainless steel hot-rolled medium and heavy plate is 07Cr17Ni12Mo2, the unified code is S31609, the mass percentage contains 0.04 ~ 0.1wt% C, the thickness is 70mm, and the microstructure at different positions in the thickness direction is as follows: figure 1 (a), (b) and (c);

[0031] Place the high-carbon austenitic stainless steel hot-rolled medium-thick plate in a heating furnace and preheat it at 900°C for a preheating time t1=0.5h=35min to obtain a preheated plate;

[0032] Raise the temperature of the preheating plate to 1000°C with the furnace for recrystallization treatment, control the heating rate of 1-5°C / min; recrystallization treatment time t2 = 0.6h = 42min, and then obtain the recrystallization plate;

[0033] The recrystallized plate is heated to 50°C with the furnace for solution treatment, and the heating rate is controlled at 1-5°C / min; the solution treatment time t3 = 0.4h = 8min, and then the solid solution pla...

Embodiment 2

[0036] Raw material and method are with embodiment 1, difference is:

[0037] (1) Take out the preheating plate and wrap it with asbestos, then raise the temperature of the heating furnace to 1000°C, and then place the preheating plate in the heating furnace for recrystallization treatment; when the asbestos is wrapped, control the cooling rate of the preheating plate to 1-5 ℃ / min, the wrapping time of the preheating plate in asbestos is ≤20min;

[0038] (2) Take out the recrystallization plate and wrap it with asbestos, then raise the temperature of the heating furnace to 50-90°C, and then place the recrystallization plate in the heating furnace for solid solution treatment; 5°C / min, the wrapping time of the recrystallized plate in asbestos is ≤20min;

[0039] (3) The microstructure of the high carbon austenitic stainless steel plate after solution treatment is as follows: figure 1 As shown in (g), (h) and (i), the average grain sizes of the surface layer, quarter and core ar...

Embodiment 3

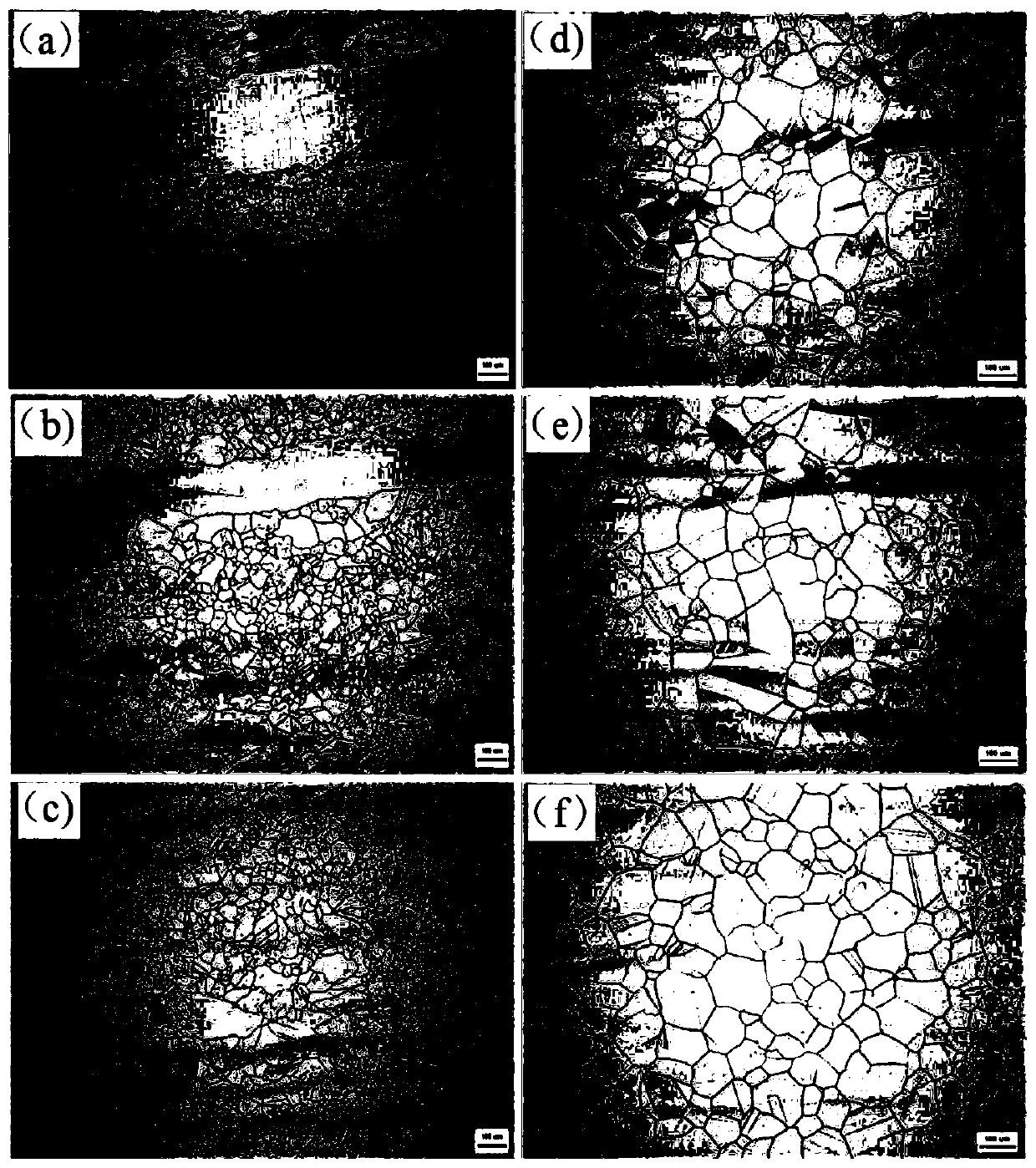

[0041] The brand of high-carbon austenitic stainless steel hot-rolled plate is 06Cr25Ni20, unified code S31008, containing 0.08% C by mass percentage, thickness 50mm, and the microstructure at different positions in the thickness direction are as follows: figure 2 (a), (b) and (c);

[0042] Method is with embodiment 1, and difference is:

[0043] (1) Preheating temperature 920°C, time t1=0.4h=20min;

[0044] (2) Recrystallization treatment temperature 1010°C, time t2=0.8h=40min;

[0045] (3) The recrystallized plate is heated to 70°C with the furnace for solution treatment; solution treatment time t3 = 0.6h = 30min;

[0046] (4) The microstructure of the high carbon austenitic stainless steel plate after solution treatment is as follows: figure 2 As shown in (d), (e) and (f), the average grain sizes of the surface layer, quarter and core are: 85 μm, 83 μm and 82 μm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com