Glass fiber mesh and PVC compound enhanced film and production method thereof

A technology of glass fiber mesh and PVC film, applied in the field of composite film, can solve problems such as insufficient impact strength, and achieve the effect of super impact resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

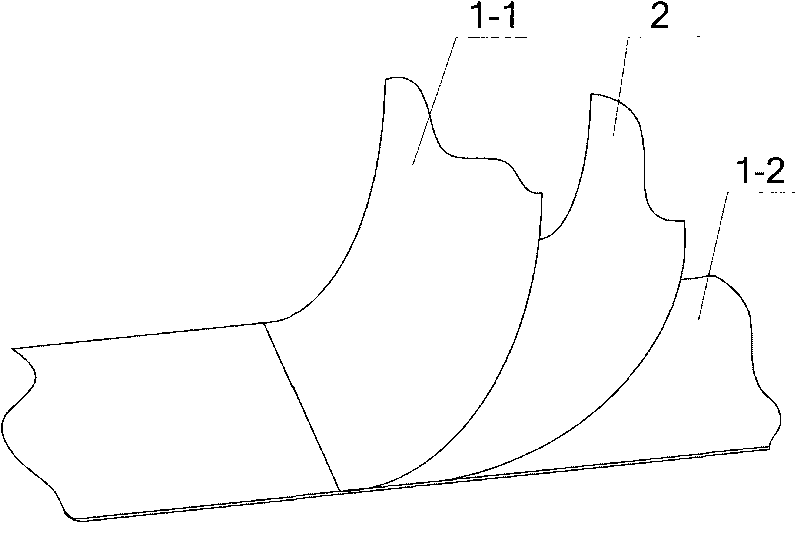

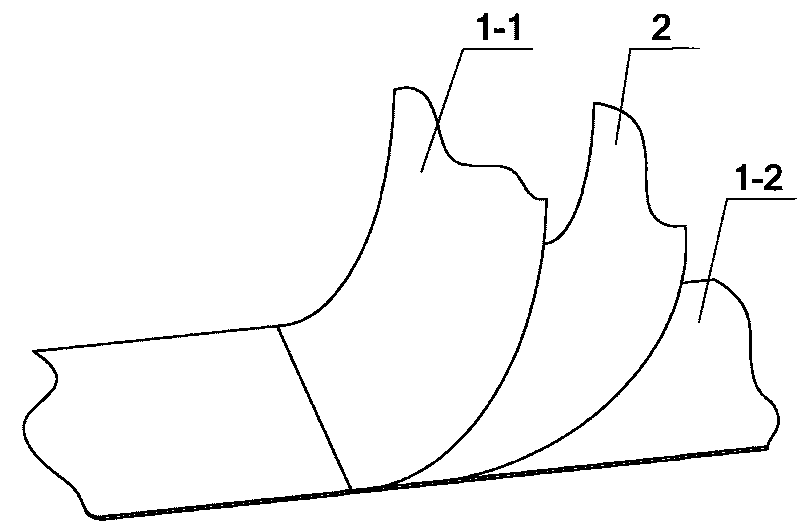

Image

Examples

Embodiment 1

[0027] Step 1. Use a braiding machine to weave high-strength glass fiber filaments into a reticulated glass fiber net.

[0028] Step 2, putting 90 parts by weight of perchlorethylene resin, 40 parts of mixed solvent, 2 parts of tin stabilizer, and 2 parts of calcium stearate into a stirring mixer and fully stirring at 50 ° C, Mix well to form perchlorethylene resin mixture. The mixed solvent is a mixture of di-n-butyl phthalate (DBP) and di-n-octyl phthalate (DOP) with a mass of 1:1; the perchlorethylene resin mixture is put into the solution tank, and the braided The good glass fiber mesh is immersed in the solution tank for 30 seconds through the guide roller, so that it is fully in contact with the perchlorethylene resin mixture; the treated glass fiber mesh is sent to the oven for drying through the guide roller, and the temperature of the oven is controlled at 160 ℃, so that the perchlorethylene resin mixture is covered on the glass fiber mesh; the dried glass fiber mesh...

Embodiment 2

[0031] Step 1. Use a braiding machine to weave high-strength glass fiber filaments into a reticulated glass fiber net.

[0032] Step 2, putting 95 parts by weight of perchlorethylene resin, 50 parts of mixed solvent, 5 parts of tin stabilizer, and 4 parts of calcium stearate into a stirring mixer and fully stirring at 65 ° C, Mix well to form perchlorethylene resin mixture. Wherein the mixed solvent is a mixture of di-n-butyl phthalate (DBP) and di-n-octyl phthalate (DOP) with a mass of 1:2; the perchlorethylene resin mixture is put into the solution tank, and the braided The good glass fiber mesh is immersed in the solution tank for 40 seconds through the guide roller, so that it is fully in contact with the perchlorethylene resin mixture; the treated glass fiber mesh is sent to the oven through the guide roller for drying, and the temperature of the oven is controlled at 180 ℃, so that the perchlorethylene resin mixture is covered on the glass fiber mesh; the dried glass fi...

Embodiment 3

[0035] Step 1. Use a braiding machine to weave high-strength glass fiber filaments into a reticulated glass fiber net.

[0036] Step 2, putting 100 parts by weight of perchlorethylene resin, 70 parts of mixed solvent, 10 parts of tin stabilizer, and 7 parts of calcium stearate into a stirring mixer and fully stirring at 80 ° C, Mix well to form perchlorethylene resin mixture. Wherein the mixed solvent is a mixture of di-n-butyl phthalate (DBP) and di-n-octyl phthalate (DOP) with a mass of 1:1.5; the perchlorethylene resin mixture is put into the solution tank, and the braided The good glass fiber mesh is immersed in the solution tank for 60 seconds through the guide roller, so that it is fully in contact with the perchlorethylene resin mixture; the treated glass fiber mesh is sent to the oven through the guide roller for drying, and the temperature of the oven is controlled at 200 ℃, so that the perchlorethylene resin mixture is covered on the glass fiber mesh; the dried glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com