Method for deeply removing molybdenum from tungstate solution through ion exchange process

An ion exchange method and tungstate technology, which is applied in the field of deep molybdenum removal from tungstate solution by ion exchange method, can solve the problems of short service life, complicated process and high cost of resin, and achieve extended service life, simple operation, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

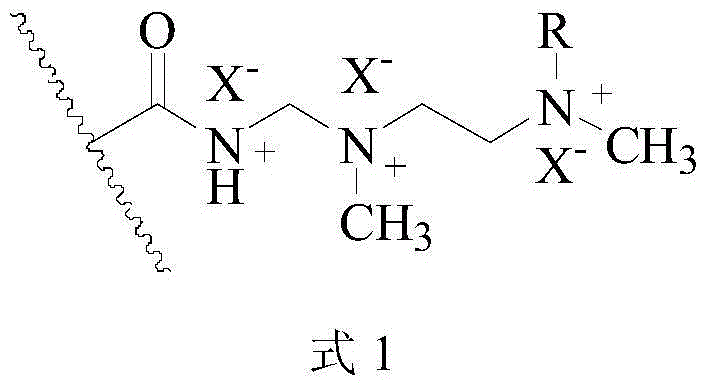

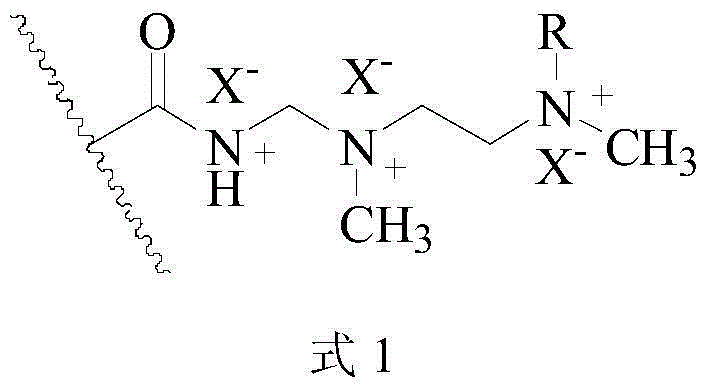

Method used

Image

Examples

Embodiment 1

[0022] Thioated molybdenum-containing sodium tungstate solution containing WO 3 249.65g / L, containing Mo 3.98g / L, flowing through the ion exchange column filled with polyamine-based weakly basic anion resin, when the processing capacity of the feed liquid is 12 times the volume of the resin bed, the Mo content in the effluent is 0.0069 g / L, Mo / WO 3 The mass ratio is 2.76×10 -5 ; Negative molybdenum resin is desorbed with 0.5mol / L NaOH solution. When the amount of desorbent is 6 times of the resin bed volume, the molybdenum desorption rate reaches over 99%.

Embodiment 2

[0024] The desorbed resin in Example 1 is directly used for another batch of molybdenum-containing sodium tungstate solution ion exchange through thiolation to remove molybdenum, and the solution contains WO 3 210.52g / L, containing Mo 14.92g / L, when the feed liquid treatment capacity is 6 times the volume of the resin bed, the effluent contains Mo 0.0091g / L, Mo / WO 3 The mass ratio is 4.32×10 -5 ; Negative molybdenum resin is desorbed with 0.5mol / L NaOH solution. When the amount of desorbent is 6 times the volume of the resin bed, molybdenum desorption is complete.

Embodiment 3

[0026] Thioated molybdenum-containing ammonium tungstate solution containing WO 3 192.46g / L, containing 5.21g / L molybdenum, flowing through the ion exchange column filled with polyamine-based weakly basic anion resin, when the processing capacity of the feed liquid is 10 times the volume of the resin bed, the effluent contains Mo 0.006 g / L, Mo / WO 3 The mass ratio is 3.12×10 -5 ; Negative molybdenum resin is desorbed with 0.5mol / L NaOH solution. When the amount of desorbent is 6 times of the resin bed volume, the molybdenum desorption rate reaches over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com