Device for treating waste water with microwave electrodeless excimer lamp and gas distributing system for lamp

An excimer lamp, a technology for treating wastewater, applied in the direction of light water/sewage treatment, etc., can solve the problems of complex structure, increased volume, filling, etc., and achieve the effects of high vacuum degree, high removal rate, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

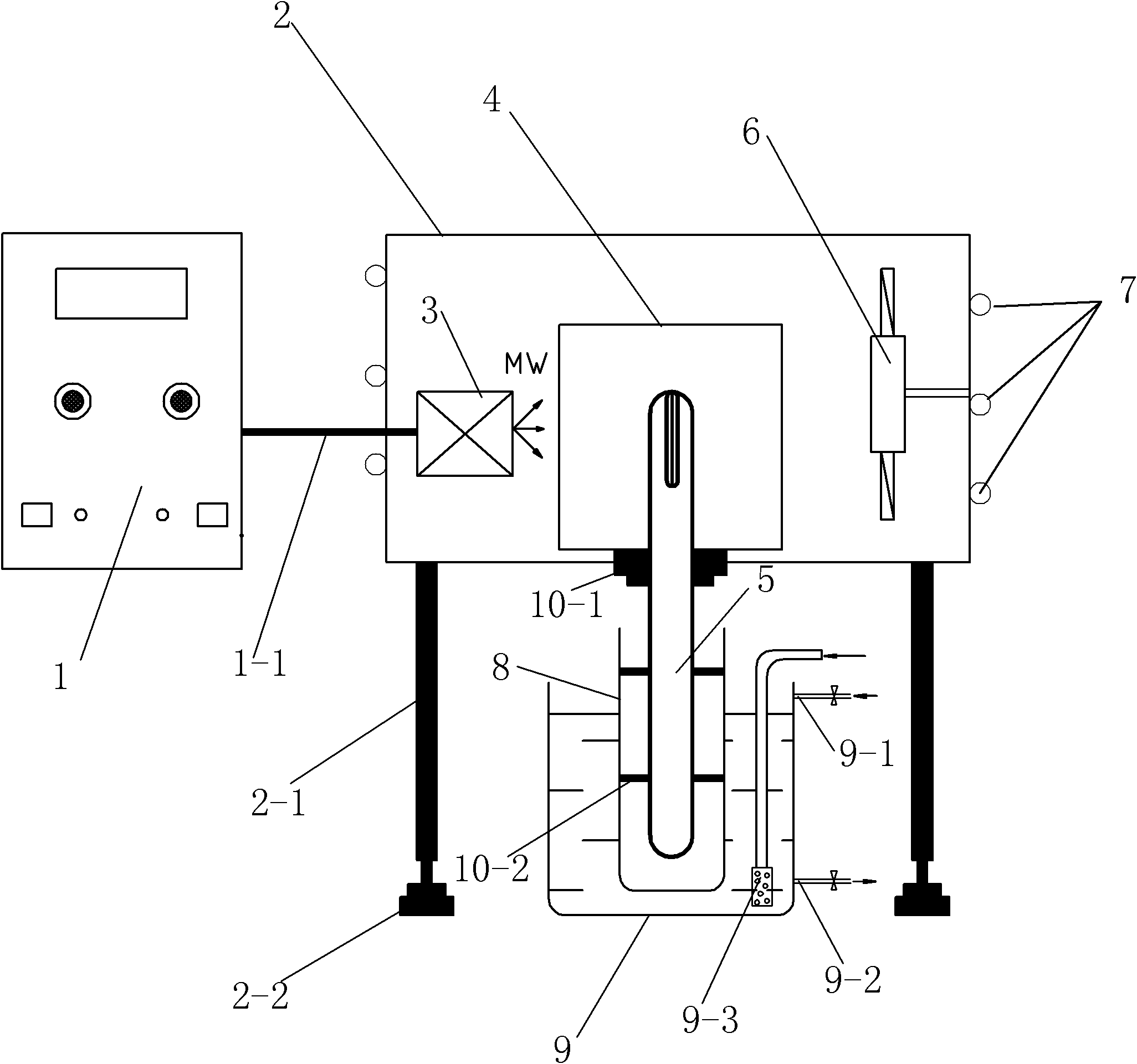

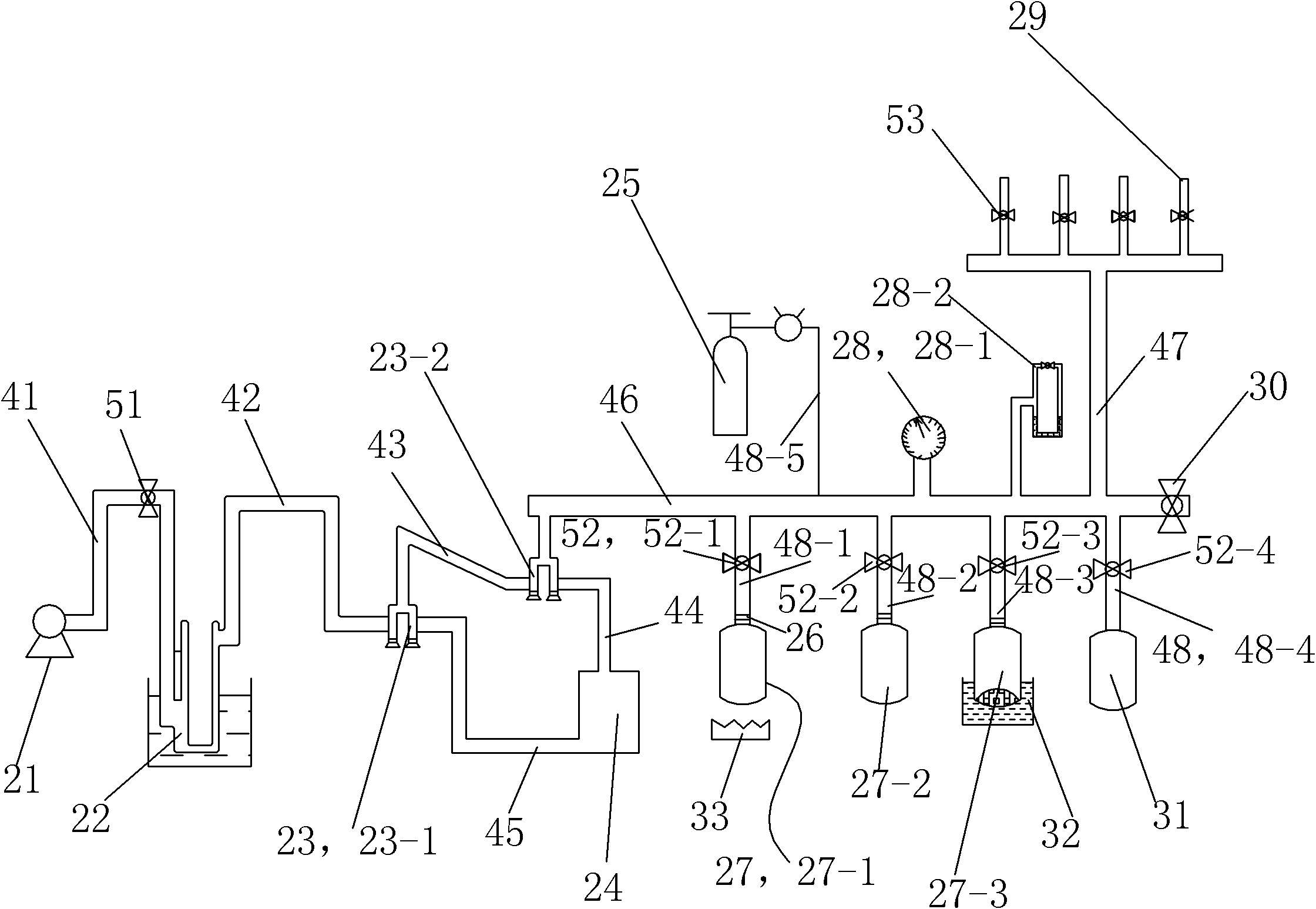

[0024] (the gas distribution system of embodiment 1, electrodeless excimer lamp) see figure 2 , the gas distribution system of the electrodeless excimer lamp of the present embodiment includes a vacuum pump 21, a cold well 22, a three-way valve 23, a diffusion pump 24, a gas washing bottle 25, a gas storage bottle 27, a pressure indicator 28, an inflation pipe 29, an exhaust Gas valve 30, buffer bottle 31 and the corresponding pipelines, valves and pistons connecting the above-mentioned parts; wherein the cold well 22 is a special pipeline placed in the liquid nitrogen tank; the pipelines used for connection are all glass pipe fittings, and the pistons are all It is an oil-free piston, and the piston used in the valve is also an oil-free piston; the gas distribution system also includes a liquid nitrogen tank 32 for cooling the gas cylinder 27 and a heater 33 for heating the gas cylinder 27.

[0025] still see figure 2 , the three-way valve 23 includes a first three-way val...

Embodiment 2

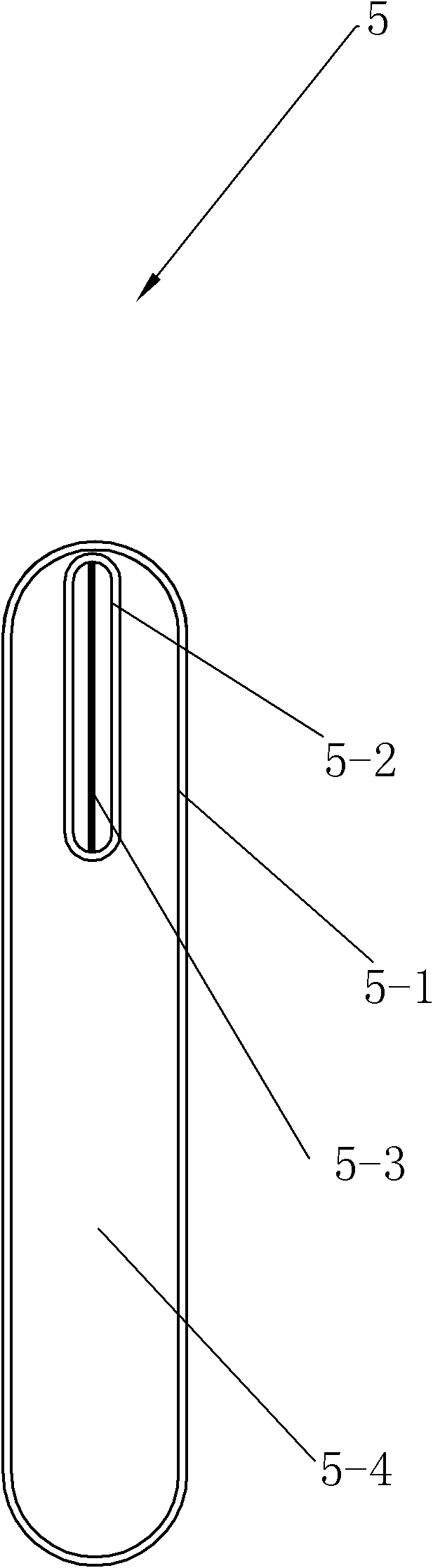

[0040] (Embodiment 2, the gas distribution system of the electrodeless excimer lamp) see image 3 and see figure 2 , the goal of this embodiment is to make the lamp tube 5-1 of the electrodeless excimer lamp 5 filled with krypton gas of 2 torr and bromine vapor of 0.5 torr.

[0041] The rest of the gas distribution system of the electrodeless excimer lamp of this embodiment is basically the same as that of Embodiment 1, the difference is that in the gas storage bottle 27 used, the halogen gas storage bottle 27-1 is a bromine water bottle.

[0042]The rest of the gas distribution method is basically the same as the steps of the gas distribution method in Embodiment 1, the difference is that in step ①, when connecting the gas storage cylinder 27, keep the air inlet of the first branch pipeline 48-1 The closed state remains unchanged, and the air inlet of the second branch pipeline 48-2 is still changed from a closed state to a state of sintering communication with the gas outl...

Embodiment 3

[0044] (Embodiment 3, the gas distribution system of the electrodeless excimer lamp) The goal of this embodiment is to make the electrodeless excimer lamp 5 of the argon gas of 0.2torr and the mercury vapor of 0.5torr that the filling gas 5-4 that fills in is made Lamp 5-1.

[0045] The rest of the gas distribution system of the electrodeless excimer lamp of the present embodiment is basically the same as that of Embodiment 1, the difference is that when selecting the gas storage cylinder 27, the halogen gas storage cylinder 27-1 is not used, and the inert gas storage cylinder is adopted 27-2 and mercury cylinder 27-3. The used inert gas storage cylinder 27-2 is an argon cylinder; the mercury storage cylinder 27-3 is also called a mercury cylinder.

[0046] The rest of the gas distribution method is basically the same as the steps of the gas distribution method in Embodiment 1, the difference is that in step ①, when connecting the gas storage cylinder 27, keep the air inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com