All-in-one machine for rolling, laminating and lithium-supplementing

An all-in-one, lithium-supplementing technology, which is applied in electrode manufacturing, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problems of battery cycle life reduction and achieve the effect of compact structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

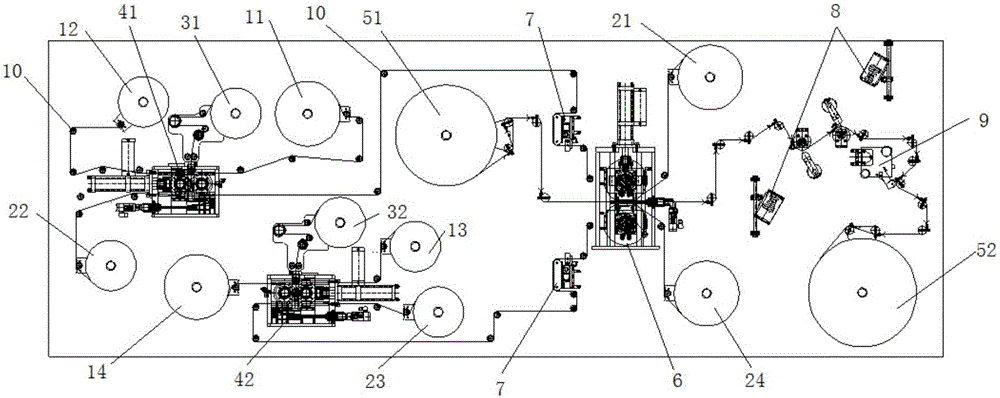

[0021] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

[0022] refer to figure 1 , an all-in-one machine for calendering and coating lithium supplementation, comprising a first calendering device 41, a second calendering device 42, a first lithium ribbon unwinding device 31, a second lithium ribbon unwinding device 32, a coating device 6, a first isolation Film unwinding device 11, first separator rewinding device 21, second separator unwinding device 12, second separator rewinding device 22, third separator unwinding device 13, third separator rewinding device 23. The fourth separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com