Industrializable waste thermosetting plastic regeneration process and equipment based on mechanical and physical method

A thermosetting and physical method technology, applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problems of large decline in mechanical properties of products, difficulties in reusing and recycling, and difficulty in recycling, etc., to achieve recycled materials. High utilization rate and utilization value, no secondary pollution, and the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In Example 1, waste and old thermosetting phenolic laminated plastics are taken as an example:

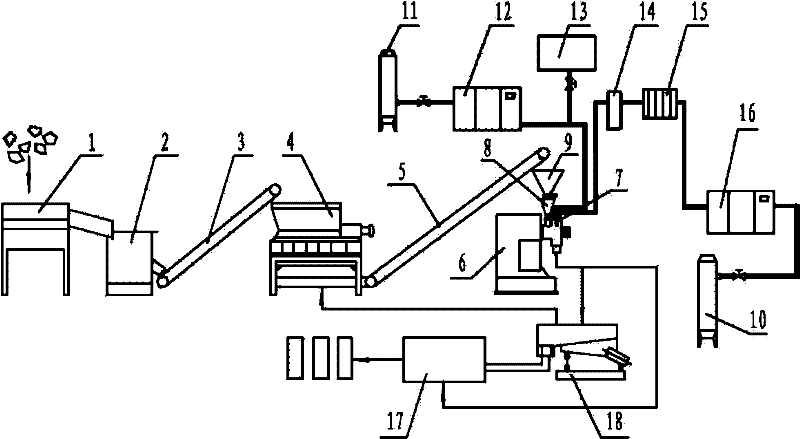

[0071] Firstly, waste and old thermosetting phenolic laminated plastics are cleaned and dried by a washing machine 1 and a dryer 2, and then transported to a crusher 4 by a first-stage conveyor belt 3 to be broken into lumps, and the lumps are sent by a second-stage conveyor belt 5 Transported to the raw material bin 9 of the regeneration device 6, the material is dropped into the regeneration device 6 by the raw material bin 9 through the lower hopper 8;

[0072] Close the feeding port on the lower hopper 8, open the gas valve of the nitrogen cylinder 11, nitrogen enters the cavity of the regeneration device 6 through the gas compressor 12 through the pipeline, and open the gas valve of the steam generator 13 at the same time, and the water vapor is introduced through the pipeline In the cavity of regeneration device 6, utilize temperature sensor 7 to display the temperatur...

Embodiment 2

[0078] Present embodiment 2 is an example with waste and old thermosetting rigid polyurethane plastics:

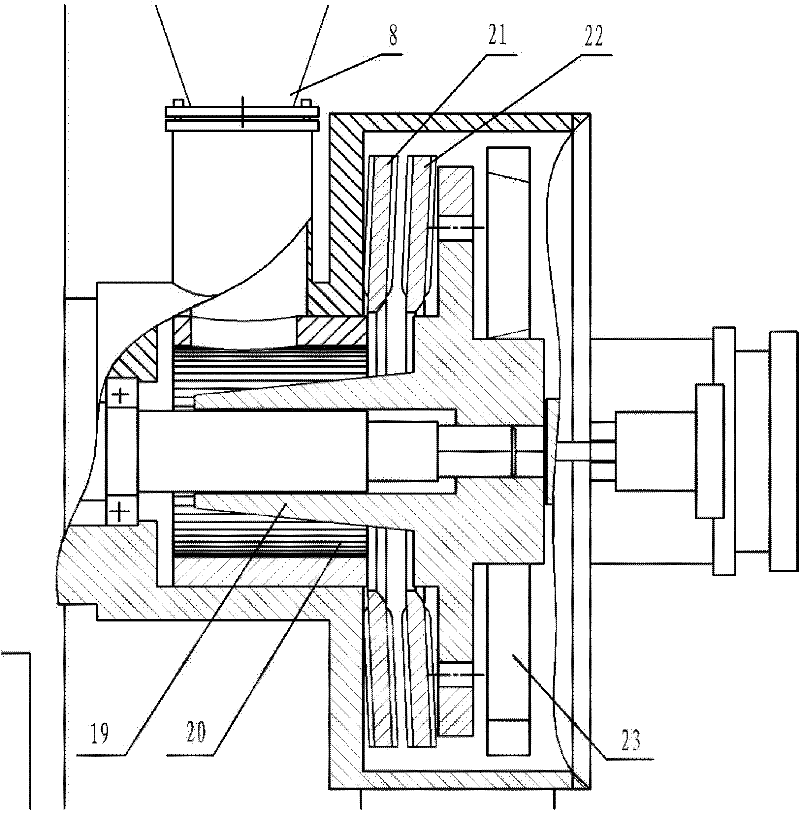

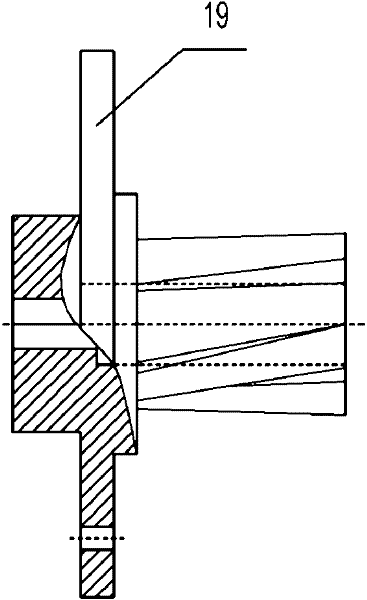

[0079] The regeneration process is the same as in Example 1, wherein the rotating speed of the shearing knife shaft 19 is 2000n / min, and the time to complete the degradation is 70 minutes. Due to the low strength of the thermosetting hard polyurethane plastic, the static grinding disc and the moving grinding disc can be selected from the grinding teeth to form an arc. In the form of a linear grinding disc, in this example, isocyanate and water are added to the raw material bin 9 to enhance the regeneration effect, and the degradation and regeneration products of waste thermosetting polyurethane are directly subjected to compression molding in the mold without vibration screening.

[0080] The experimental results show that: after pulverization and regeneration of thermosetting rigid polyurethane plastics, through the microstructure characterization test, the polymer network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com