High-capacity ultrasonic crushing and dispersing device

An ultrasonic crushing and large-capacity technology, which is applied in the direction of mixer accessories, mixers, dissolution, etc., can solve problems such as easy to exceed, the emission area should not be too large, and transducer damage, etc., to achieve expanded use range, convenient operation, and uniformity increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

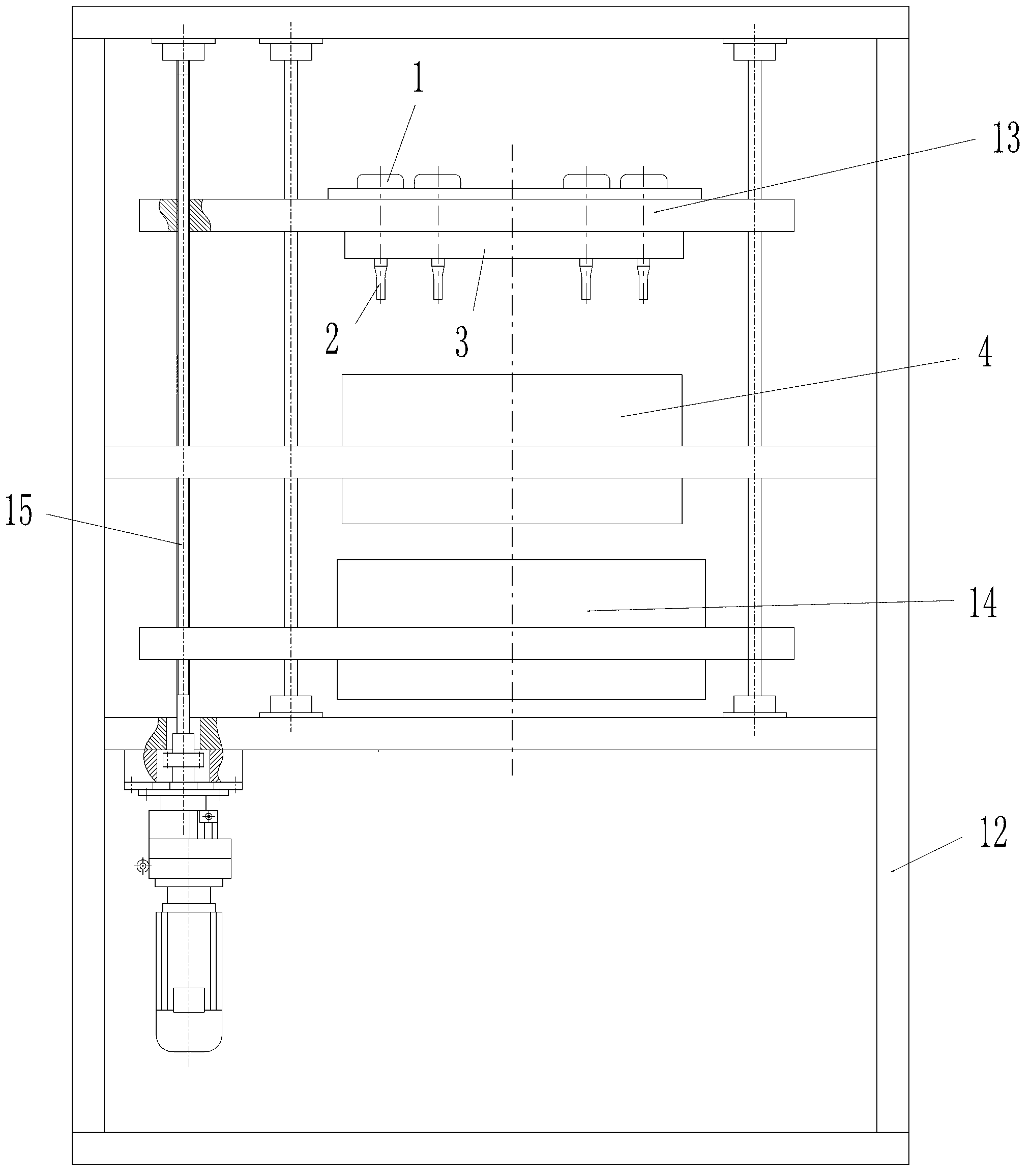

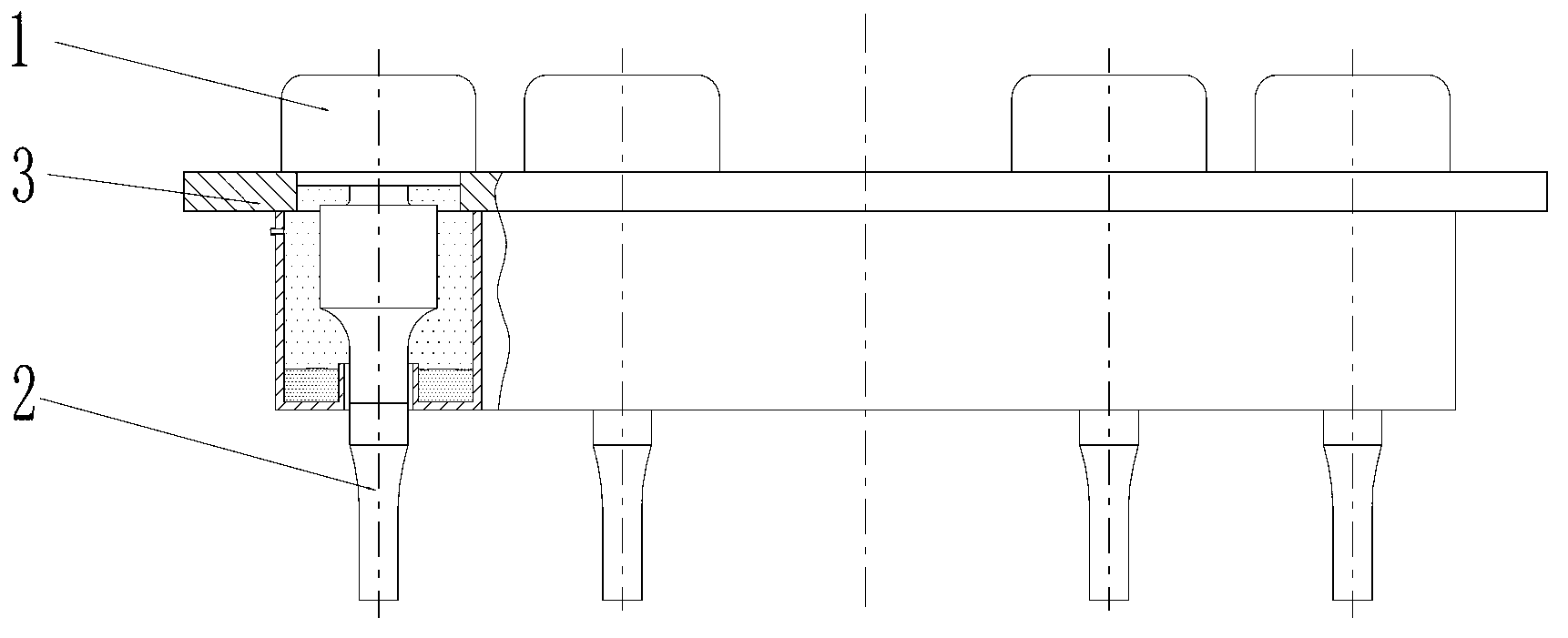

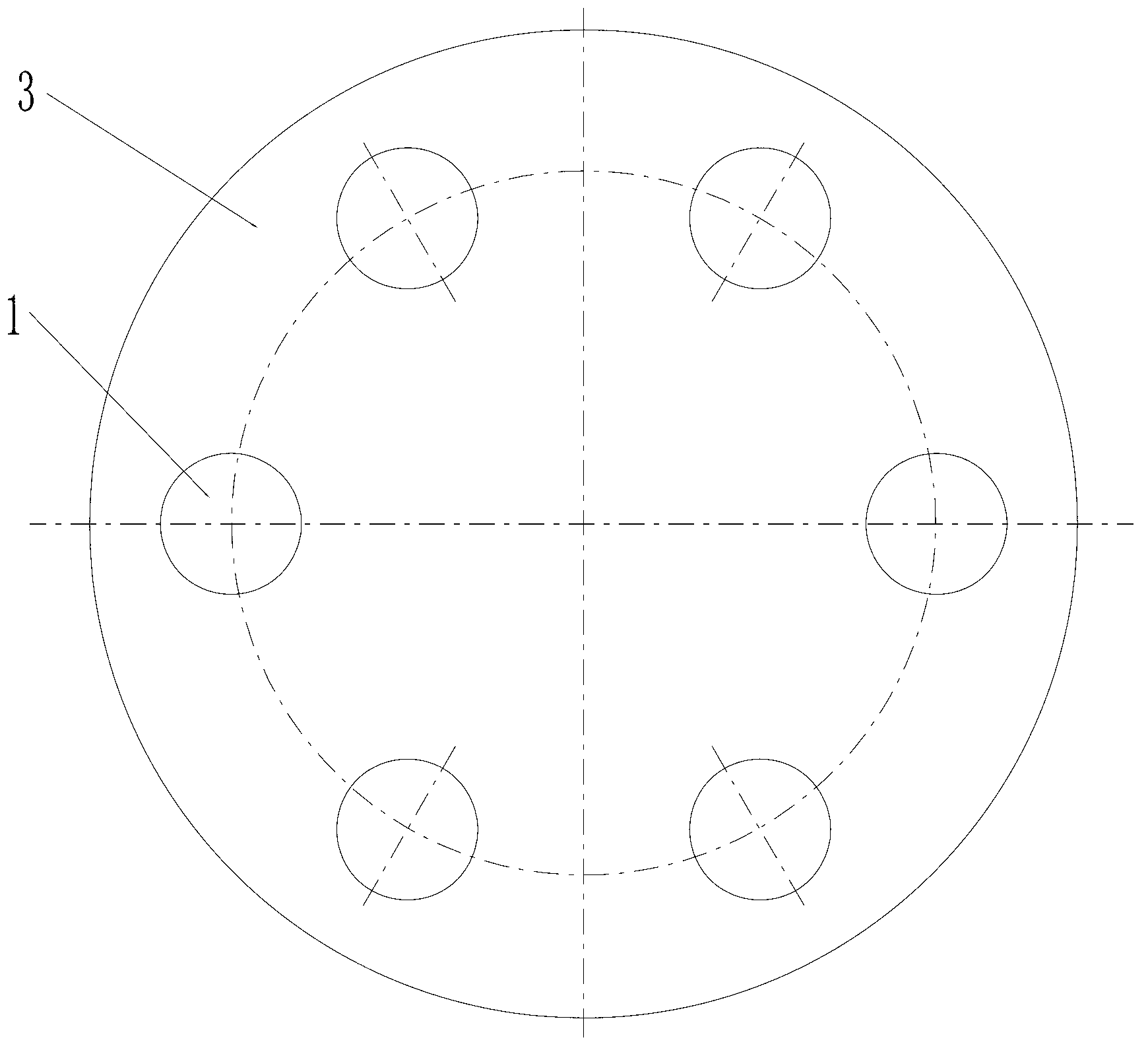

[0029] A large-capacity ultrasonic crushing and dispersing device of the present invention, such as figure 1 As shown, it is mainly composed of an ultrasonic device 13, a material container 4, a magnetic stirring device 14, an automatic lifting device 15, and a frame 12. Among them, such as Figure 4 As shown, the ultrasonic device 13 includes an ultrasonic transducer 1, an ultrasonic horn 2 and a transducer cooling sleeve 3, and the ultrasonic horn 2 is coaxial with the ultrasonic transducer 1 and is installed on the lower end of the ultrasonic transducer 1 , the transducer cooling sleeve 3 is a hollow annular cylinder, the ultrasonic transducer 1 is installed on the transducer cooling sleeve 3 and its vibrating element penetrates the inner cavity of the transducer cooling sleeve 3, and multiple ultrasonic transducers 1 Installed on the transducer cooling sleeve 3 and evenly distributed, such as figure 2 As shown, there is a small gap between the vibrating element and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com