Surface oxidation modification process for waste tire rubber powder for modification of asphalt

A technology of asphalt modification and surface oxidation, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility, limit the transportation radius and storage time of modified asphalt, and achieve better wetting performance and easy industrialization Effect of application and improvement of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

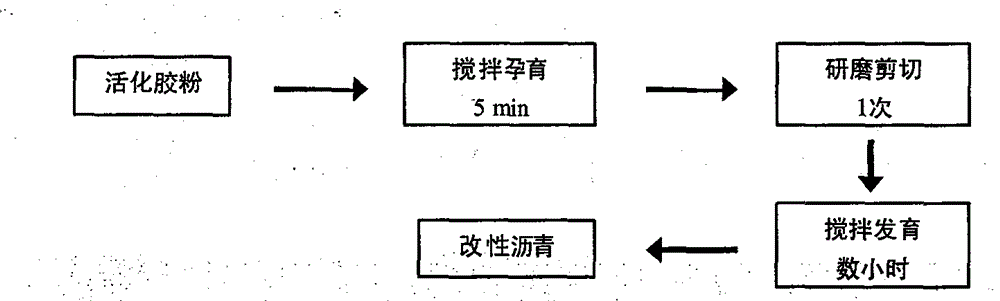

Method used

Image

Examples

Embodiment 1

[0019] Take 200g waste tire rubber powder and 10g (5wt%) sodium dichloroisocyanurate and disperse in 600mL water. After stirring at a constant temperature of 25°C for 1.5 hours, the waste tire rubber powder was filtered, washed, and dried at 60°C until the quality was constant to obtain modified rubber powder. Modified rubber powder and No. 70 road asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. The 25°C penetration, 5°C ductility and softening point of the modified asphalt were tested. Among them, the penetration at 25°C is 36, the ductility at 5°C is 6.8, and the softening point is 74.3. The unmodified No. 70 road asphalt has a penetration of 43 at 25°C, a ductility of 8.1 at 5°C, and a softening point of 63.3. It can be seen that the penetration at 25°C and the ductility at 5°C are significantly reduced, and the softening point is significantly increased.

Embodiment 2

[0021] Take 200g waste tire rubber powder and 60g (30wt%) sodium dichloroisocyanurate and disperse in 600mL water. After stirring at a constant temperature of 25°C for 1.5 hours, the waste tire rubber powder was filtered, washed, and dried at 60°C until the quality was constant to obtain modified rubber powder. Modified rubber powder and No. 70 road asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. The 25°C penetration, 5°C ductility and softening point of the modified asphalt were tested. Among them, the penetration at 25°C is 35, the ductility at 5°C is 4, and the softening point is 66.3. The unmodified No. 70 road asphalt has a penetration of 43 at 25°C, a ductility of 8.1 at 5°C, and a softening point of 63.3. It can be seen that the penetration at 25°C and the ductility at 5°C are significantly reduced, and the softening point is increased.

Embodiment 3

[0023] Take 200g waste tire rubber powder and 20g (10wt%) trichloroisocyanuric acid and disperse in 600mL water. After stirring at a constant temperature of 25°C for 1.5 hours, the waste tire rubber powder was filtered, washed, and dried at 60°C until the quality was constant to obtain modified rubber powder. Modified rubber powder and No. 70 road asphalt were prepared by wet modification process, and the mixing amount of waste tire rubber powder was 21wt%. The 25°C penetration, 5°C ductility and softening point of the modified asphalt were tested. Among them, the penetration at 25°C is 27, the ductility at 5°C is 2, and the softening point is 71. The unmodified No. 70 road asphalt has a penetration of 43 at 25°C, a ductility of 8.1 at 5°C, and a softening point of 63.3. It can be seen that the penetration at 25°C and the ductility at 5°C are significantly reduced, and the softening point is significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com