6-8mm TMCP on-line quenching low-yield-ratio high-strength wear-resistant steel NM400 coiled plate and production method thereof

A technology of low yield ratio and wear-resistant steel, applied in the field of wear-resistant steel, can solve the problems of high alloy cost and high content of Ti element, and achieve the effect of short manufacturing process, low yield ratio, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

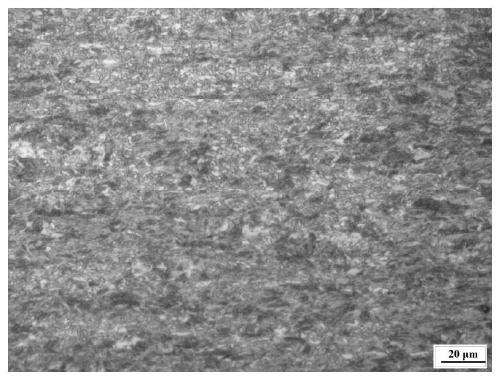

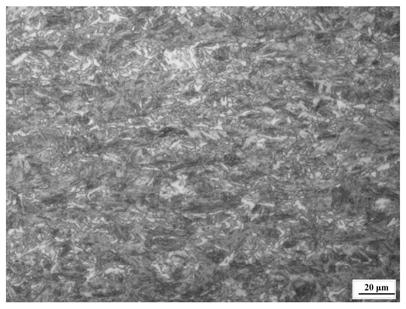

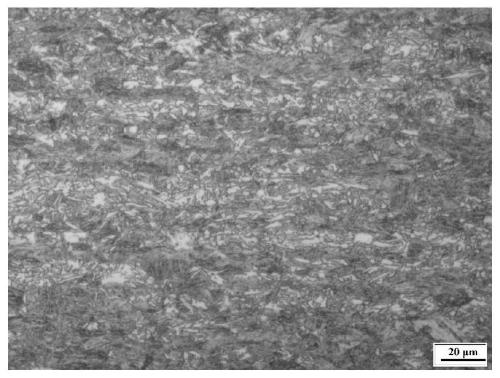

[0035]As shown in Table 1 below, the chemical composition of the coils is shown. The slab heating temperature is 1200°C and the heating time is 130min. The rough rolling adopts R1 and R2 for 3+5 passes, and the thickness of the middle billet is 42mm; The method is two-stage cooling, the front stage is encrypted and rapidly cooled to 610°C, the air cooling time is 8s, and the coiling temperature is 100°C, and the coiled plate can be obtained. Such as figure 1 As shown, the metallographic structure of the coil is shown, which is a two-phase structure of ferrite + martensite, the grain structure is evenly distributed, and there is no mixed crystal and segregation.

Embodiment 2

[0037] As shown in Table 1 below, the chemical composition of the coils is shown. The slab heating temperature is 1210°C and the heating time is 125min. Rough rolling is carried out by R1 and R2 for 3+5 passes. The thickness of the intermediate billet is 44mm; The method is two-stage cooling, the front stage is encrypted and rapidly cooled to 625°C, the air cooling time is 9s, and the coiling temperature is 130°C to obtain the coiled plate. Such as figure 1 As shown, the metallographic structure of the coil is shown, which is a two-phase structure of ferrite + martensite, the grain structure is evenly distributed, and there is no mixed crystal and segregation.

Embodiment 3

[0039] As shown in Table 1 below, the chemical composition of the coils is shown. The slab heating temperature is 1220°C, and the heating time is 135 minutes. The rough rolling adopts R1 and R2 for 3+5 passes, and the thickness of the middle billet is 46mm; The method is two-stage cooling, the front stage is encrypted and rapidly cooled to 620°C, the air cooling time is 10s, and the coiling temperature is 155°C, so that the coil can be obtained. Such as figure 1 As shown, the metallographic structure of the coil is shown, which is a two-phase structure of ferrite + martensite, the grain structure is evenly distributed, and there is no mixed crystal and segregation.

[0040] Table 1: Embodiment 1~3 chemical composition (wt%)

[0041] Example C Si mn P S als Cr Nb Ti B Ca H O N 1 0.20 0.38 1.40 0.010 0.002 0.030 0.35 0.022 0.015 0.0012 0.0020 0.00010 0.0016 0.0032 2 0.19 0.42 1.35 0.008 0.002 0.035 0.33 0.020 0.018 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com