Device and method for controlling gas density distribution on magnetron sputtering cathode surface

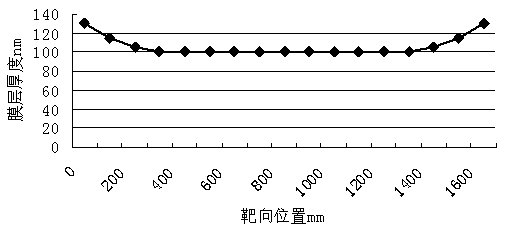

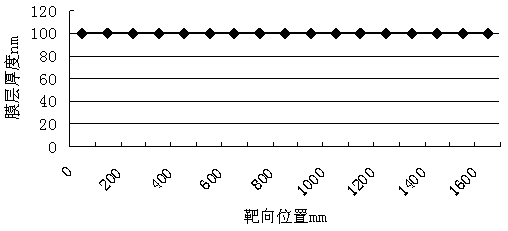

A cathode surface and gas density technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of poor film thickness uniformity, large difference, sputtering deposition rate difference, etc., and achieve gas The effect of uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

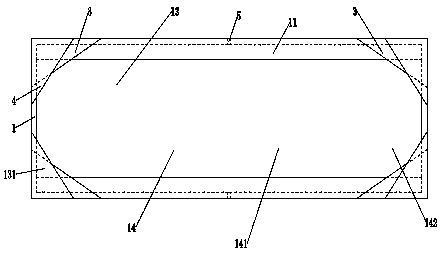

[0015] see image 3 , 4 In the shown flexible and continuous magnetron sputtering cathode surface gas density distribution control device, the shield 1 includes a panel 11 and a peripheral plate 12 , and the cathode target 2 is located in the shield 1 . A working (reaction) gas injection port 5 is opened on the peripheral plate 12 .

[0016] A rectangular hole 13 is provided on the shielding cover panel, and two baffle plates 3, 4 are stacked in turn on the four inner corners of the rectangular hole 13 on the upper part of the panel, and the two baffle plates 3, 4 at each inner corner have blocked each inner corner. In this way, the oblong hole 13 forms the waist-shaped sputtering hole 14 except the four inner corners 131 that are blocked by the shielding plate. The length direction of the waist-shaped sputtering hole is consistent with the length direction of the cathode target. The two ends of the waist-shaped sputter hole are broken lines composed of five line segments....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com