Method for preparing carbon nanomaterial by using high temperature solid oxide fuel cell

A technology of solid oxide and nano-carbon materials, applied in fuel cells, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high cost and complicated process, and achieve low preparation cost and simple process , the effect of easy gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

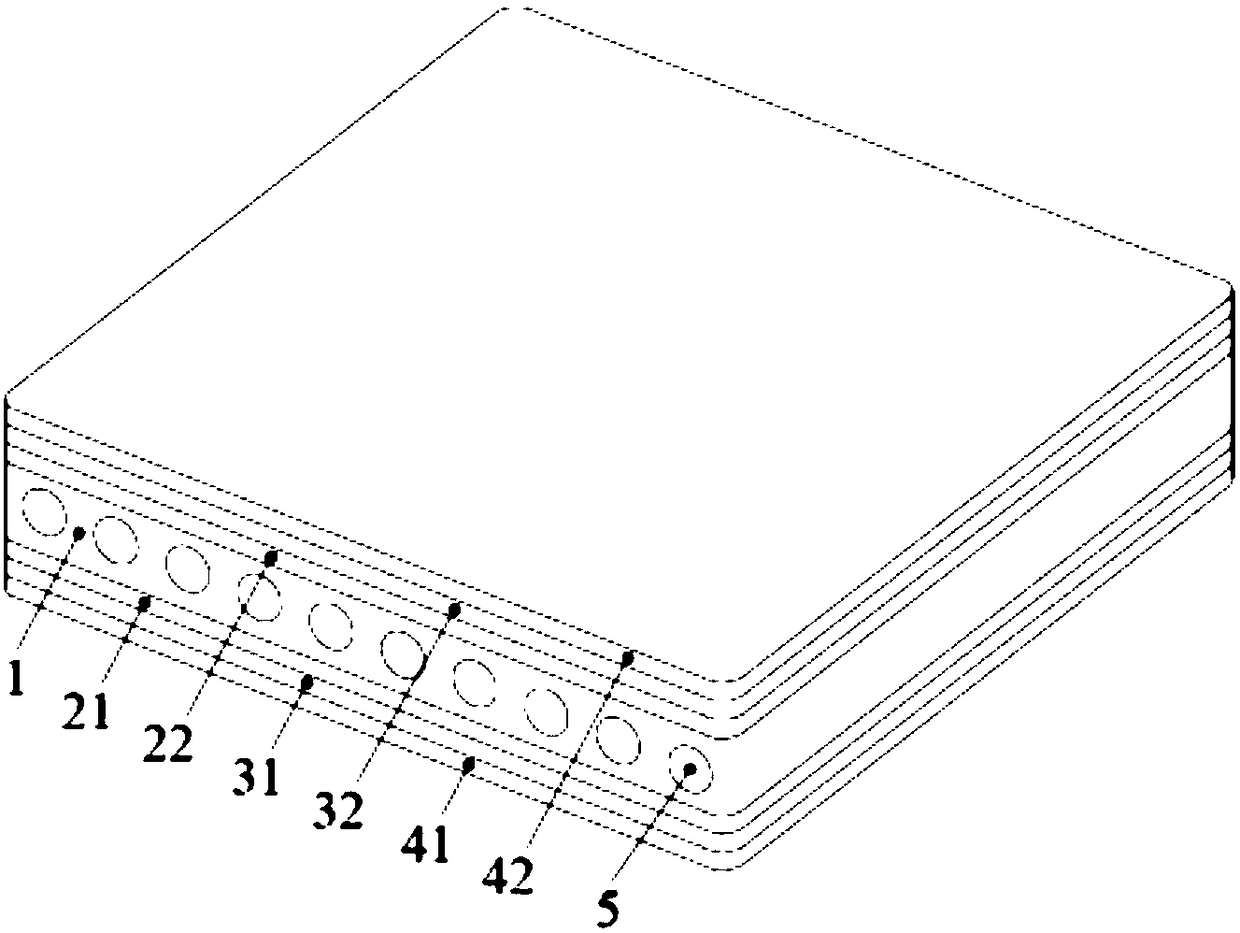

[0026] In this embodiment, the schematic diagram of the SOFC battery structure is a ceramic electrolyte battery supported by flat-plate electrodes, and its structure is as figure 1 As shown, the anode support layer 1, the electrolyte layer, and the cathode layer are stacked up and down in the thickness direction. The electrolyte layer includes a first electrolyte layer 22 and a second electrolyte layer 21. The first electrolyte layer 22 is located on the upper surface of the anode support layer 1, and the second electrolyte layer 21 is located on the lower surface of the anode support layer 1. The first barrier layer 32 is located on the upper surface of the first electrolyte layer 22, and the second barrier layer 31 is located on the lower surface of the second electrolyte layer 21. The cathode layer includes an upper first cathode layer 42 and a second cathode layer 41. The first cathode layer 42 is located on the upper surface of the first barrier layer, and the second cathod...

Embodiment 2

[0049] In this embodiment, the structure of the SOFC cell and the preparation method thereof are completely the same as those in the first embodiment.

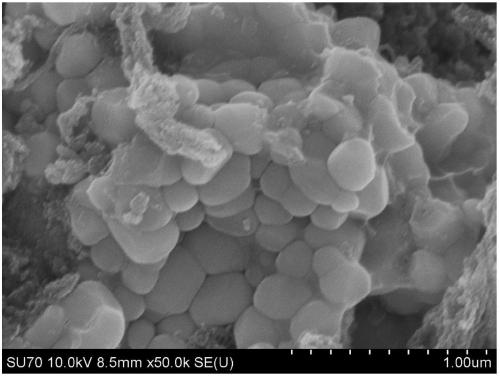

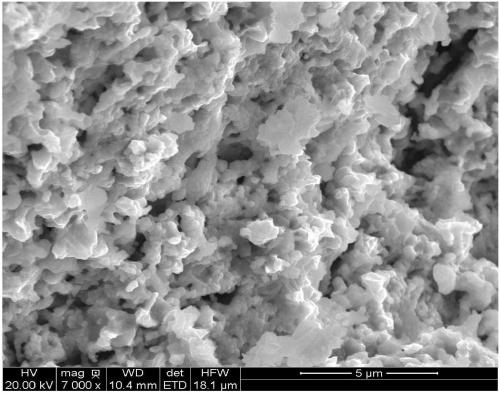

[0050] When the SOFC battery is in working condition, pass ethanol, carbon monoxide and water with a molar ratio of 4:3:2 into the pores, and electrochemically react with oxygen ions in the three-phase regions on the upper and lower sides of the anode support layer, and at the same time in the Ni base Carbon deposition occurs on the anode layer substrate. Through the effect of different battery current densities, the size of the oxygen ion current can be controlled, thereby controlling the deposition rate of carbon to obtain the desired form of carbon deposition. When the control battery current density is 0.2A / cm 2 , The SEM image of the obtained carbon material is similar figure 2 As shown, the particle size of the carbon material is on the order of nanometers, and the carbon particles are more uniformly precipitated on the an...

Embodiment 3

[0052] In this embodiment, the structure of the SOFC cell and the preparation method thereof are completely the same as those in the first embodiment.

[0053] When the SOFC battery is in working condition, pass ethanol, carbon monoxide, and water in a molar ratio of 5:4:3 into the pores, and electrochemically react with oxygen ions in the three-phase regions on the upper and lower sides of the anode support layer, and at the same time in the Ni base Carbon deposition occurs on the anode layer substrate. Through the effect of different battery current densities, the size of the oxygen ion current can be controlled, thereby controlling the deposition rate of carbon to obtain the desired form of carbon deposition. When the control battery current density is 0.5A / cm 2 , The SEM image of the obtained carbon material is similar figure 2 As shown, the particle size of the carbon material is on the order of nanometers, and the carbon particles are more uniformly precipitated on the ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com