Fabricated light protective door and manufacturing method thereof

A manufacturing method and technology of protective doors, which are applied to doors, windows/doors, and anti-war damage, etc., can solve the problems of high maintenance costs, large constraints, and reduced protection reliability of civil air defense facilities, and achieve good operational performance and economic performance. , reduce weight, improve the effect of anti-knock and anti-shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

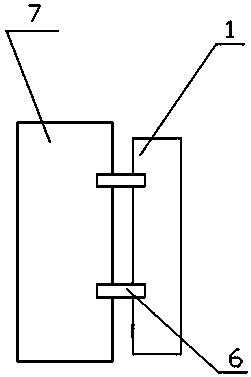

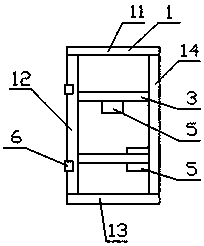

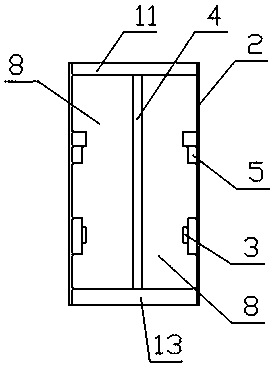

Image

Examples

Embodiment Construction

[0026] The manufacturing method of the assembled lightweight protective door of the present invention comprises the following steps:

[0027] 1) According to the process requirements, make or prepare the door frame components of the protective door (mainly including the four sides of the rectangular frame structure), frame connecting steel components, grids (preferably FRP composite materials), embedded parts, and skins and hinges; the metal frame of the protective door is decomposed to obtain the aforementioned components, and the above-mentioned single components are respectively manufactured and processed in the factory to obtain components that cooperate with each other and have corresponding sizes; the door frame components, frame connecting components, grids, Embedded parts and skins are metal materials or FRP composite materials;

[0028] 2) According to the process requirements, cooperate with the installation site to make the protective door frame wall for installing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com