Bridge pier structure and construction method thereof

A construction method and bridge pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of complex process, construction quality and durability need to be further improved, achieve mature technology, alleviate the impact of urban traffic environment, and shorten the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

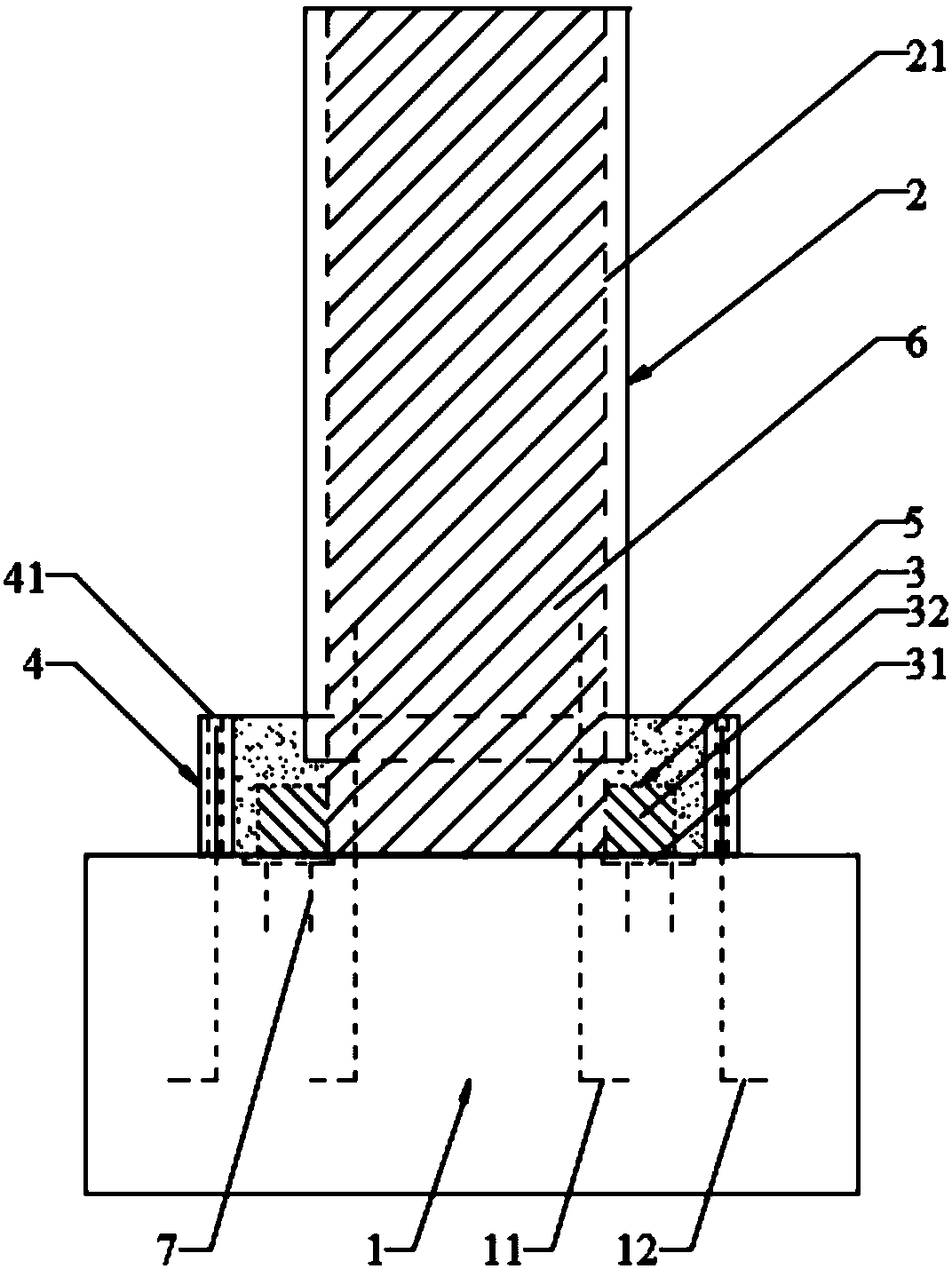

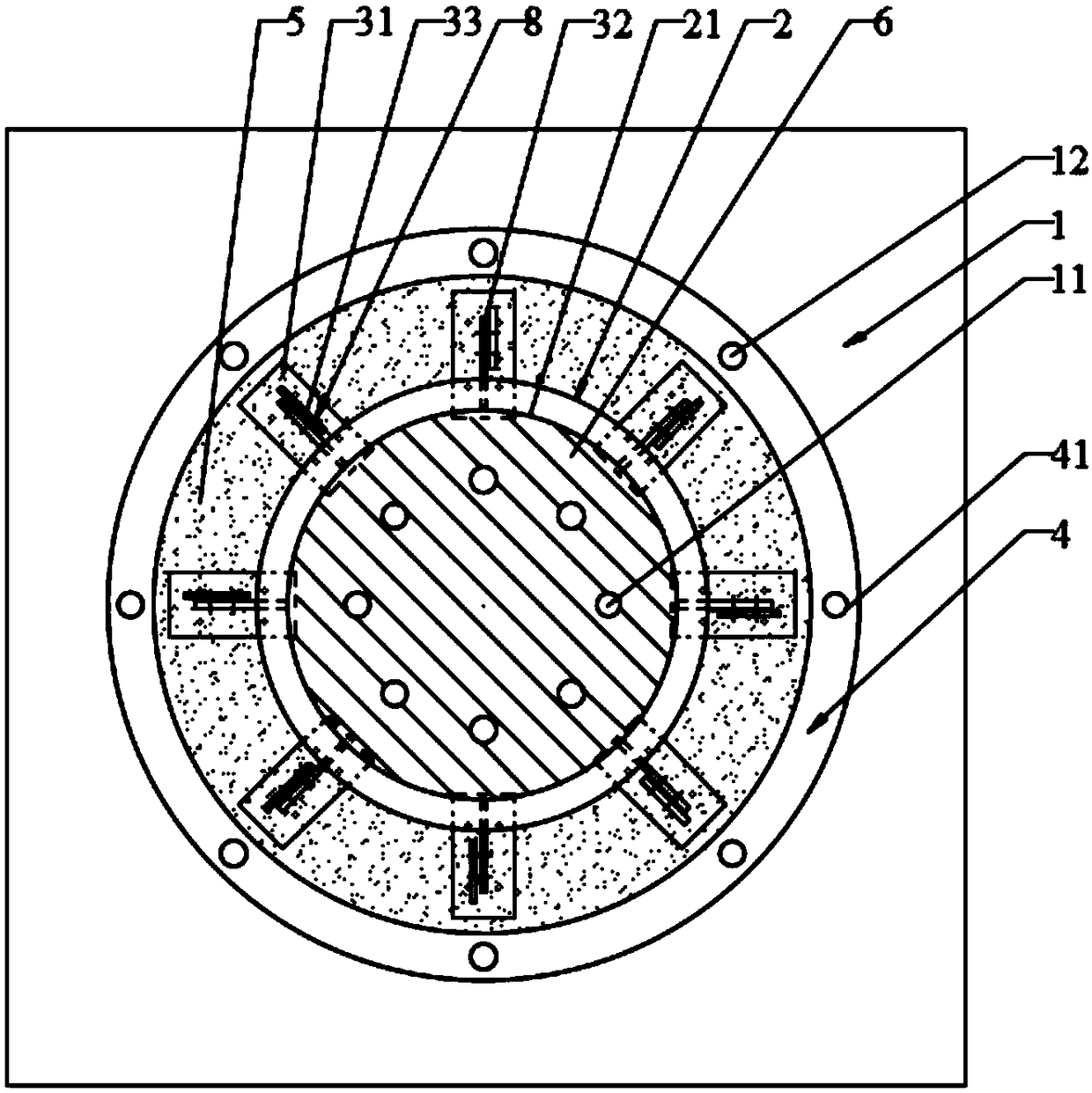

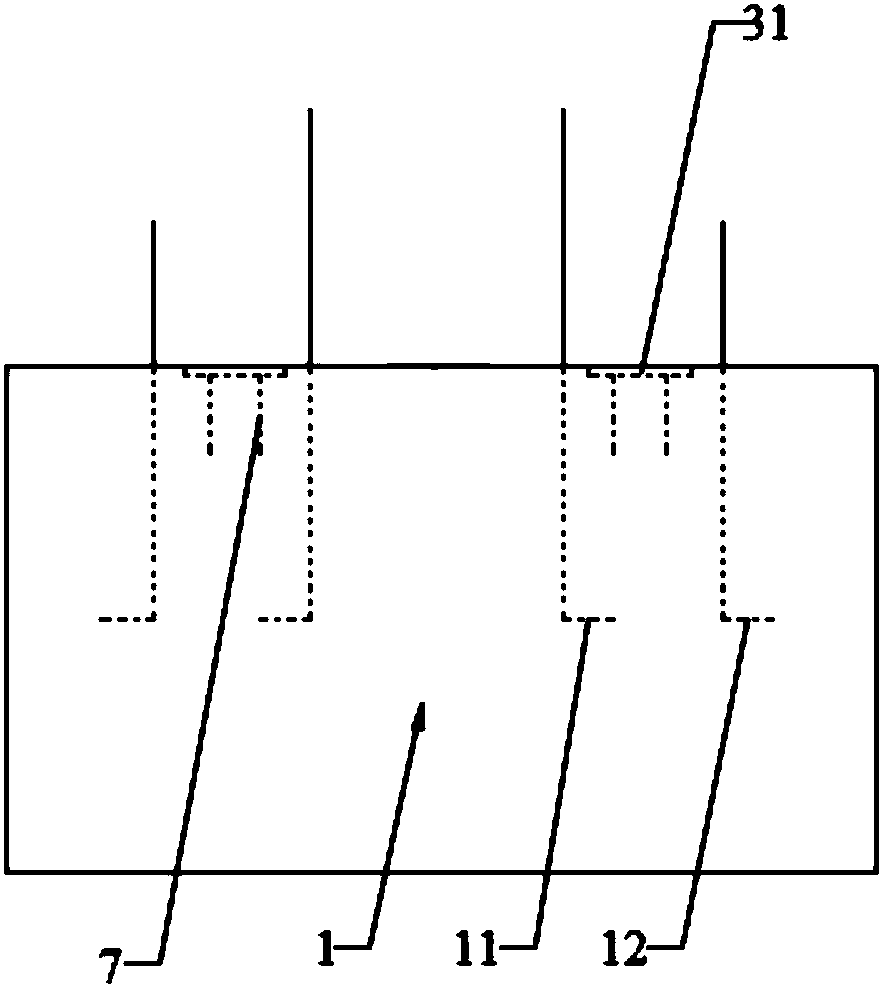

[0073] Please refer to Figure 1 to Figure 8 As shown, a bridge pier structure includes a prefabricated bridge pier 1, a prefabricated bridge pier 2, a steel plate assembly 3 and a thin-walled ring 4; the prefabricated bearing platform 1 is pre-embedded with two groups of vertically arranged and evenly distributed circumferentially. The first steel bar 11 and the second steel bar 12, the first steel bar 11 is located at the inner side of the second steel bar 12, and the top ends of the first steel bar 11 and the second steel bar 12 all protrude from the upper surface of the prefabricated platform 1; The prefabricated pier 2 is pre-embedded with a hollow steel pipe 21 that runs through the prefabricated pier 2 and is arranged in the vertical direction. The prefabricated pier 2 is arranged on the prefabricated platform 1 through the hollow steel pipe 21. The upper surface of the prefabricated pier 2 is flush, and the lower end surface of the hollow steel pipe 21 extends out of t...

Embodiment 2

[0077] It is the same as other structures of a bridge pier structure in Embodiment 1, except that the steel plate assembly 3 includes a first steel plate 31, a second steel plate 32 and a third steel plate 33, and the first steel plate 31 is pre-embedded in the prefabricated platform 1 Inside and between the first steel bar 11 and the second steel bar 12, the first steel plate 31 is horizontally arranged and the upper surface of the first steel plate 31 is flush with the upper surface of the prefabricated platform 1; the second steel plate 32 Vertically arranged and located between the prefabricated pier 2 and the first steel plate 31, one side of the second steel plate 32 is connected to the outer surface of the hollow steel pipe 21, the lower surface of the second steel plate 32 is connected to the upper surface of the first steel plate 31 Surface connection; the third steel plate 33 is vertically connected to the first steel plate 31 and the third steel plate 33 is connected...

Embodiment 3

[0080] Referring to a bridge pier structure in Embodiment 1, the present invention also provides a construction method for a bridge pier structure, comprising the following steps:

[0081] Step 1, fixing the prefabricated platform 1;

[0082] Step 2, passing the pre-embedded second steel bar 12 on the prefabricated cap 1 through the reserved hole 41 on the thin-walled ring 4, and fixing the thin-walled ring 4 on the prefabricated cap 1;

[0083] Step 3, the prefabricated pier 2 is fixed on the prefabricated platform 1 through the steel plate assembly 3, and the first steel bars 11 are all located in the hollow steel pipe 21 at this time;

[0084] Step 4, pouring the first post-cast self-compacting concrete 5 between the thin-walled ring 4 and the prefabricated pier 2;

[0085] Step 5. After the first post-cast self-compacting concrete 5 reaches the strength requirement, pour the second post-cast self-compacting concrete 6 in the hollow steel pipe 21 of the prefabricated pier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com