Carbon-coated silver nanowire

A technology of silver nanowires and carbon packs, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of affecting the reliability of related devices, increasing the complexity of the process, and increasing the cost of preparation. To achieve the effect of preventing silver migration, preventing the oxidation of nano-silver, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Collect sorghum, wash it with water and ethanol in sequence, and dry it overnight in an oven at 45°C;

[0036] (2) Take by weighing 2 mg of silver sulfate, dissolve it in 8 mL of water, stir fully to make it dissolve completely, and prepare a 0.25 mg / mL silver sulfate solution;

[0037] (3) Transfer the silver sulfate solution in step (2) to a 10 mL reaction kettle, add 2 mg of sorghum dried in step (1), seal the reaction kettle, and react at 100° C. for 8 hours;

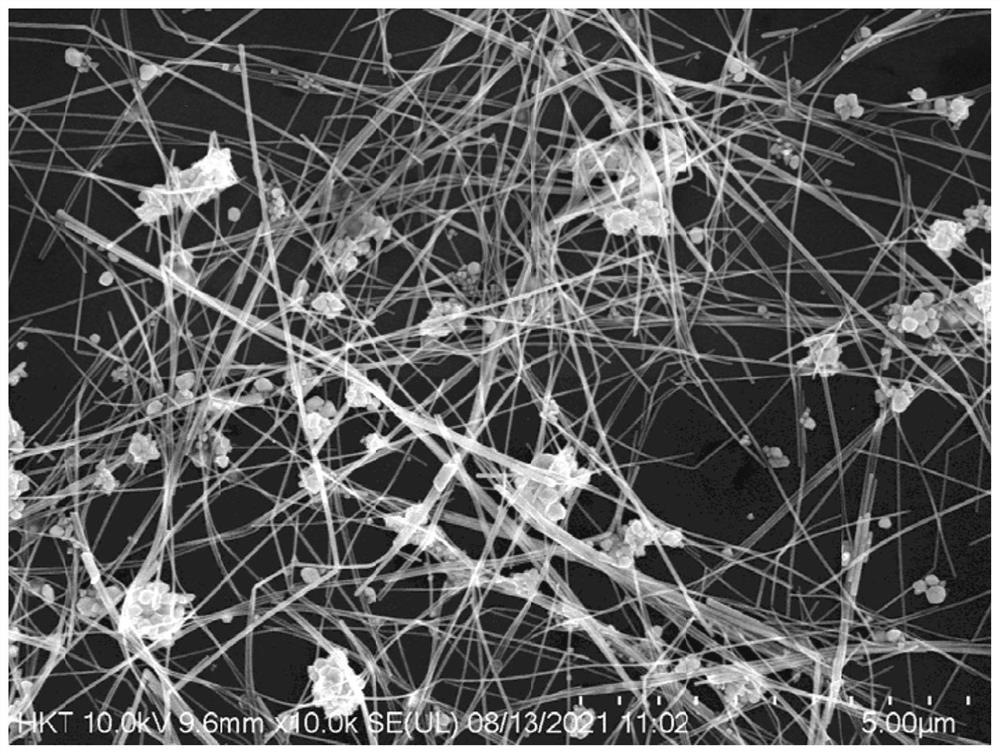

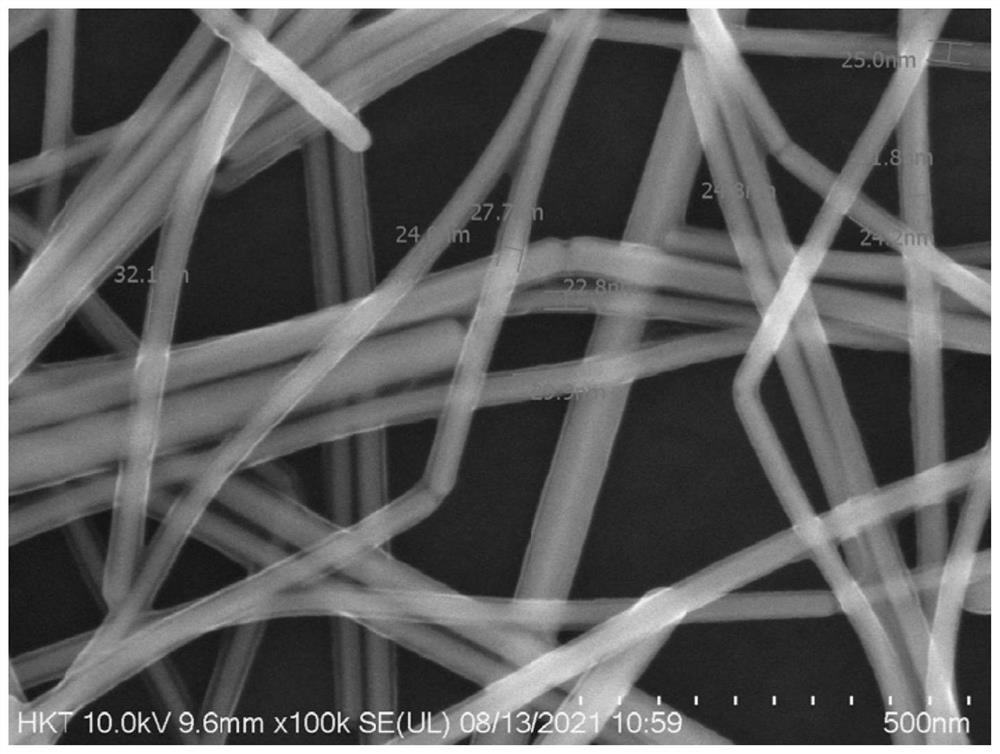

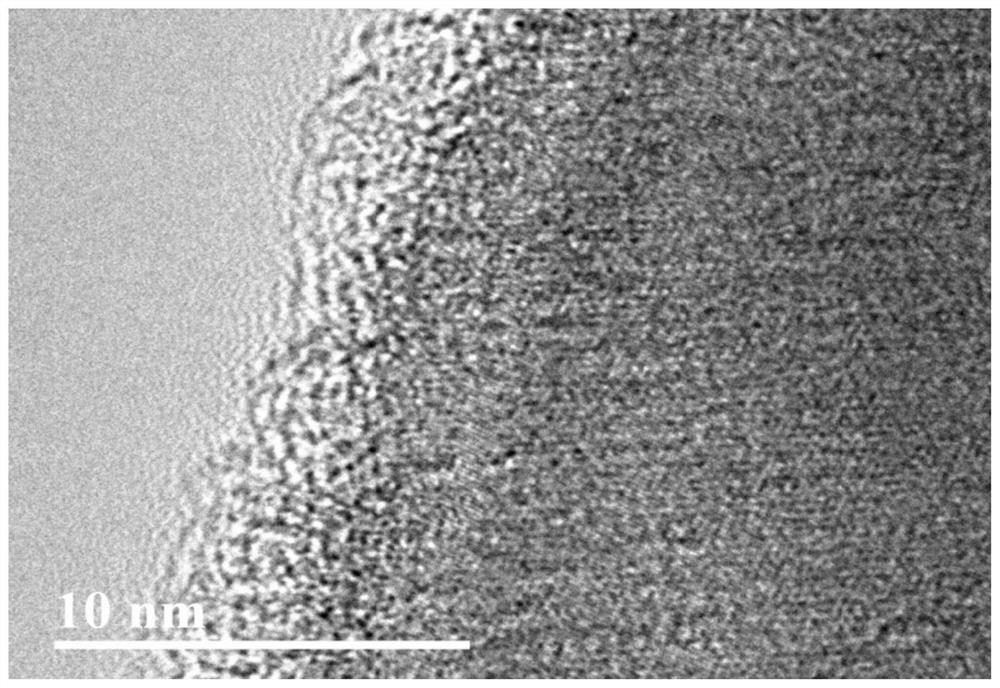

[0038] (4) After the reaction is finished and the temperature is naturally lowered, the reaction product is collected, washed and dried by centrifugation, and the carbon-coated silver nanowire is obtained. Its SEM and TEM characterization pictures are as follows Figure 1-3 shown.

[0039] By observing the shape of carbon-coated silver nanowires using a scanning electron microscope (SEM), see figure 1 As shown, the carbon-coated silver nanowires are all linear structures with a relatively high aspect r...

Embodiment 2

[0042] (1) Collect the bamboo, wash it with water and ethanol in turn, and dry it overnight in an oven at 60°C;

[0043] (2) Take silver nitrate 150mg, be dissolved in 160mL water, fully stir it and make it dissolve completely, prepare 0.94mg / mL silver nitrate solution;

[0044] (3) Transfer the silver nitrate solution in step (2) to a 200mL reaction kettle, add 16mg of dried bamboo in step (1), seal the reaction kettle, and react at 150°C for 10h;

[0045] (4) After the reaction is finished and the temperature is naturally lowered, the reaction product is collected, washed and dried by centrifugation, and the carbon-coated silver nanowire is obtained. Its SEM and TEM characterization pictures are as follows Figure 4-6 shown.

[0046] The shape of the carbon-coated silver nanowires is observed with reference to the test method of Example 1. The carbon-coated silver nanowires are all linear structures with a relatively high length and diameter, and the shape is uniform; coa...

Embodiment 3

[0048] (1) Collect the lotus leaves, wash them with water and ethanol in turn, and dry them overnight in an oven at 80°C;

[0049] (2) Take by weighing 500 mg of silver sulfate, dissolve it in 400 mL of water, stir fully to make it dissolve completely, and prepare a 1.25 mg / mL silver sulfate solution;

[0050] (3) Transfer the silver sulfate solution in step (2) to a 600mL reaction kettle, add 120mg of dried lotus leaves in step (1), seal the reaction kettle, and react at 200°C for 12h;

[0051] (4) After the reaction is finished and the temperature is naturally lowered, the reaction product is collected, washed and dried by centrifugation, and the carbon-coated silver nanowire is obtained. Its SEM and TEM characterization pictures are as follows Figure 7-9 shown.

[0052] The shape of the carbon-coated silver nanowires is observed with reference to the test method of Example 1. The carbon-coated silver nanowires are all linear structures with a relatively high length and dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com