Novel hollow combined board

A combined slab and hollow technology, applied in the direction of floors, bridge parts, building components, etc., can solve the problems of poor strength and mechanical performance of hollow slabs, and achieve the effects of improving bearing capacity, convenient construction and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

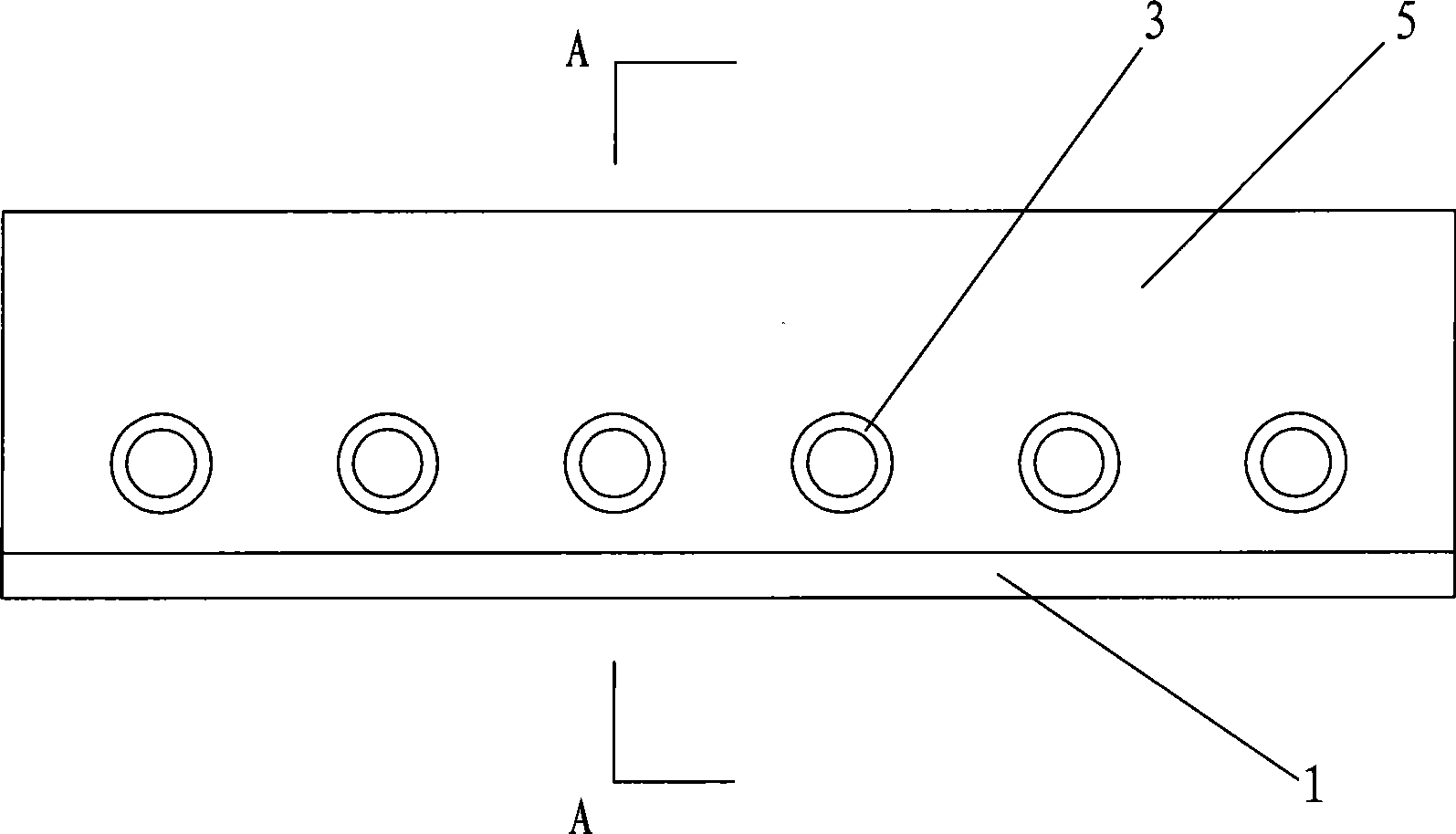

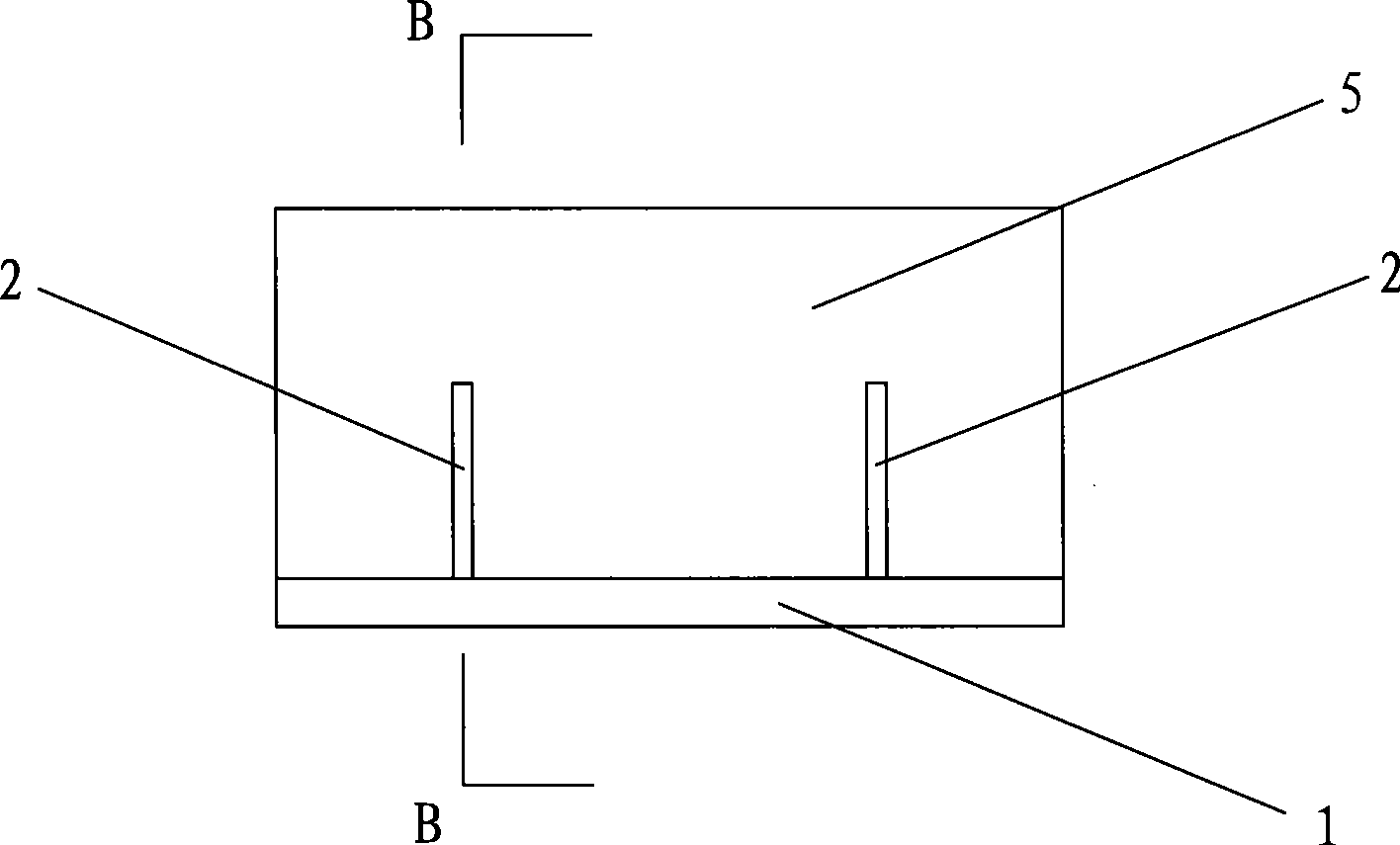

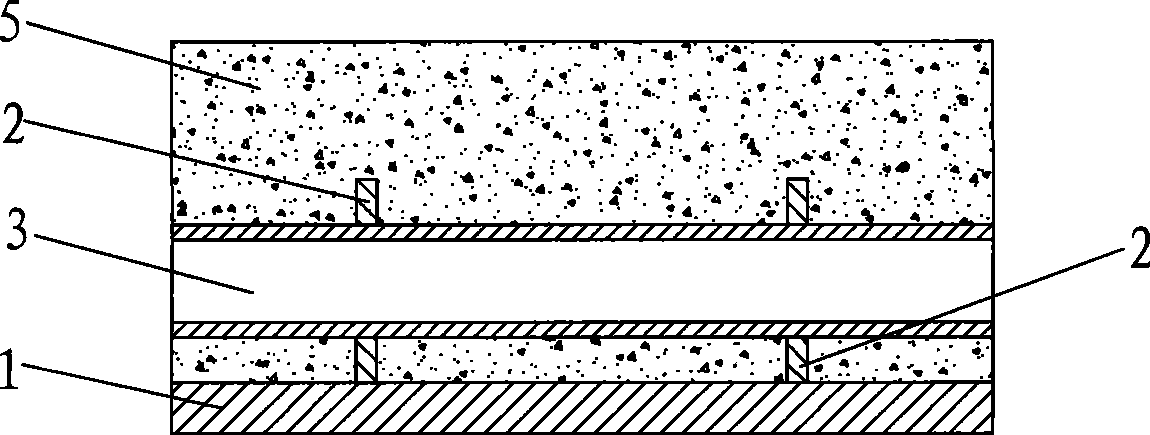

[0023] A novel hollow composite panel of the present invention, such as figure 1 , 2 , 3, 4, and 5, including a flat steel plate 1, a plurality of perforated steel plates 2 and a plurality of steel pipes 3, each perforated steel plate 2 is vertically welded on one side of the flat steel plate 1 in parallel, and the plurality of steel pipes 3 are respectively pierced in each corresponding round hole of each perforated steel plate 2, and the steel pipe 3 is welded together with each corresponding round hole of each perforated steel plate 2, so that the flat steel plate 1, the plurality of perforated steel plates 2 and the plurality of The steel pipes 3 are welded together to form a hollow slab support 4, on which the lightweight aggregate concrete 5 is poured, finally forming a steel plate-light aggregate concrete hollow composite slab. Lightweight aggregate concrete 5 is a kind of concrete formed by using ceramsite as aggregate.

[0024] During processing, first weld the perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com