Concave-convex rod enhanced aluminum oxide nanofiber membrane and preparation method thereof

A technology of aluminum oxide nanofiber and nanofiber membranes, which is applied in the direction of heating/cooling fabrics, artificial filaments made of inorganic materials, non-woven fabrics, etc., can solve the problems of low strength of alumina nanofiber membranes, achieve abundant reserves, low cost, The effect of improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

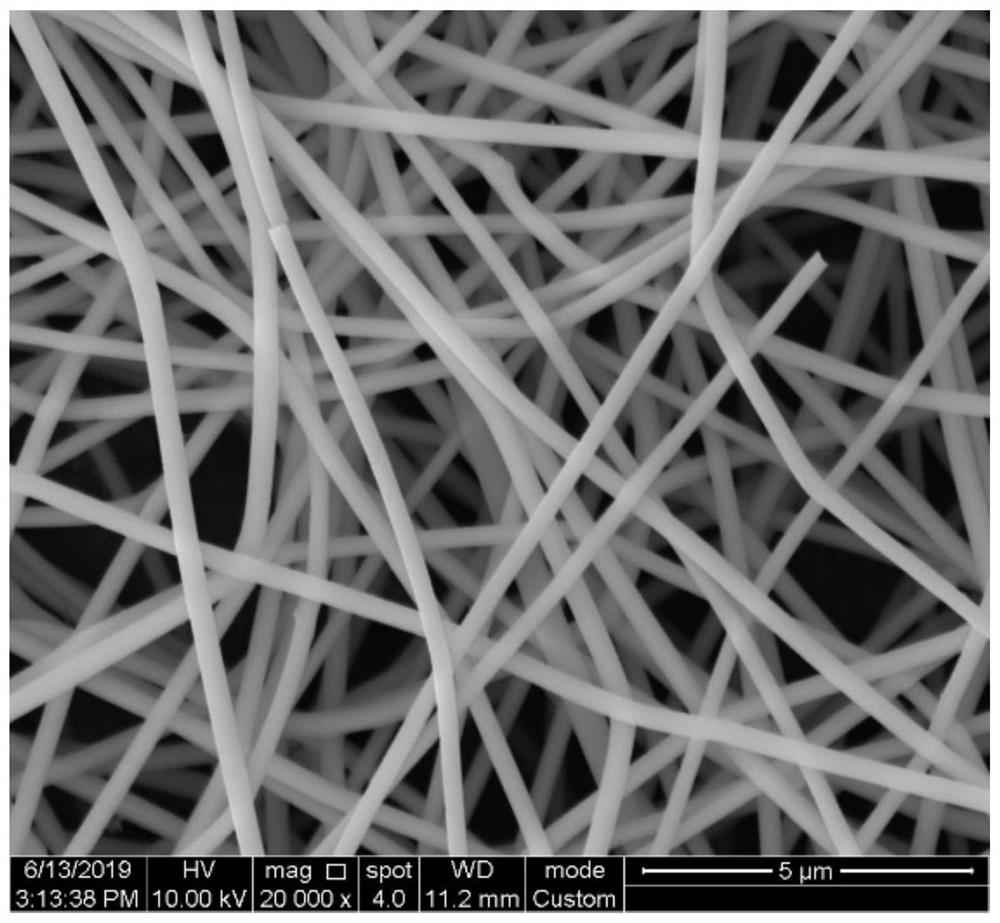

[0031] A method for preparing an attapulgite-reinforced aluminum oxide nanofiber membrane, comprising the following steps:

[0032] Step 1: take a certain amount of inorganic aluminum salt (Al(NO 3 ) 2 .6H 2 O and AlCl 3One or two of them), placed in deionized water, the molar ratio of aluminum salt to deionized water is 1: (10-30), after it dissolves, add glacial acetic acid to adjust the pH value to between 3-5 , and then weigh aluminum isopropoxide or aluminum powder into the solution, the molar ratio of aluminum isopropoxide or aluminum powder to inorganic aluminum salt is (1-3):5, and the solution is heated to 60-100°C under reflux and stirred for 4- 24h, made aluminum sol;

[0033] Step 2: Place the attapulgite in deionized water for ultrasonic treatment for 0.5-4 hours, the mass ratio of the attapulgite to water is 1:(20-200), obtain a dispersed suspension, remove the lower layer of sediment and put it in an oven to dry, according to The mass ratio of the attapulgi...

Embodiment 1

[0039] A method for preparing an attapulgite-reinforced aluminum oxide nanofiber membrane, comprising the following steps:

[0040] Step 1: Weigh 0.05mol of Al(NO 3 ) 2 .9H 2 O, put into 1mol deionized water, after it dissolves, add glacial acetic acid to adjust the pH value to 4, then weigh 0.02mol aluminum isopropoxide and add it to the solution, heat the solution to 80°C and reflux for 4 hours to prepare aluminum sol;

[0041] Step 2: Place the attapulgite in deionized water for 1 hour of ultrasonic treatment. The mass ratio of the attapulgite to water is 1:100 to obtain a dispersed suspension. Remove the lower sediment and put it in an oven to dry. The mass ratio of alumina is added to the attapulgite at a ratio of 1:100 to obtain the attapulgite-doped aluminum sol;

[0042] Step 3: To the attapulgite-doped aluminum sol obtained in step 2, add polyvinylpyrrolidone (K90) according to the mass ratio of the spinning aid to the aluminum oxide in the aluminum sol at a ratio ...

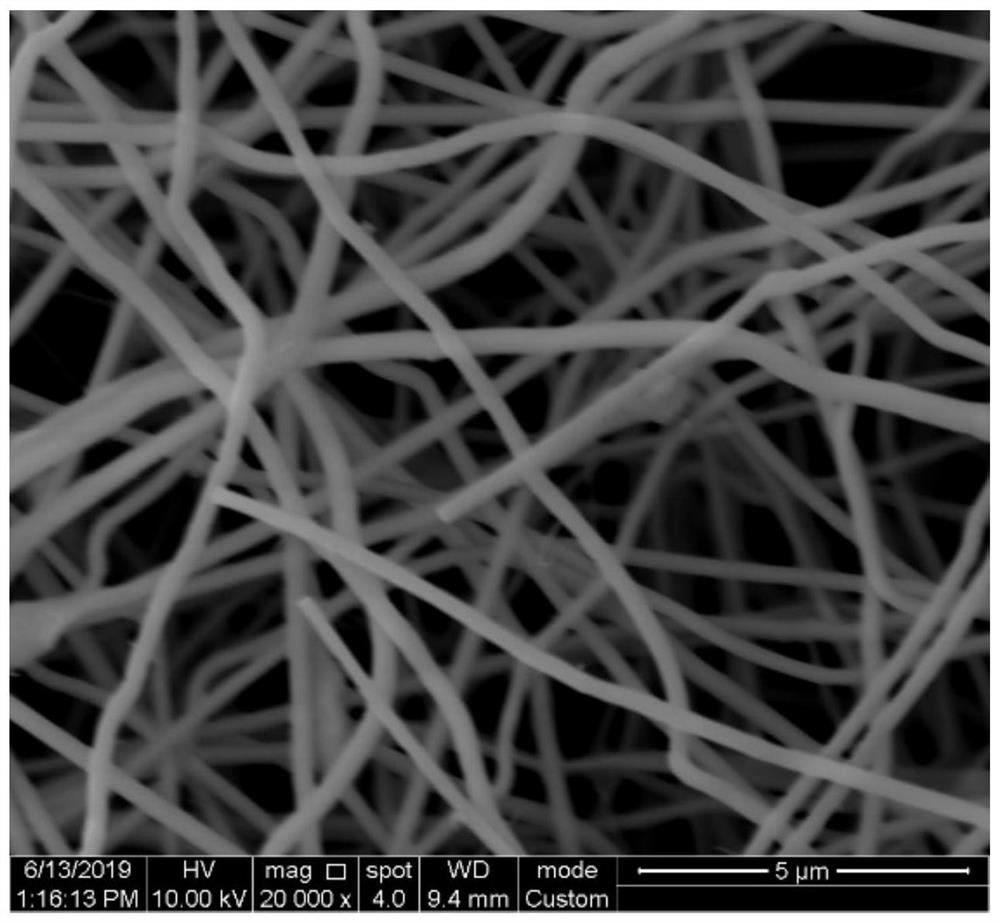

Embodiment 2

[0047] A method for preparing an attapulgite-reinforced aluminum oxide nanofiber membrane, comprising the following steps:

[0048] Step 1: Weigh 0.05mol of Al(NO 3 ) 2 .9H 2 O, put in 1mol deionized water, after it dissolves, add glacial acetic acid to adjust the pH value to 4, then weigh 0.03mol aluminum isopropoxide and add it to the solution, heat the solution to 80°C and reflux for 6 hours to prepare aluminum sol;

[0049] Step 2: Place the attapulgite in deionized water for ultrasonic treatment for 1 hour. The mass ratio of the attapulgite to water is 1:80 to obtain a dispersed suspension. Remove the lower layer of sediment and put it in an oven to dry. The mass ratio of alumina is added to the attapulgite at a ratio of 5:100 to obtain the attapulgite-doped aluminum sol;

[0050] Step 3: To the attapulgite-doped aluminum sol obtained in step 2, add polyvinylpyrrolidone (K90) according to the mass ratio of the spinning aid to the aluminum oxide in the aluminum sol at a...

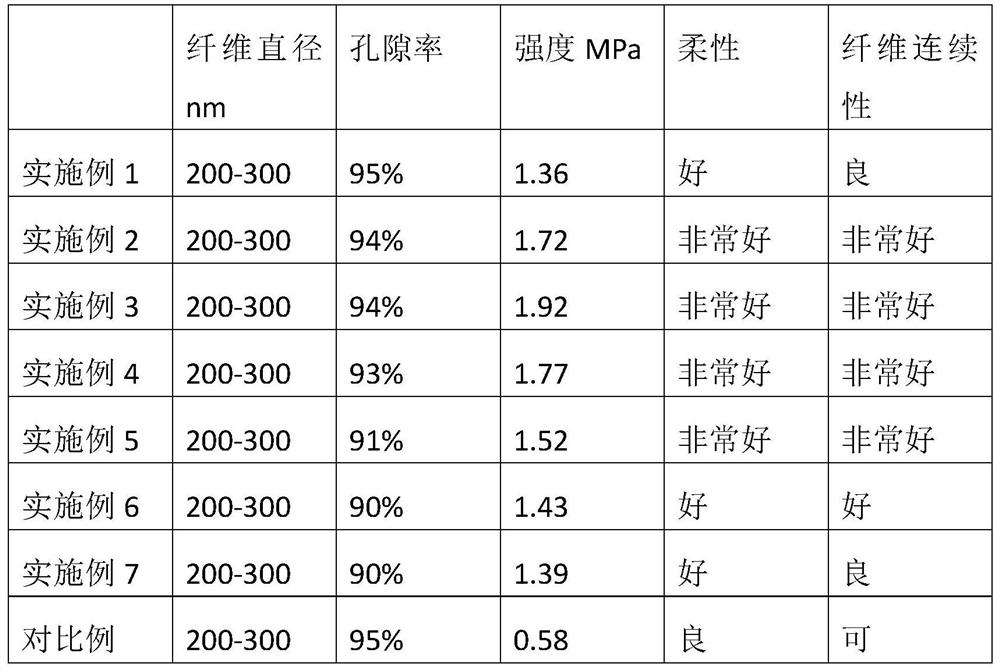

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com