Method for synthesizing titanium-silicon molecular screen

A technology of silicon source and titanium source, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of unstable performance, poor repeatability, and large difference in TS-1 quality, so as to speed up the synthesis speed and catalytic oxidation The effect of improving activity and selectivity and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

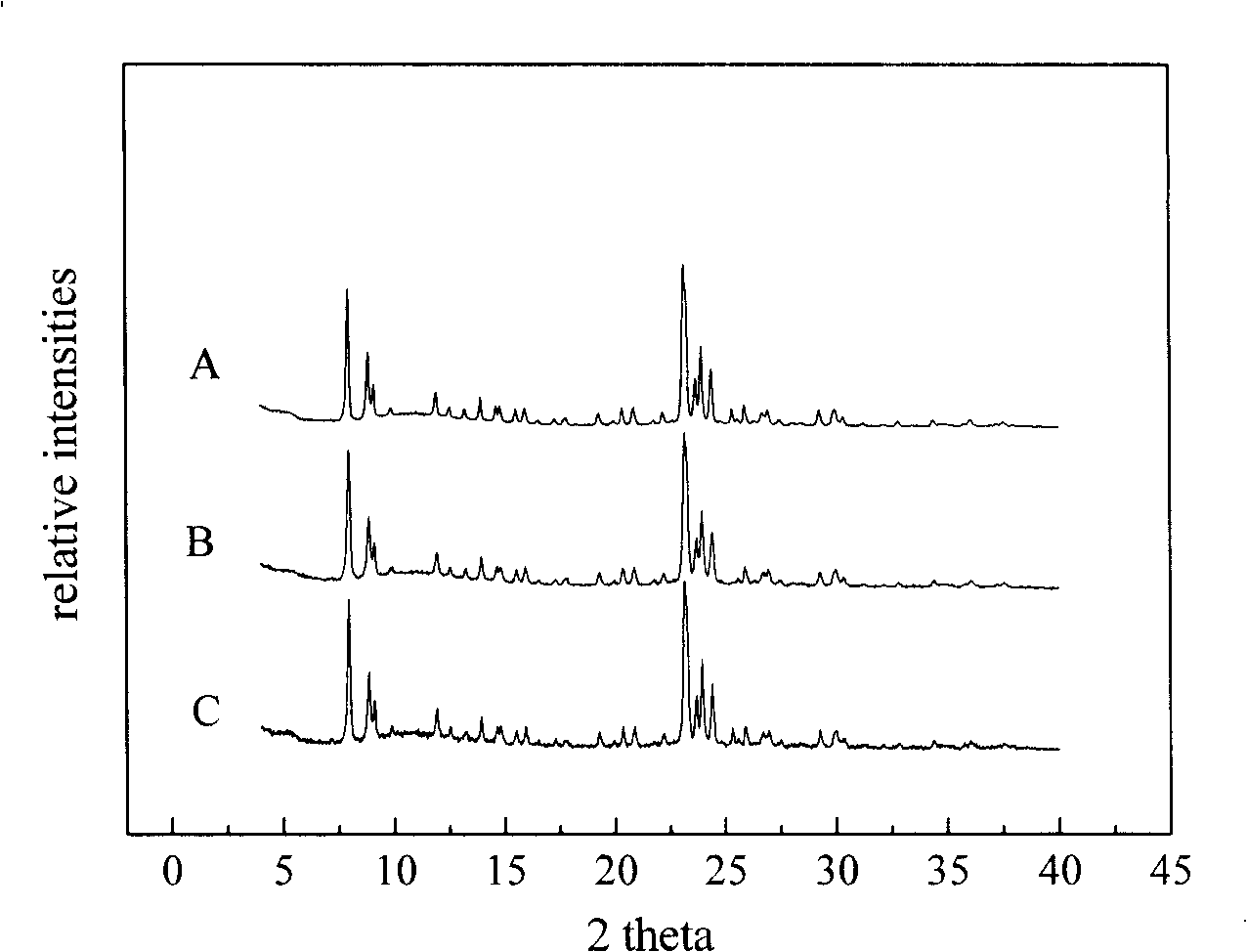

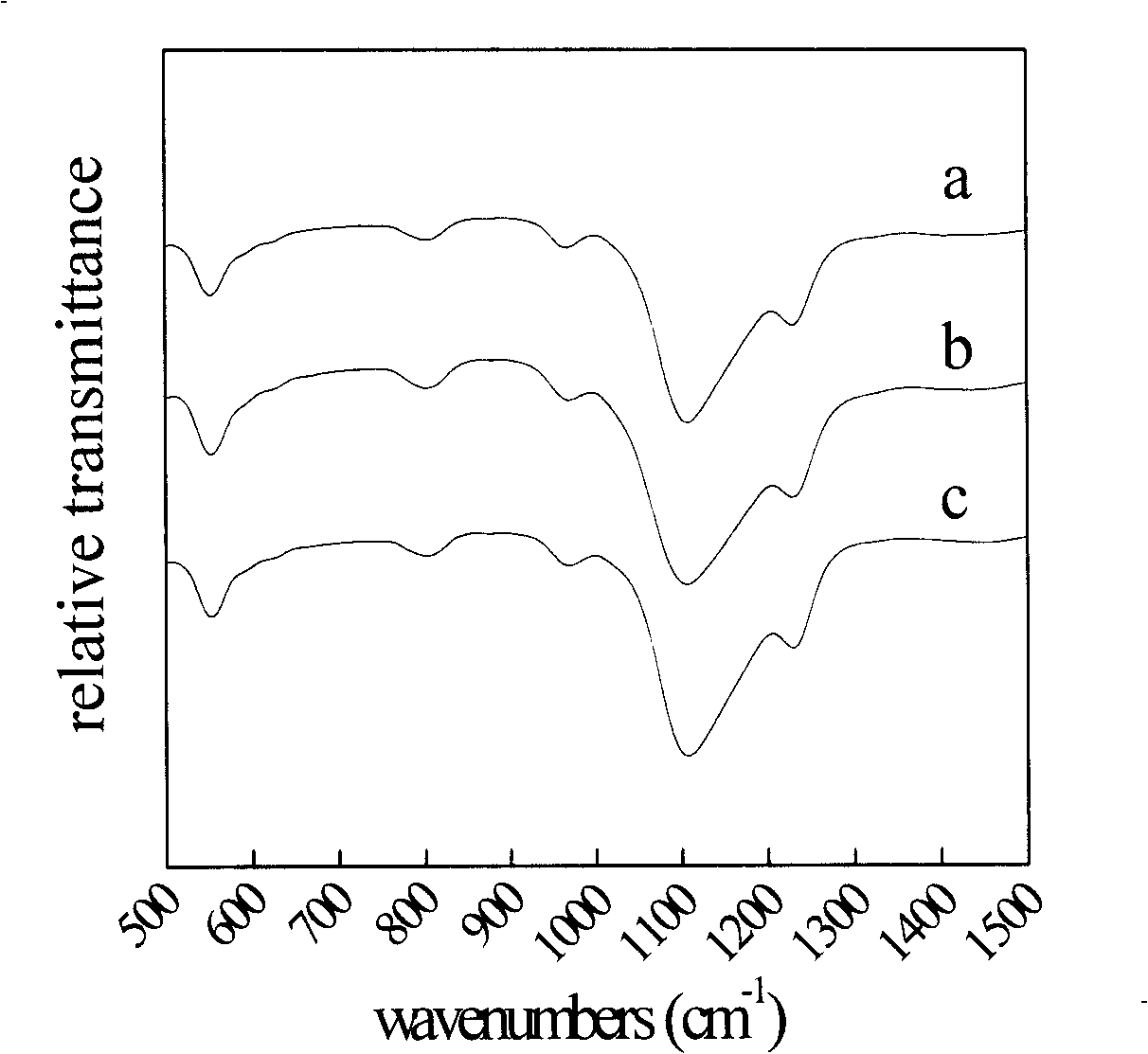

[0033] Add tetraethyl orthosilicate and tetrabutyl titanate successively into the aqueous solution of tetrapropyl ammonium hydroxide and mix them uniformly by ultrasonic stirring, among which tetraethyl orthosilicate, tetrabutyl titanate, tetrapropyl ammonium hydroxide The molar ratio with water is 1:0.04:0.05:25, hydrolyzed at normal pressure and 40° C. for 2 hours to obtain titanium and silicon hydrolysis solution. Put the titanium and silicon hydrolyzate into a sealed stainless steel reaction kettle, crystallize at 170°C and autogenous pressure for 24 hours, filter the resulting crystallized product, wash with water, and dry at 110°C for 120 minutes, then dry it at 550°C ℃ for 3 hours to obtain TS-1 molecular sieve. The yield is about 90%. Its XRD crystal phase diagram is as follows figure 1 Shown in (B), similar to comparative example; Fourier transform infrared spectrogram is as figure 2 As shown in (b), it is also similar to the comparative example, at 960cm -1 The ...

Embodiment 2

[0035] Add tetrabutyl titanate and tetraethyl orthosilicate successively to the aqueous solution of tetrapropyl ammonium hydroxide and ultrasonically stir and mix uniformly to obtain titanium and silicon hydrolysis solution, in which tetraethyl orthosilicate, tetrabutyl titanate, The molar ratio of tetrapropylammonium hydroxide and water is 1: 0.1: 0.15: 55. Put this titanium and silicon hydrolyzate into a stainless steel sealed reaction kettle, and crystallize it for 72 hours at a temperature of 150° C. and under autogenous pressure. The crystallized product was filtered, washed with water, dried at 110°C for 120 minutes, and then calcined at 550°C for 3 hours to obtain TS-1 molecular sieve. The yield is about 89%. Its XRD crystal phase diagram is as follows figure 1 Shown in (C), similar to comparative example; Fourier transform infrared spectrogram is as figure 2 Shown in (c), similar to the comparative example, in the infrared spectrum at 960cm -1 The infrared absorpti...

Embodiment 3

[0037] Add tetraethyl orthosilicate and tetrabutyl titanate to the aqueous solution of tetrapropylammonium hydroxide and triethanolamine respectively, and ultrasonically stir and mix evenly, then mix and ultrasonically stir for a period of time to obtain titanium and silicon hydrolysis solution, in which orthosilicic acid The molar ratio of tetraethyl ester, tetrabutyl titanate, tetrapropyl ammonium hydroxide, triethanolamine and water is 1: 0.2: 0.15: 0.15: 85, put the titanium and silicon hydrolyzate into a stainless steel sealed reaction kettle, and After crystallization at 130°C and autogenous pressure for 96 hours, the obtained crystallized product was filtered, washed with water, dried at 110°C for 120 minutes, and then calcined at 550°C for 3 hours to obtain TS-1 molecular sieve. The yield is about 88%, and it is proved by X-ray diffraction (XRD) and infrared spectrum (IR) that the obtained sample is TS-1 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com