Method and apparatus for firearm sound suppression

a technology for suppressors and firearms, applied in the direction of muzzle attachments, weapons, weapon components, etc., can solve the problems of reducing the material strength requirements of key suppressor components, adversely affecting the performance and mechanical durability of both firearms and suppressors, and increasing the operator's exposure to ejected gasses and propellants, etc., to reduce visible flash and muffle noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]The method of the current invention provides a means to maximize firearm suppressor efficiency with regards to maximizing sound attenuation while minimizing physical size and weight and minimizing firearm backpressure and manufacturing cost.

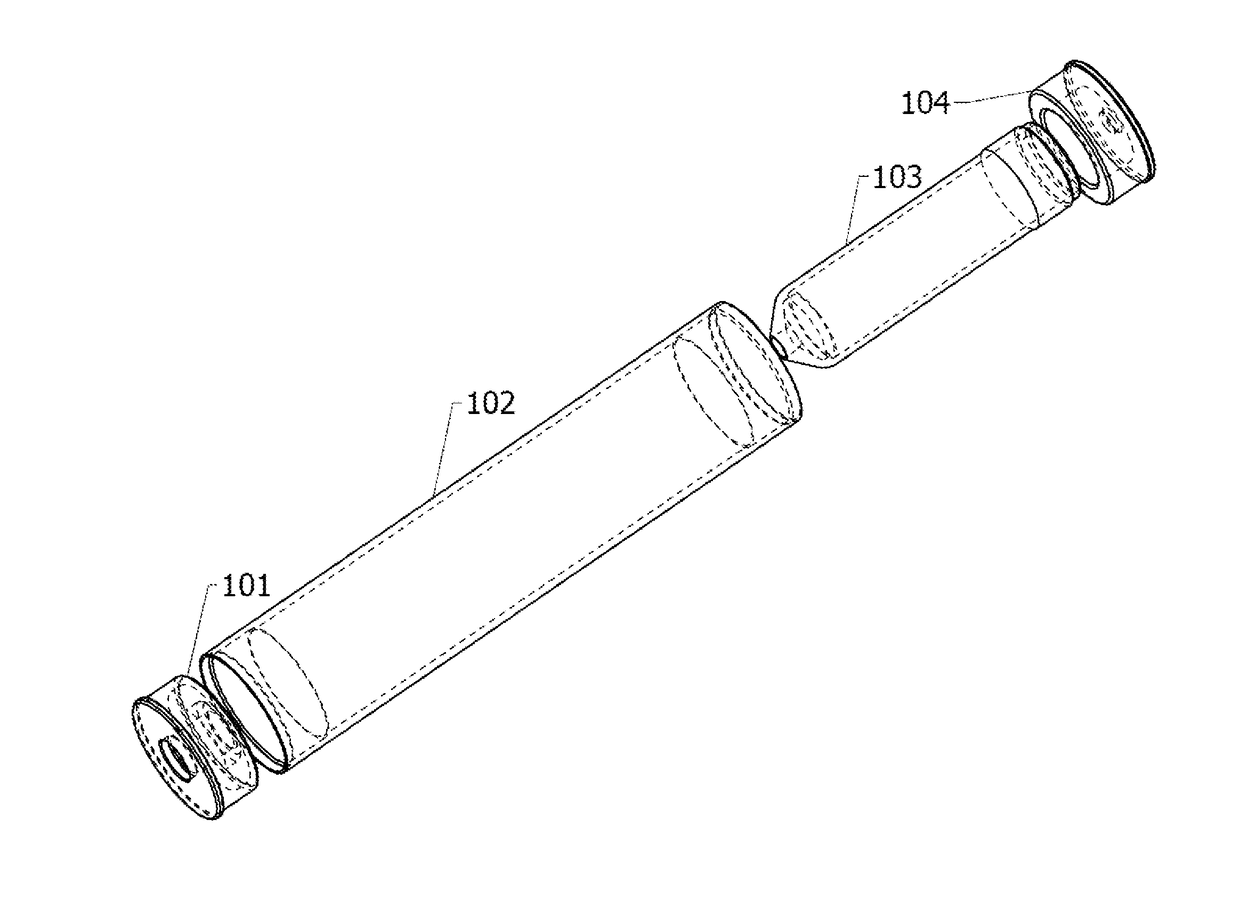

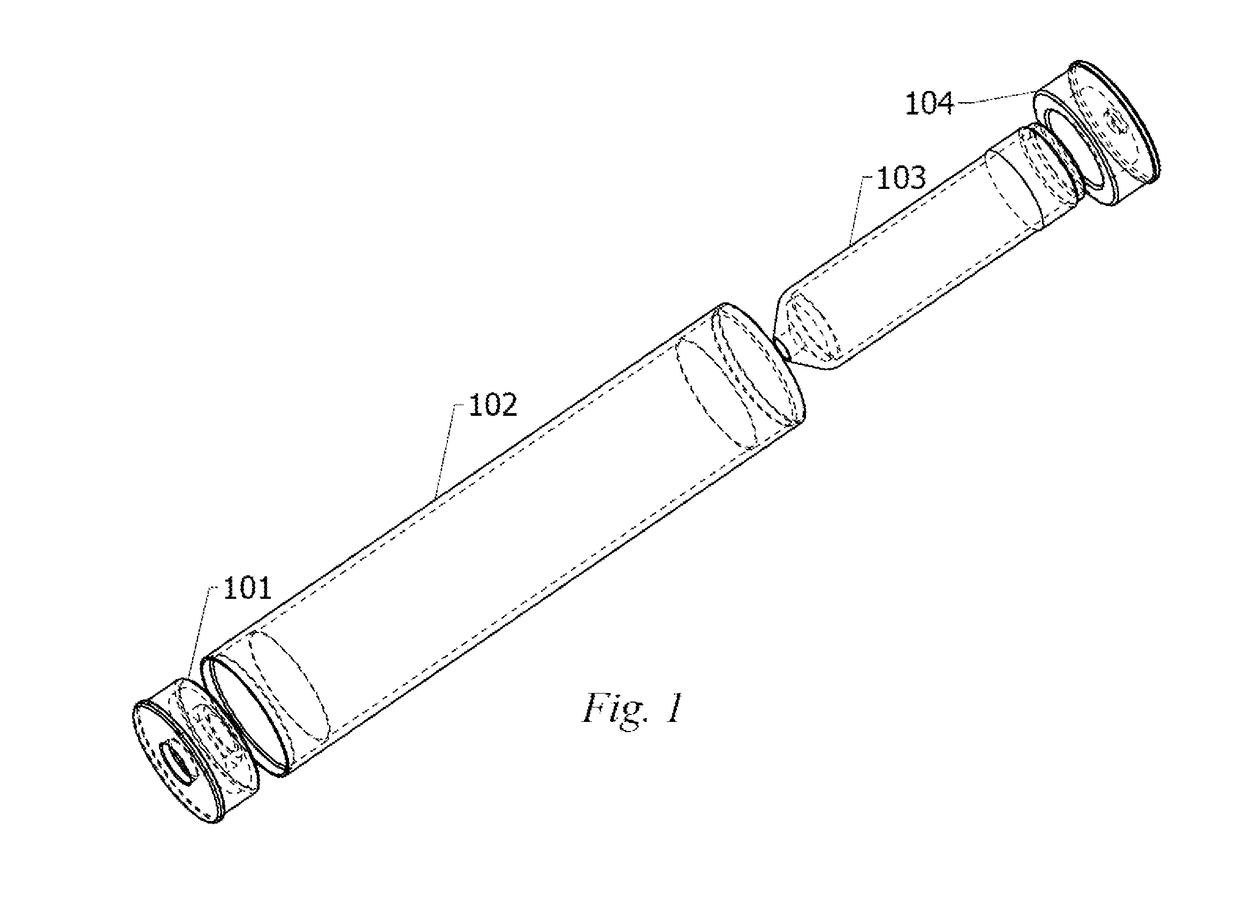

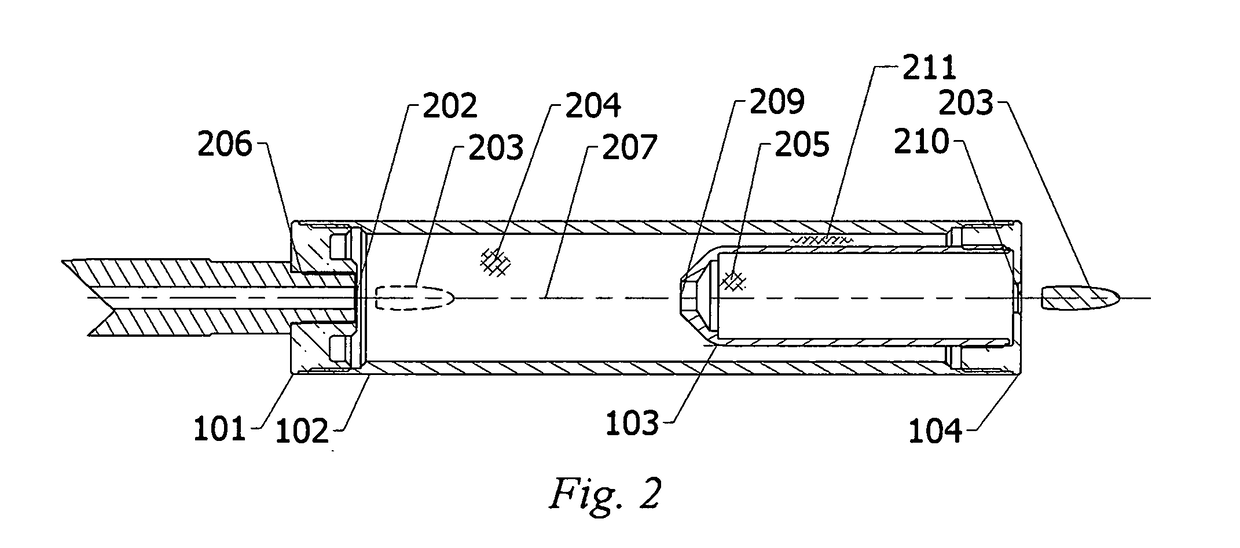

[0011]In the preferred embodiment, the present invention consists of an outer cylinder (102) closed at the proximal end with a planar base (101) and the distal end with a planar cap (104). Within this outer cylinder (102) is a separate inner cylinder (103) of a lesser diameter and length. The outer cylinder (102) and inner cylinder (103) are coaxial and share the distal planar end cap (104) and have a separation of the proximal ends of the cylinders. Holes coaxial with the assembly provide a means to attach the device to the firearm muzzle (202) at the proximal planar end of the device (206), for the projectile (203) and ejection mass to enter the proximal end of the outer cylinder (202) and for the projectile (203) and ejection mass to exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com