Regeneration method of lithium extraction system

An extraction and system technology, which is applied in the field of lithium extraction system regeneration, can solve the problems of complicated lithium separation technology, and achieve the effect of simple regeneration method, guaranteed recycling and high regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

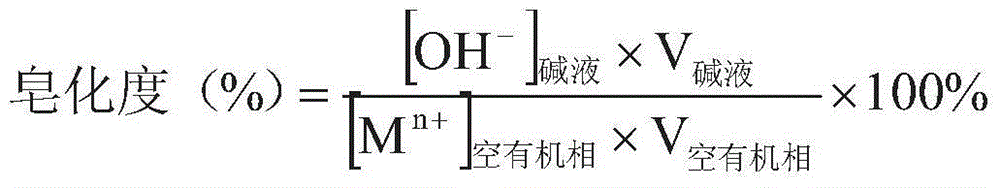

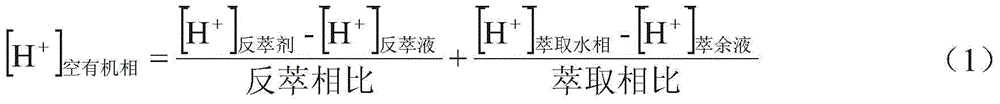

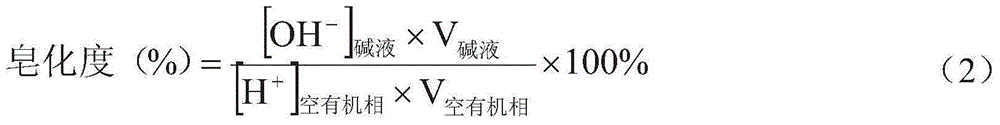

Method used

Image

Examples

Embodiment 1

[0041] First take 40mL of the empty organic phase HFeCl 4 ·nS; then with 4.00mol·L -1 The NaOH solution is the lye, the above empty organic phase HFeCl under different degrees of saponification 4 nS saponification, analysis of saponification phase separation effect under different degrees of saponification. After saponification, stand still and separate phases to obtain the extracted organic phases of each group under different degrees of saponification after regeneration.

[0042] In order to illustrate the effect of the above saponification regeneration, when the regenerated extraction organic phase is used for circular extraction, the Li in the aqueous phase is extracted + The concentration is 5g·L -1 , the extraction ratio is 5:1.

[0043] In this example, the above-mentioned empty organic phase HFeCl 4 nS comes from an extractant with a volume fraction of 80% TBP, FeCl 3 The extraction process is the co-extraction agent and 20% sulfonated kerosene is the diluent. A...

Embodiment 2

[0049] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that the empty organic phase HFeCl 4 nS comes from a 50% N by volume fraction, N-bis(2-ethylhexyl)acetamide as extractant, FeCl 3 The extraction process is the co-extraction agent and 50% sulfonated kerosene is the diluent. Among them, the extraction of Fe in the organic phase 3+ The concentration is 0.187mol L -1 ; After the extraction and stripping process, calculated by measurement, the empty organic phase HFeCl 4 · H in nS + The concentration is 0.176mol L -1 .

[0050] Get the empty organic phase HFeCl after the above stripping 4 nS 20mL, with 1.712mol L -1 The NaOH solution was used as lye for saponification, and the phase separation effect of saponification under different degrees of saponification was analyzed. After saponification, stand still an...

Embodiment 3

[0057] First take 20 mL of the empty organic phase HFeCl 4 ·nS; then with 4.00mol·L -1 The NaOH solution is the lye, the above empty organic phase HFeCl under different degrees of saponification 4 nS saponification, analysis of saponification phase separation effect under different degrees of saponification. After saponification, stand still and separate phases to obtain the extracted organic phases of each group under different degrees of saponification after regeneration.

[0058] In order to illustrate the effect of the above saponification regeneration, when the regenerated extraction organic phase is used for circular extraction, the Li in the aqueous phase is extracted + The concentration is 1.87g·L -1 , the extraction ratio is 2:1.

[0059] In this example, the above-mentioned empty organic phase HFeCl 4 nS comes from a 5% TBP / 45% N by volume fraction, N-di(2-ethylhexyl) acetamide as extractant, FeCl 3 The extraction process is the co-extraction agent and 50% sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com