Preparation method of plant-mixed hot recycled asphalt mixture

An asphalt mixture and thermal regeneration technology, applied in the field of road engineering, can solve the problems of increasing the difference in the production mix ratio of the recycled mixture, reducing the economic advantage of the recycled mixture, affecting the performance of the recycled mixture, etc. Easy to achieve and prevent whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

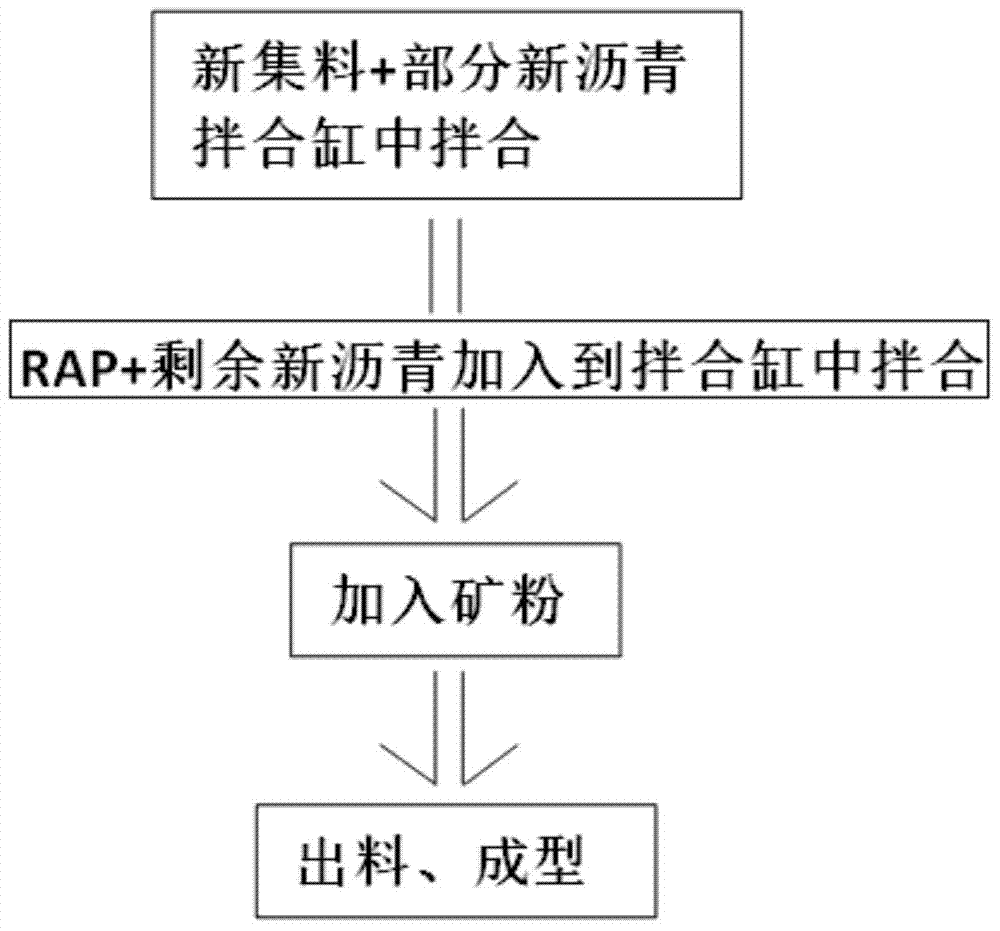

Method used

Image

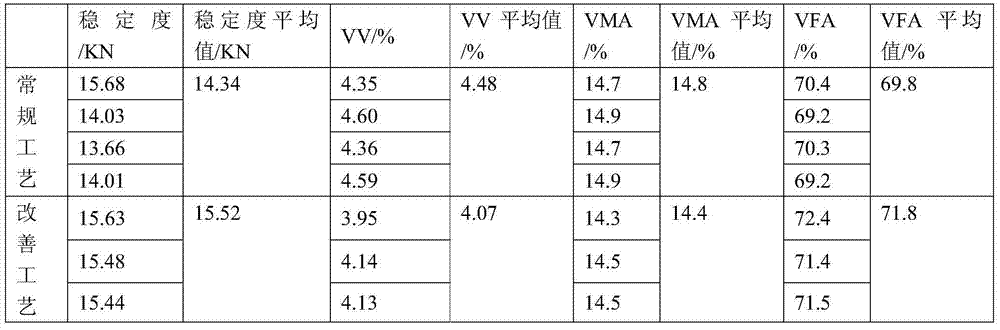

Examples

Embodiment 1

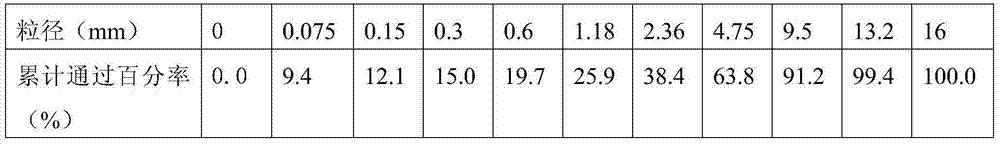

[0029] Indoor test example: The RAP used in the experiment is the material of the same source and the same particle size. First, the RAP is sampled, and then the sample is subjected to an extraction test. The test shows that the asphalt content of the RAP is 4.55%. A screening test was performed on the old aggregate obtained in the extraction test. The test results are shown in Table 1. Rotary evaporation method is used to recover the old asphalt after extraction test, and perform performance index test. The test results are shown in Table 2.

[0030] Table 1 Gradation of old aggregates in RAP

[0031]

[0032] Table 2 Test results of old asphalt performance indexes in RAP

[0033] Penetration degree 25℃(0.1mm)

Softening point (℃)

Ductility 15℃(cm)

12.1

74.6

Brittle

[0034] The new aggregate is limestone, and the ore powder is limestone ore powder. The relative density of the new aggregate was tested, and the test results are shown in Table 3.

[0035] Table 3 Test results...

Embodiment 2

[0058] Indoor test example: The RAP used in the experiment is a material of the same source with different particle sizes, and is counted as RAP1 (0-16mm) and RAP2 (0-25mm) respectively. First sample two kinds of RAP respectively, and then carry out extraction test on the sample. The test shows that the asphalt content of RAP1 is 4.55% and the asphalt content of RAP2 is 3.45%. A screening test was performed on the old aggregate obtained in the extraction test. The test results are shown in Tables 6 and 7. Rotary evaporation method is used to recover the old asphalt after extraction test, and perform performance index test. The test results are shown in Table 8.

[0059] Table 6 Gradation of old aggregates in RAP1

[0060]

[0061] Table 7 Gradation of old aggregates in RAP2

[0062] Particle size (mm)

0

0.075

0.15

0.3

0.6

1.18

2.36

Cumulative passing percentage (%)

0.0

9.0

10.2

11.8

14.2

17.6

24.1

Particle size (mm)

4.75

9.5

13.2

16

19

26.5

31.5

Cumulative passing percent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com