Comprehensive heat energy utilizing type active coke purifying and regenerating process system and active coke purifying and regenerating process method

A treatment system and active coke technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of low energy utilization and low energy utilization, and achieve enhanced recycling, improved utilization, and regeneration high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

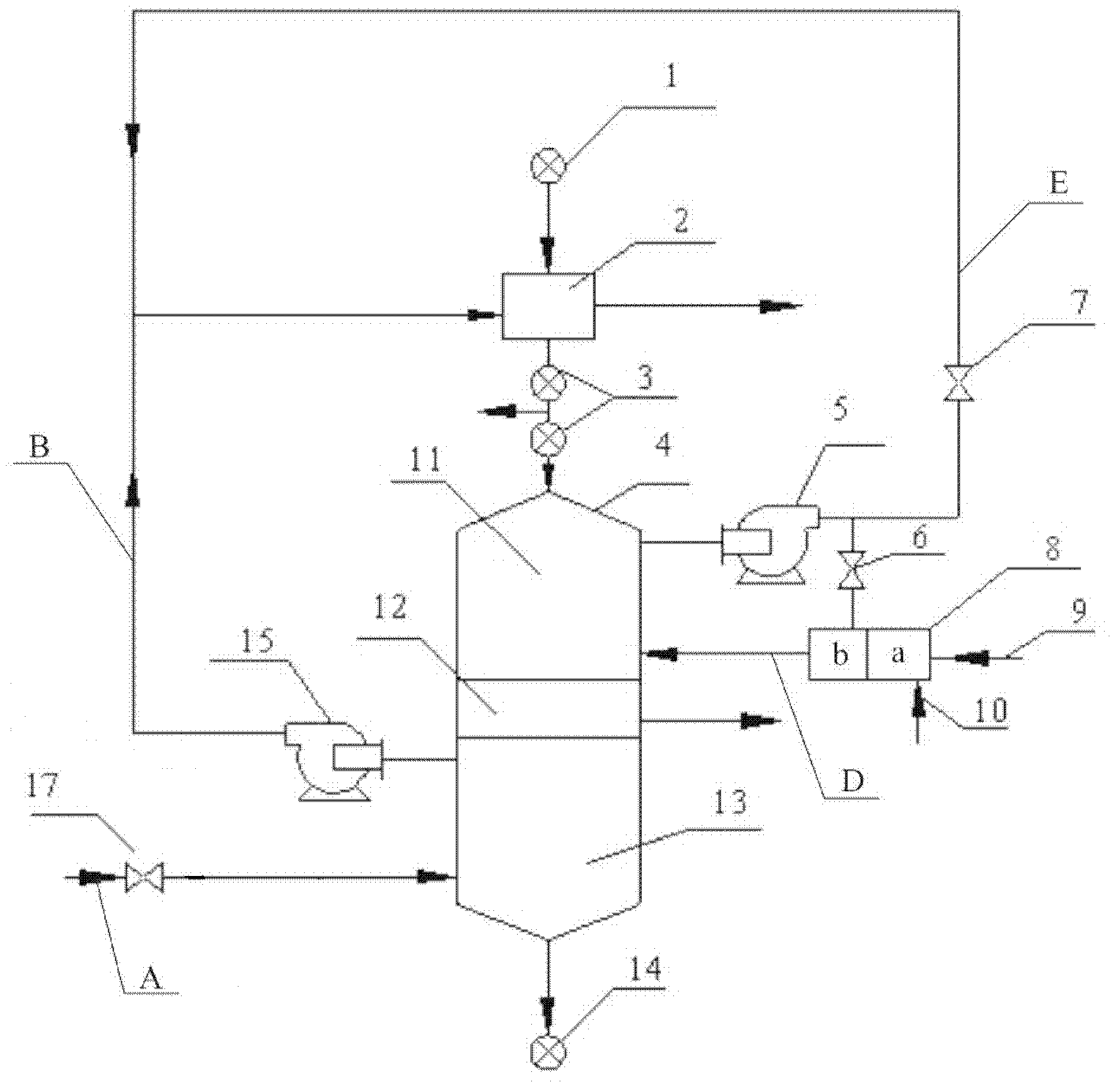

[0038] combine figure 1 Describe the thermal energy comprehensive utilization type activated coke purification and regeneration treatment system of this embodiment, the treatment system includes a regeneration device, a preheating device, a heating device and a heat exchange device; the regeneration device includes a regeneration tower 4, and the regeneration tower 4 is from top to bottom In turn, it is divided into heating section 11, regeneration section 12 and cooling section 13; the preheating device includes a drying tower 2, which is arranged above the regeneration tower 4 and communicates with the regeneration tower 4 through pipelines; the heating device includes a hot blast furnace 8. The first fan 5, the hot blast stove 8 and the first fan 5 are connected to the regeneration tower 4 through pipelines to form a heat transfer medium circulation pipeline D, which is used to heat the active coke in the heating section 11 of the regeneration tower; the heat transfer medium...

Embodiment 2

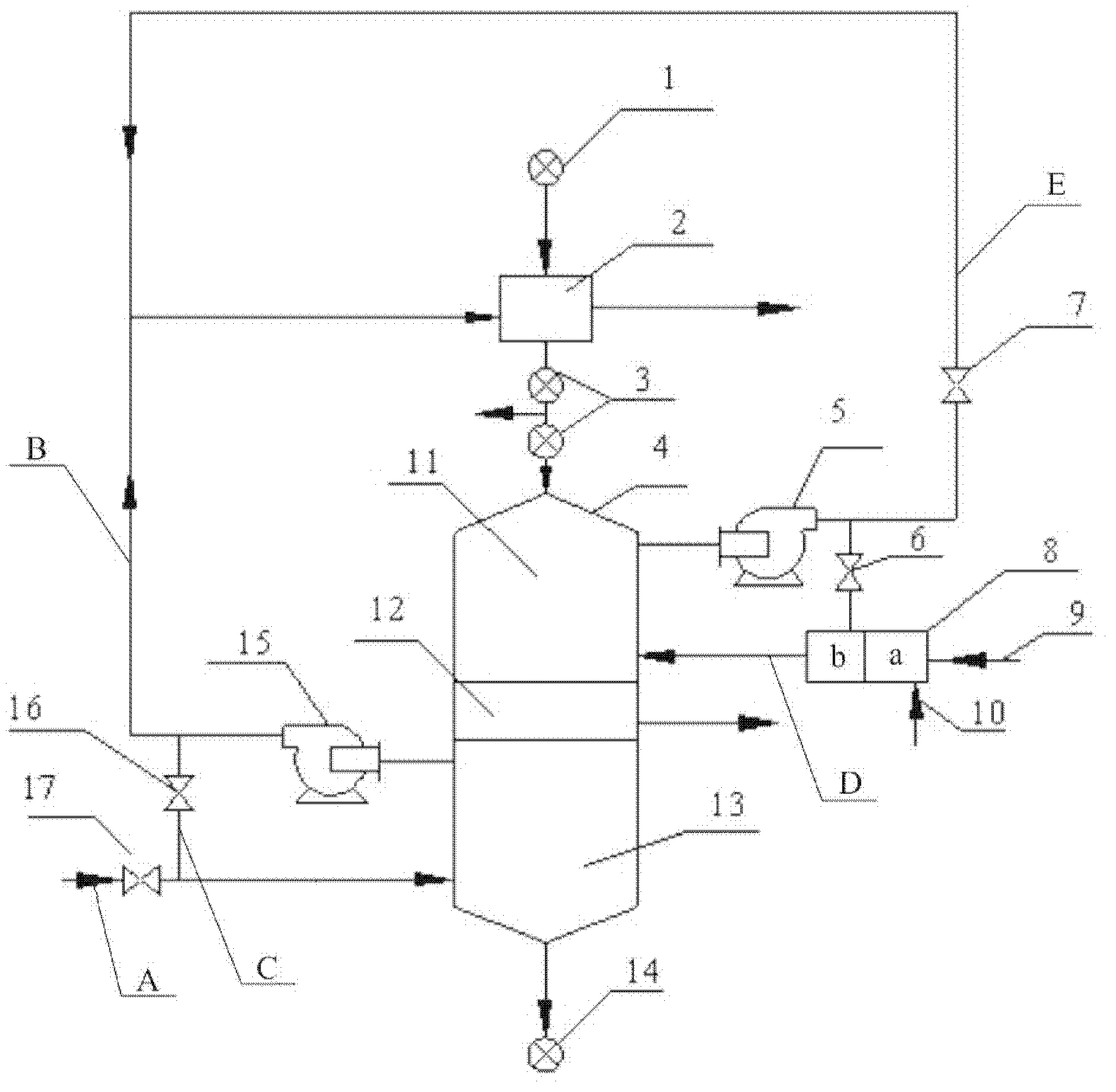

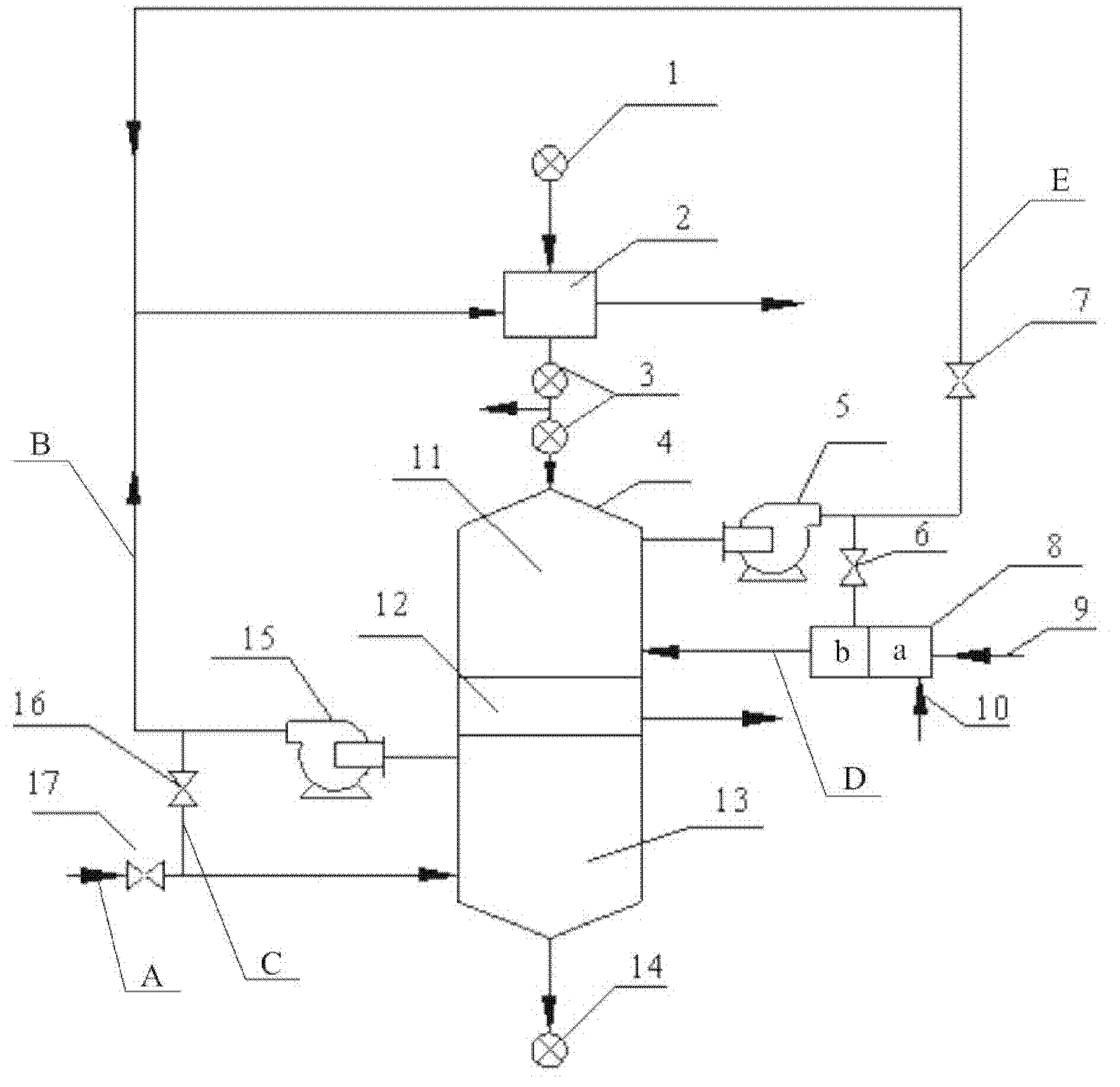

[0045] combine figure 2 Illustrate that the heat energy comprehensive utilization type activated coke purification and regeneration treatment system of this embodiment is different from Embodiment 1 in that: the heat exchange device includes a second fan 15, a normal temperature air input pipeline A, and a hot air output pipeline B, The normal temperature air input pipeline A and the hot air output pipeline B are respectively connected to the regeneration tower 4, and the second fan 15 is arranged on the hot air output pipeline B to send the hot air after heat exchange into the drying tower 2 Preheat the active coke. One end of the air input port of the normal temperature air input pipeline A is provided with a fourth valve 17 to control the flow of normal temperature air, and a hot air return mixing pipeline for mixing part of the hot air with normal temperature air is also connected to the hot air output pipeline B C, the hot air return mixing line C is connected to the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com