Method for treating sulfur- and hydrocarbon-containing foul waste gas

A treatment method and exhaust gas technology, applied in separation methods, chemical instruments and methods, containers, etc., can solve problems such as danger and safety, and achieve the effects of compensating for temperature reduction, increasing the concentration of regeneration gas, and not producing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

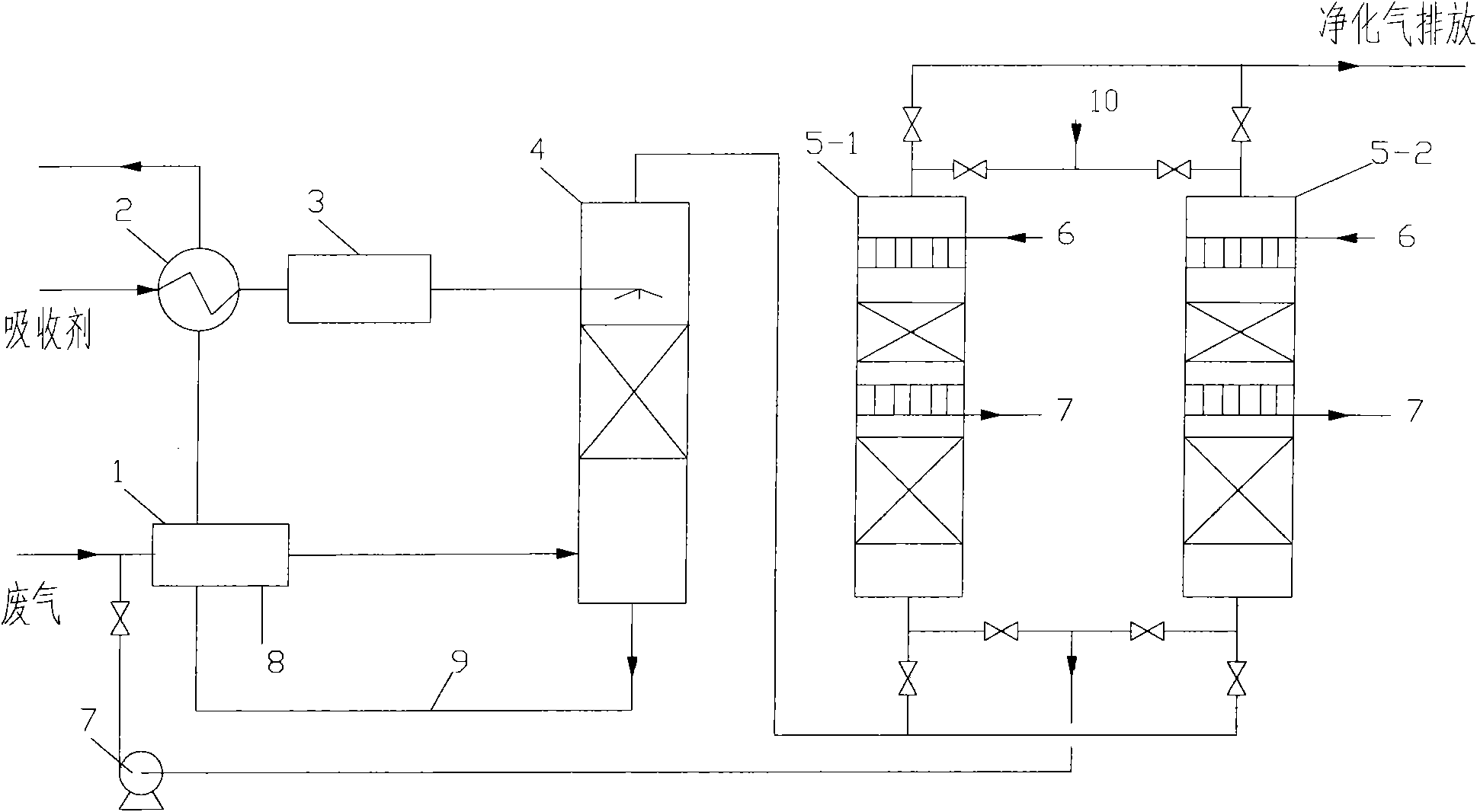

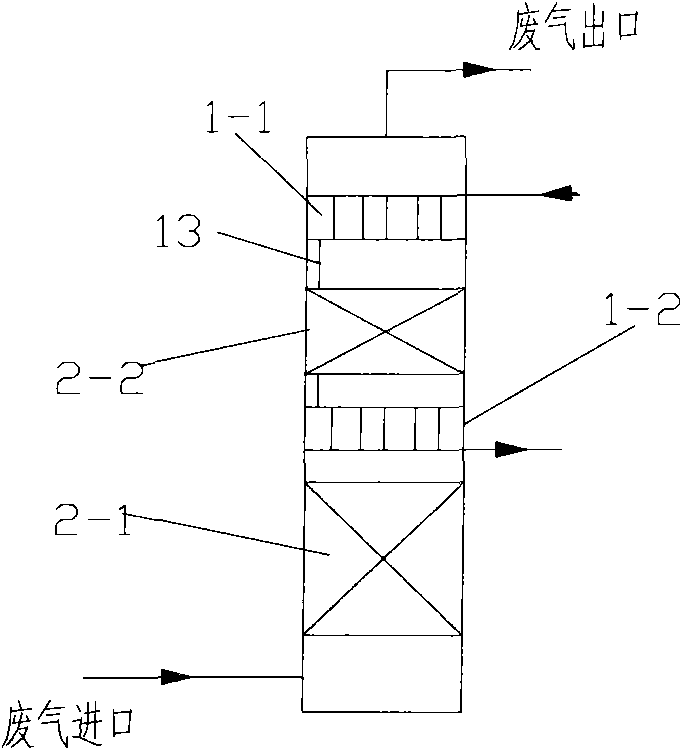

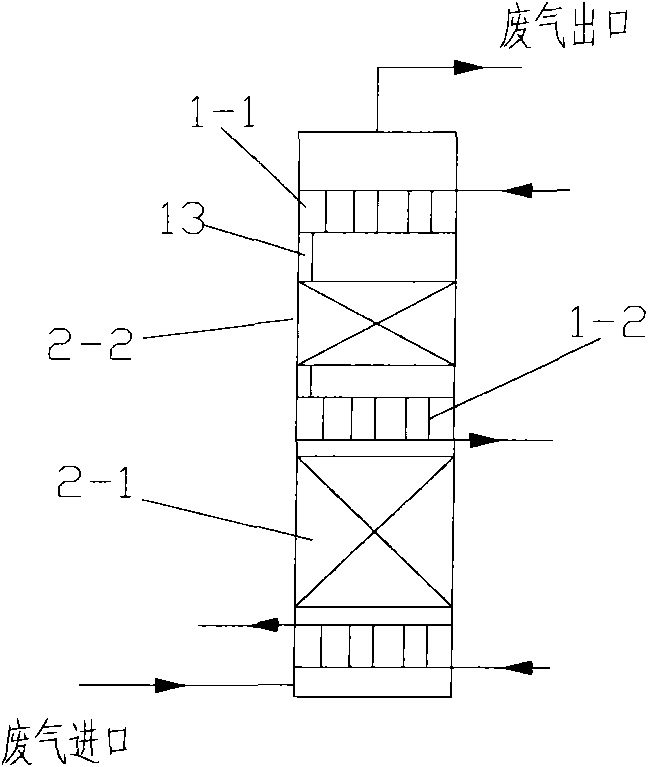

Method used

Image

Examples

Embodiment 1

[0037] The concentration of organic sulfide DMDS in the breathing gas of a sulfur-containing sewage tank is 200mg / m 3 , the hydrocarbon concentration is 30% (volume ratio), the absorption liquid adopts catalytic cracking diesel fraction with an initial boiling point of 150°C, and the absorption liquid-gas ratio is 100L / m 3 . The absorbent is cooled to 20°C, the adsorbent is silica gel and activated carbon, and the bed volume ratio is 1:1 for adsorption for 48 hours, then it is heated and regenerated in vacuum, and the regeneration gas returns to the exhaust gas inlet port, and the desorption rate can reach 95%. During regeneration, saturated steam with a temperature of 150°C passes between the adsorbent beds of the adsorption tower. After the exhaust gas is treated by this process, the total hydrocarbon concentration of the outlet gas is less than 120mg / m 3 , DMDS concentration cannot be detected after the absorption tower. Purified gas concentration and total emissions are...

Embodiment 2

[0043] Exhaust gas from a refining and chemical unit, in which the organic sulfide methyl sulfide is 50mg / m 3 , the total hydrocarbon concentration is 60% (volume ratio), and water vapor is 6%. The absorbent is ordinary second-line diesel with an initial boiling point of 190°C. After the diesel oil is cooled, the temperature is 10°C. After heat exchange between the exhaust gas and the rich absorption diesel oil, it enters the absorption tower for absorption, and the absorption liquid-gas ratio is 2L / m 3 , and then enter the adsorption tower for adsorption. The lower layer of the adsorption tower is made of modified silica gel, and the upper layer is activated carbon. The volume ratio of modified silica gel and activated carbon is 2:1. During regeneration, the steam heater temperature is 100°C, and the regeneration cycle is 72h. The regeneration gas is returned to the exhaust gas inlet. After purification by this process, the concentration of hydrocarbons in the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com