Method for improving garlic oil yield

A technology for garlic essential oil and yield, which is applied in the directions of essential oils/spice, fat production, etc., can solve the problems of improving distillation efficiency, increasing the yield of garlic essential oil, etc., and achieves the effects of increasing yield and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

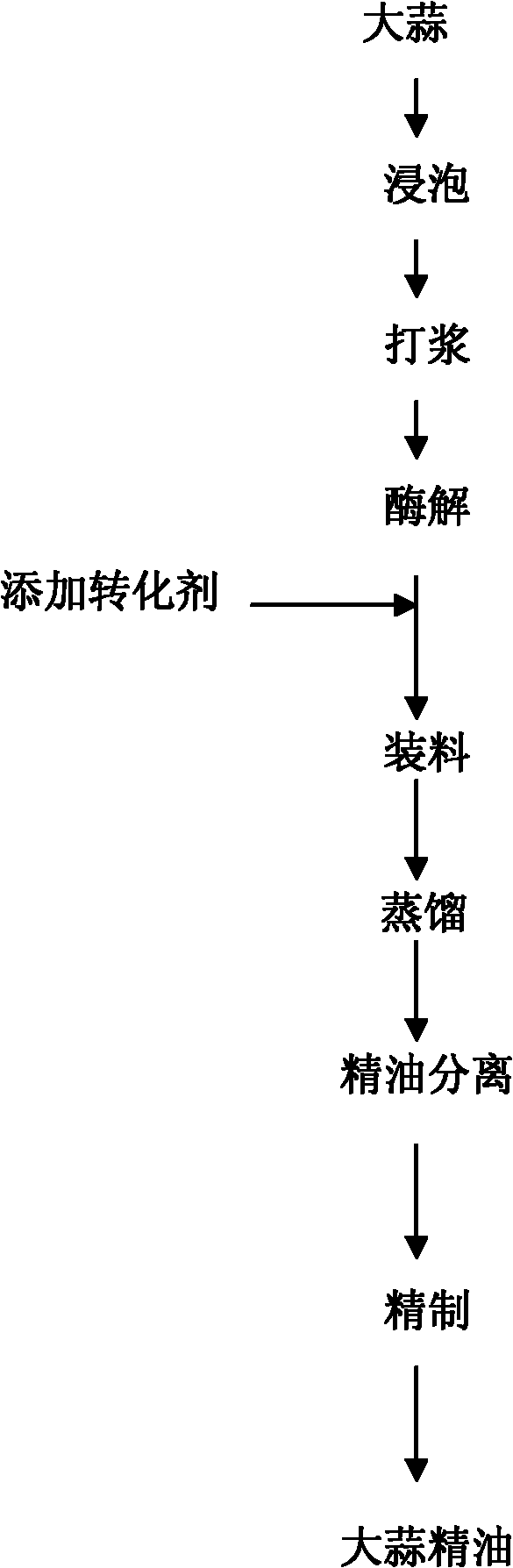

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, carry out according to the following steps:

[0042] The first step is pretreatment: put fresh garlic cloves in 5 times drinking water, soak for 2 hours, rinse with running water to remove impurities such as soil and garlic skin. Control the dry clear water, place it on a crusher and crush it into garlic pulp with a particle size of about 200 mesh.

[0043] The second step makes alliin enzymatic hydrolysis: add alliinase activity regulator (30 grams of blue alum, 1 kilogram of milk of lime at 20 degrees Baume, 20 grams of bittern at 20 degrees Baume, by every ton of garlic pulp, at room temperature Enzymolysis for 1 hour, so that alliin is completely converted into allicin. The enzymolysis process ends when no alliin is detected. The specific detection method is: standard solution of alliin, and the enzymolysis garlic juice point On the same silica gel sheet, use n-butanol: glacial acetic acid: water (4:1:1) mixture as mobile phase chromatography, and use...

Embodiment 2

[0050] Embodiment 2, identical with embodiment 1 the first, two, four, five, six steps are omitted, and the 3rd step operation that is different from embodiment 1 is:

[0051] The second step is to add alliinase activity regulator, add 50 grams of blue alum, 3 kg of lime milk, and 100 grams of bittern per ton of garlic pulp.

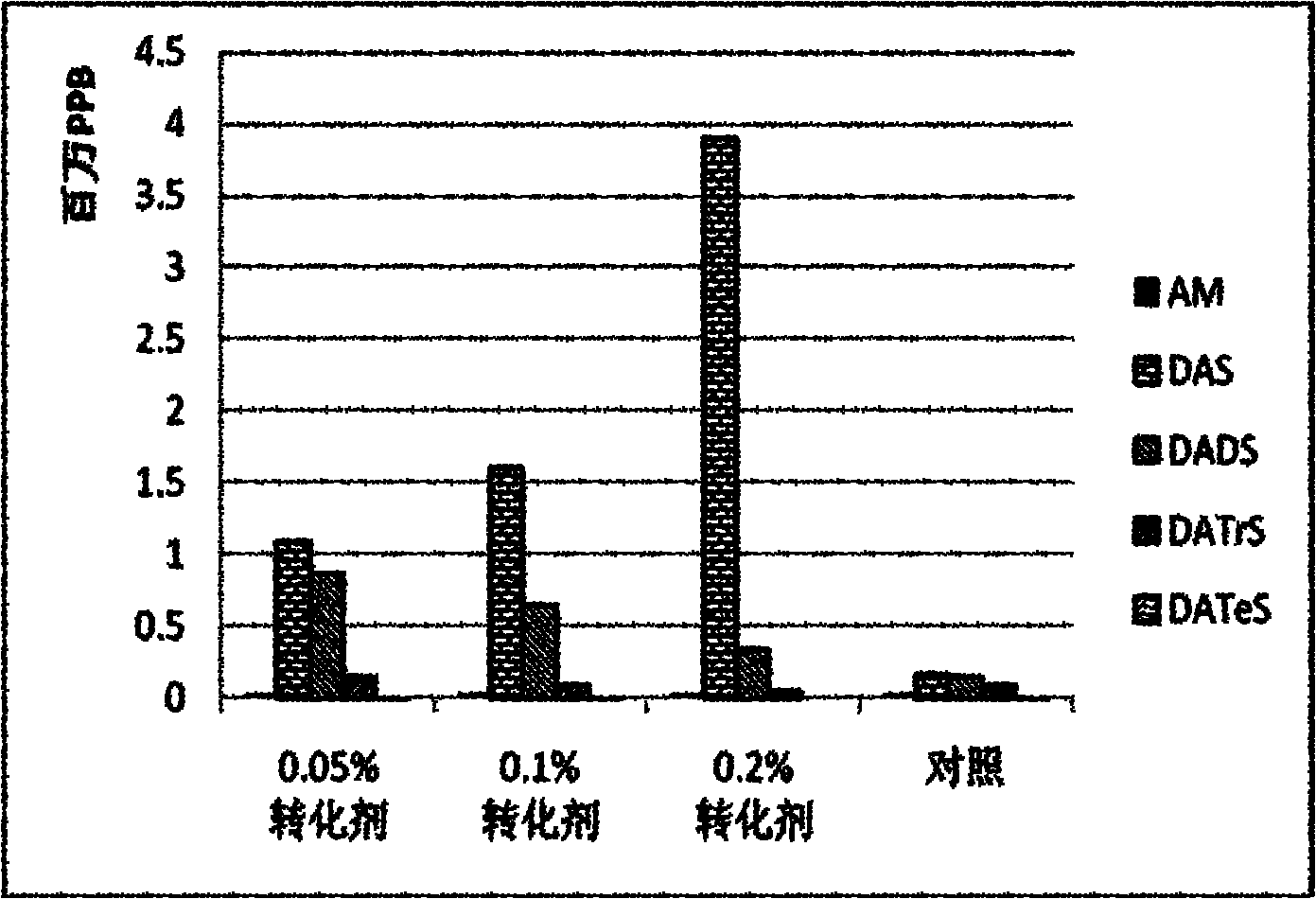

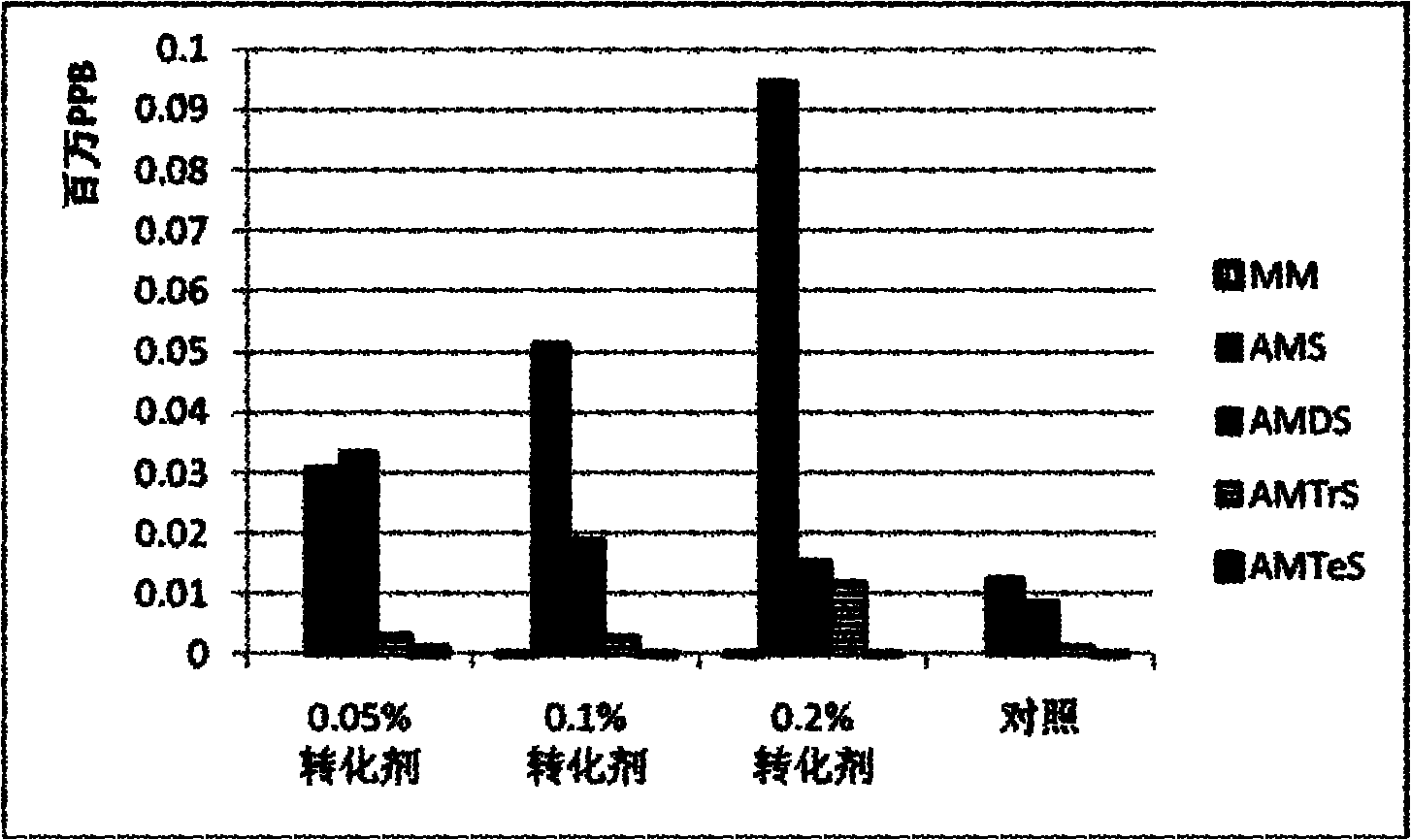

[0052] The third step is to add conversion agent: add hydrochloric acid 0.01%, disodium hydrogen phosphate 2.4%, sodium bisulfite 0.5% (both are calculated based on the amount of enzymatic hydrolysis solution), the conversion agent is first dissolved with a small amount of water, and then after adding the enzymatic hydrolysis solution Enter the loading step.

[0053] If enzymolysis and distillation are carried out in the same container, it can be added before distillation, and the yield is 0.65% (W / W).

Embodiment 3

[0054] Embodiment 3, identical with embodiment 1 the first, two, four, five, six steps are omitted, and the third step operation different from embodiment 1 is:

[0055] The second step is to add alliinase activity regulator, add 30 grams of blue alum, 2 kg of lime milk, and 60 grams of bittern per ton of garlic pulp.

[0056] The third step is to add conversion agent: add 0.2% lactic acid, 0.5% sodium bicarbonate, and 0.1% sodium metabisulfite (calculated based on the amount of enzymatic hydrolysis solution). Enter the loading step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com