Rapidly heating distillation device in titanium tetrachloride refining process

A rapid heating and titanium tetrachloride technology, applied in the direction of titanium halide, etc., can solve problems such as corrosion of buildings and equipment, easy burning of nickel wire, and operator injury, etc., to achieve uniform and stable heating, low production costs, and high product quality. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

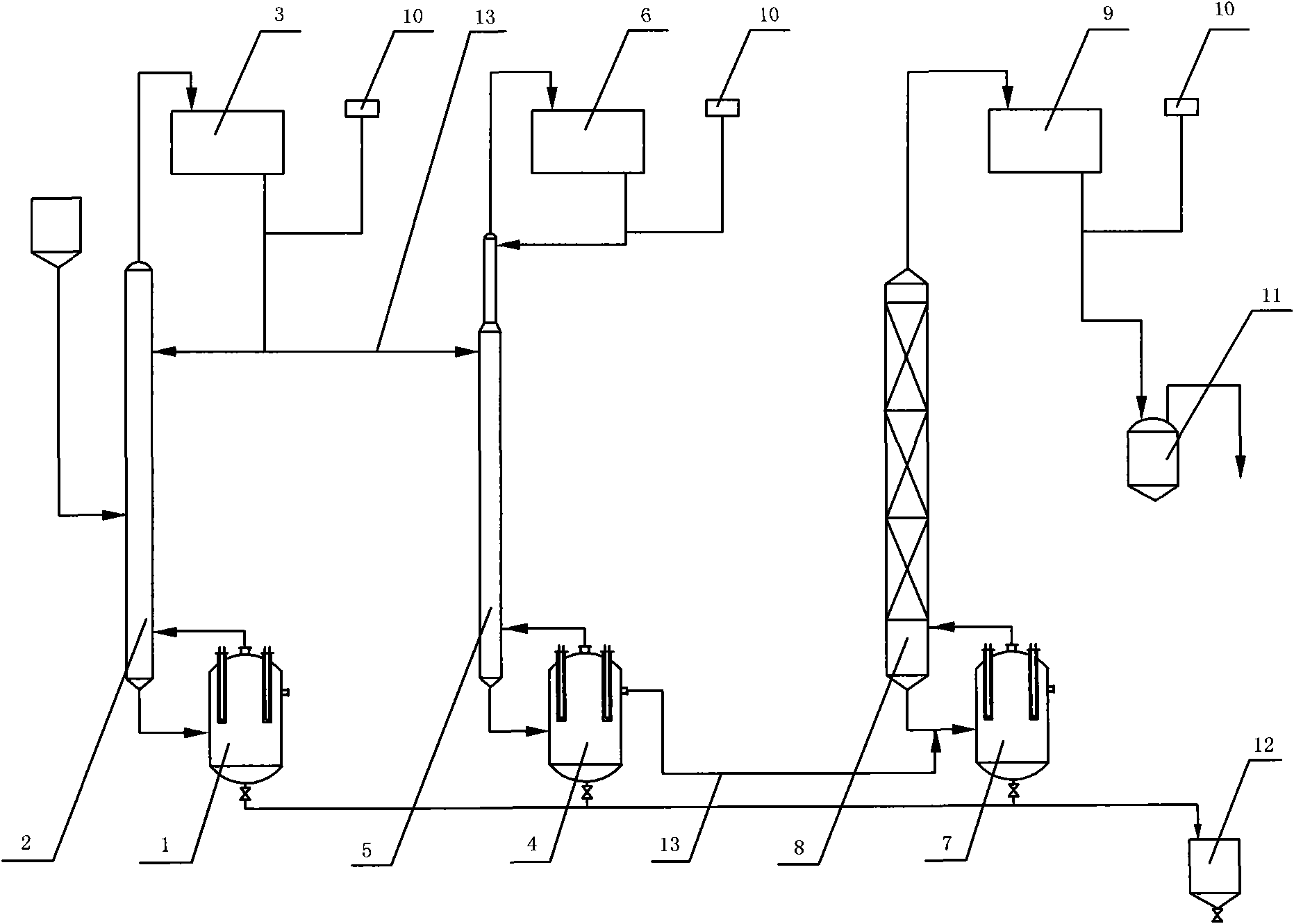

[0026] In conjunction with an annual output of 5,000 tons of titanium tetrachloride production equipment, the specific implementation of a kind of rapid heating distillation device in the refining titanium tetrachloride process of the present invention will be further described with reference to the accompanying drawings:

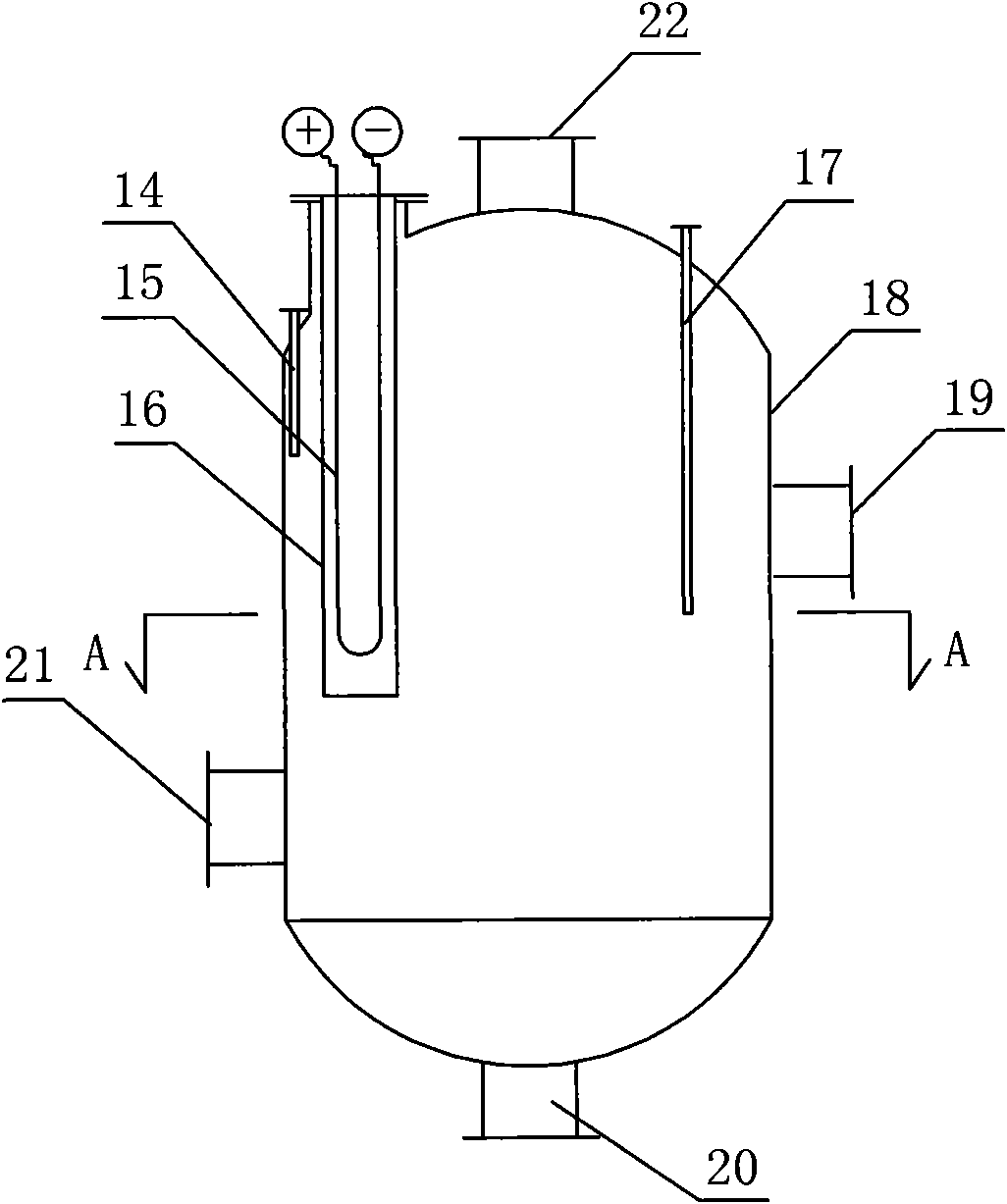

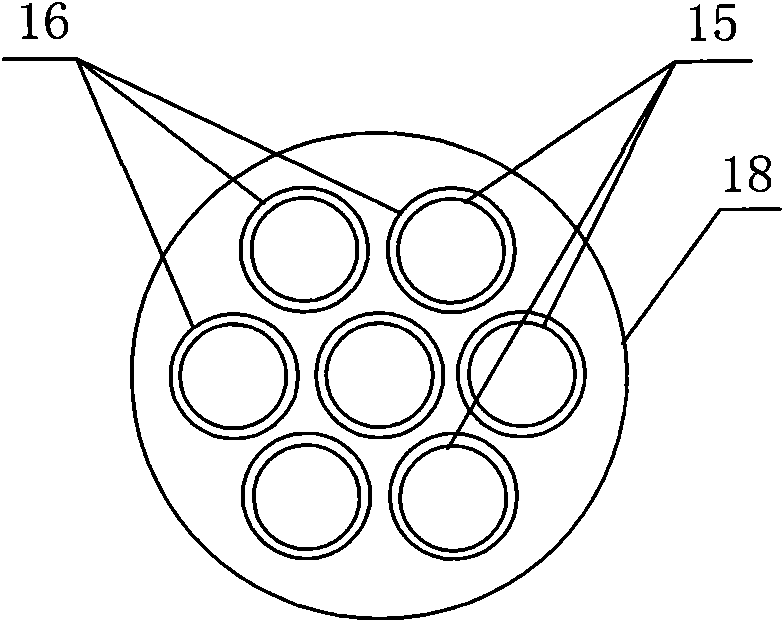

[0027] according to figure 1 , figure 2 with image 3 Shown, a kind of rapid heating distillation device in the process of refining titanium tetrachloride, comprises the distillation still connected successively by pipeline, distillation tower, cooler, breathing tank 10, ground tank 12 and finished product storage tank 11, still comprises : heavy tower still 1, light tower still 4 and alum removal tower still 7, distillation tower comprises: heavy fraction tower 2, light fraction tower 5 and alum removal fraction tower 8, cooler comprises: heavy tower cooler 3, Light tower cooler 6 and alum removal tower cooler 9; heavy tower still 1, heavy fraction towe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com