A gas distribution device and a gas water heater using the device

A gas water heater and distribution device technology, which is applied in the directions of gas fuel burners, gaseous fuel supply/distribution, burners, etc., can solve the difficulty of meeting regional differences, seasonal differences, individual differences among people, and uneven combustion of heat exchangers on one side. , piston or sealing ring is easy to wear, etc., to achieve the effect of convenient, quick and flexible adjustment, uniform and stable combustion flame, and improved work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

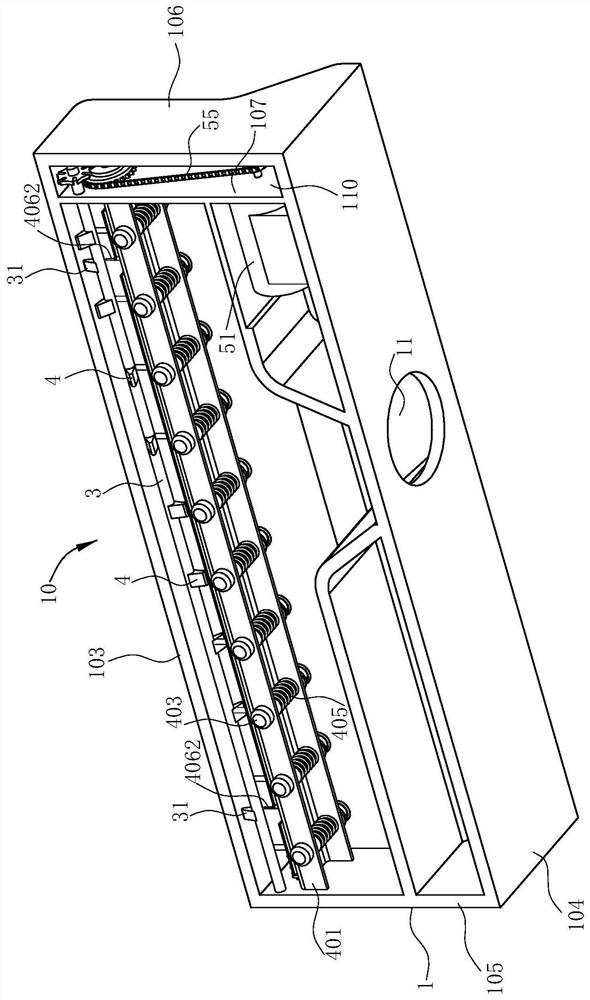

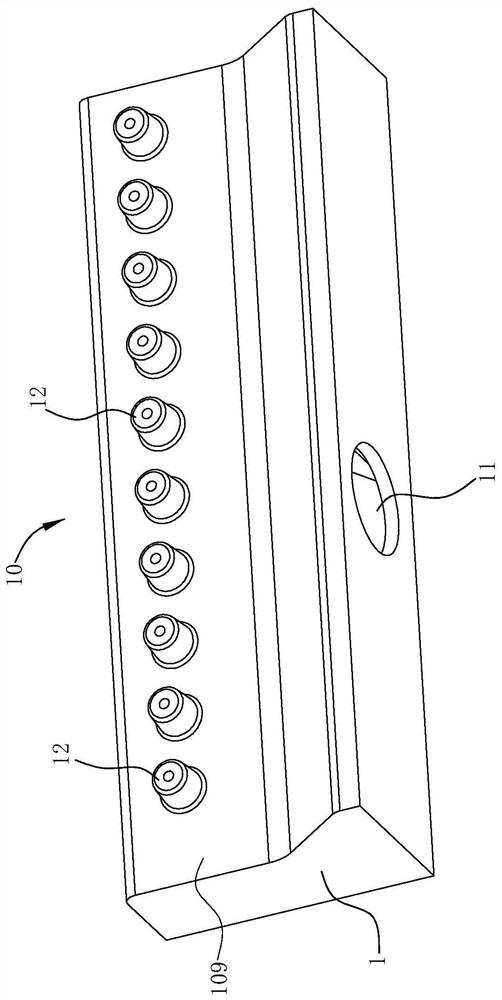

[0092] like Figure 15 As shown, the gas distribution device of this preferred embodiment is used in a gas water heater, and of course it can also be used in a gas wall-hung boiler. The gas water heater includes a burner 101, a gas distribution device 10, and a gas valve group 102 for controlling the gas intake.

[0093] like Figure 1-14 As shown, the gas distribution device 10 includes a housing 1, a nozzle 12 and a blocking member 2, a rotating shaft 3, a reset member, a driving mechanism, a connecting assembly and a power mechanism 5 arranged in the housing 1, the rotating shaft 3, the blocking member 2 Together with the power mechanism 5, it constitutes a blocking mechanism for blocking the nozzle 12. Housing 1 comprises top plate 103, bottom plate 104, left side plate 105, right side plate 106, connecting plate 107, front side plate 108 and rear side plate 109, top plate 103, bottom plate 104, left side plate 105, right side plate 106 and The rear side plate 109 is int...

Embodiment 2

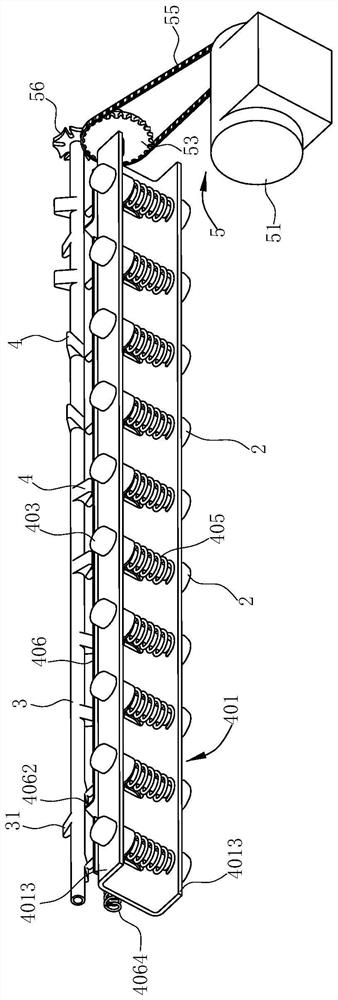

[0112] like Figures 17-28 As shown, the difference between Embodiment 2 and Embodiment 1 lies in that the power mechanism 5a, reset member, driving mechanism and connecting assembly of this embodiment are different.

[0113] First, the power mechanism 5a of this embodiment includes a motor 51a and a transmission mechanism. The motor 51a is a servo motor. The transmission mechanism includes a primary gear 52a connected to the output end of the motor 51a and a final gear 53a capable of transmitting power to the rotating shaft 3a. , the final gear 53a is arranged on the rotating shaft 3a, and the transmission between the primary gear 52a and the final gear 53a is through a chain 55a.

[0114] The driving structure and connecting components of the present embodiment are as follows: the housing 1a is provided with connecting frames 64 having the same number as the connecting components. 64 is provided with bayonet socket 641.

[0115] like Figures 19-21, 25-28, each of the con...

Embodiment 3

[0124] like Figures 29 to 34 As shown, the difference between Embodiment 3 and Embodiment 1 lies in that the power mechanism 5b, the driving mechanism and the connecting components of this embodiment are different.

[0125] In this embodiment, the power mechanism 5b includes a motor 51b and a transmission mechanism. The motor 51b is arranged on the bottom plate 104 and its power output end passes through the connecting plate 107 to the installation cavity 110. The transmission mechanism is located in the installation cavity 110 and includes a The output end of 51b drives the connected primary gear 52b and the final gear 53b that can transmit power to the rotating shaft 3b. The final gear 53b is arranged on the rotating shaft 3b. The transmission between the primary gear 52b and the final gear 53b is through the intermediate gear 54b.

[0126] In this embodiment, the driving mechanism is a driving block group, and the connecting component is a seesaw 408, specifically as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com