Ethylene glycol regeneration and recovery system in deep sea natural gas extraction process and ethylene glycol recovery method

A technology for developing processes and recovery systems, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve problems such as equipment scaling and corrosion, processes that cannot work properly, and lack, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

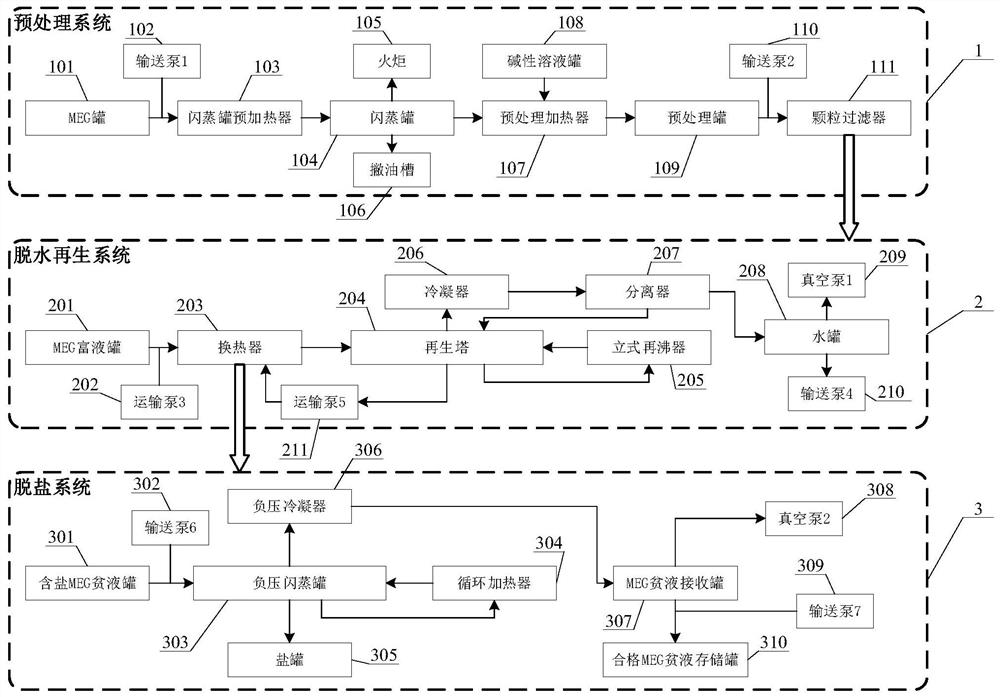

[0041] Such as figure 1 As shown, the ethylene glycol regeneration and recovery system in the deep-sea natural gas development process includes a pretreatment device responsible for removing light hydrocarbons and divalent salt ions in the ethylene glycol-rich liquid. Reclaimed water dehydration regeneration device 2 and desalination device 3 responsible for removing monovalent salt in the salt-containing ethylene glycol barren solution,

[0042] The pretreatment device 1 comprises the MEG tank 101 that stores the rich ethylene glycol solution from the upstream pipeline or facility, and the MEG tank 101 is connected with the flash tank preheater 103 through the first transfer pump 102 and the pipeline, and the flash tank preheater 103 is directly connected to the flash tank 104 through pipelines, and the flash tank 104 is provided with a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com