Rose essential oil and rose pure dew extraction equipment

A technology of rose hydrosol and extraction equipment, which is applied in the direction of essential oil/fragrance, fat production, etc. It can solve the problems of clogging steam pipes, low product quality, and affecting product quality, so as to improve distillation efficiency, high production efficiency, and effective Good for drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

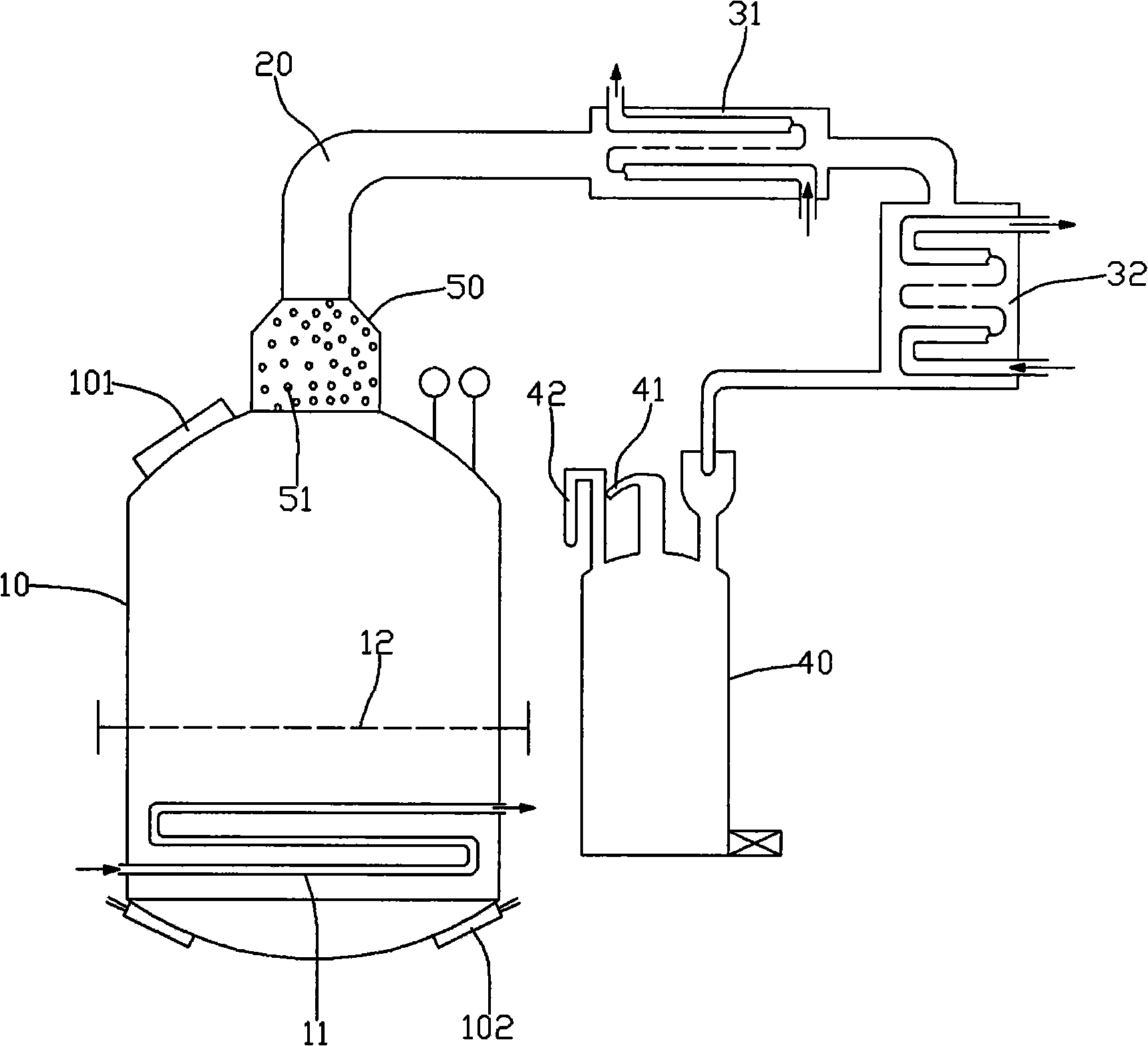

[0014] See attached figure 1 Shown: rose essential oil and rose pure dew extracting equipment of the present invention mainly include distillation kettle 10, steam pipeline 20, primary condenser 31 and secondary condenser 32, oil-water separator 40, and the lower end of distillation kettle 10 interior is provided with Open steam heating coil 11, the total surface area of the steam heating coil is 6M 2 The top of the steam heating coil 11 is provided with a horizontal plate sieve 12 that can be freely opened; the top of the still 10 is provided with an adsorption device 50 communicated with its inner cavity, and the adsorption device 50 is filled with an active ceramic ring 51 as an adsorbent, absorbing The outlet of the device 50 is connected with the oil-water separator 40 via the steam pipe 20 , the primary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total surface area | aaaaa | aaaaa |

| total surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com