Wine distillation equipment with filtration system

A filter system and distillation device technology, which is applied in the field of wine distillation devices, can solve the problems of affecting distillation efficiency, wasting energy, and inability to completely remove alcohol, so as to achieve the effect of improving distillation efficiency and saving energy

Inactive Publication Date: 2008-05-07

周清水

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention provides a wine distillation device with a filter system, the main purpose of which is to overcome the disadvantages of the existing wine distillation device without a filter system or with a relatively simple filter system that cannot remove or completely remove harmful substances in the liquor

[0005] Another object of the present invention is to provide a wine distillation device with a filter system to overcome the disadvantages of the existing wine distillation device that the heating tank is relatively simple, which affects the distillation efficiency and wastes energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 2

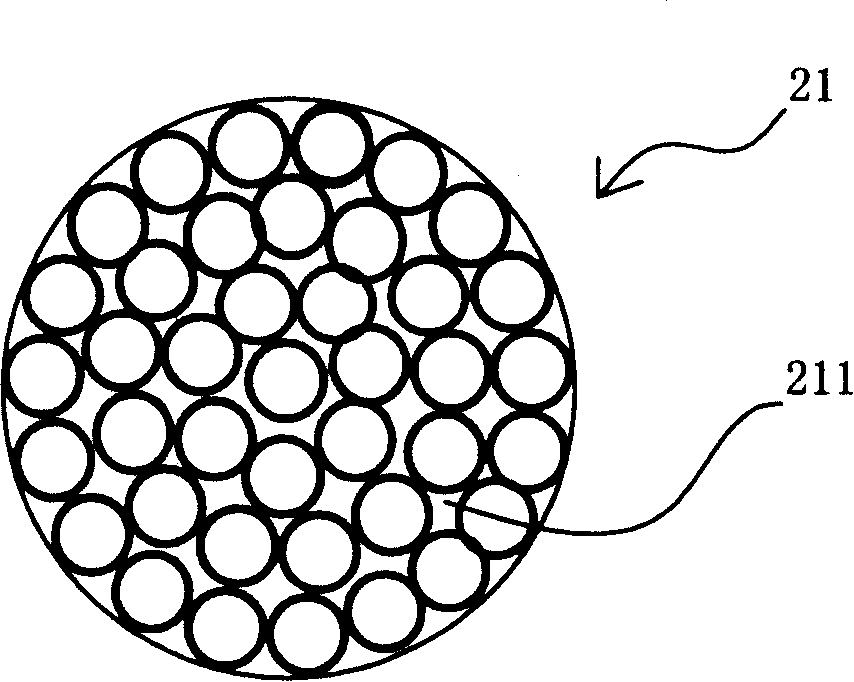

[0025] Specific embodiment two of the present invention, refer to Figure 5 , which is similar in principle and structure to Embodiment 1, except that the cross-section of the tubular diatomaceous earth ceramic membrane filter element 211 is a regular hexagonal structure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

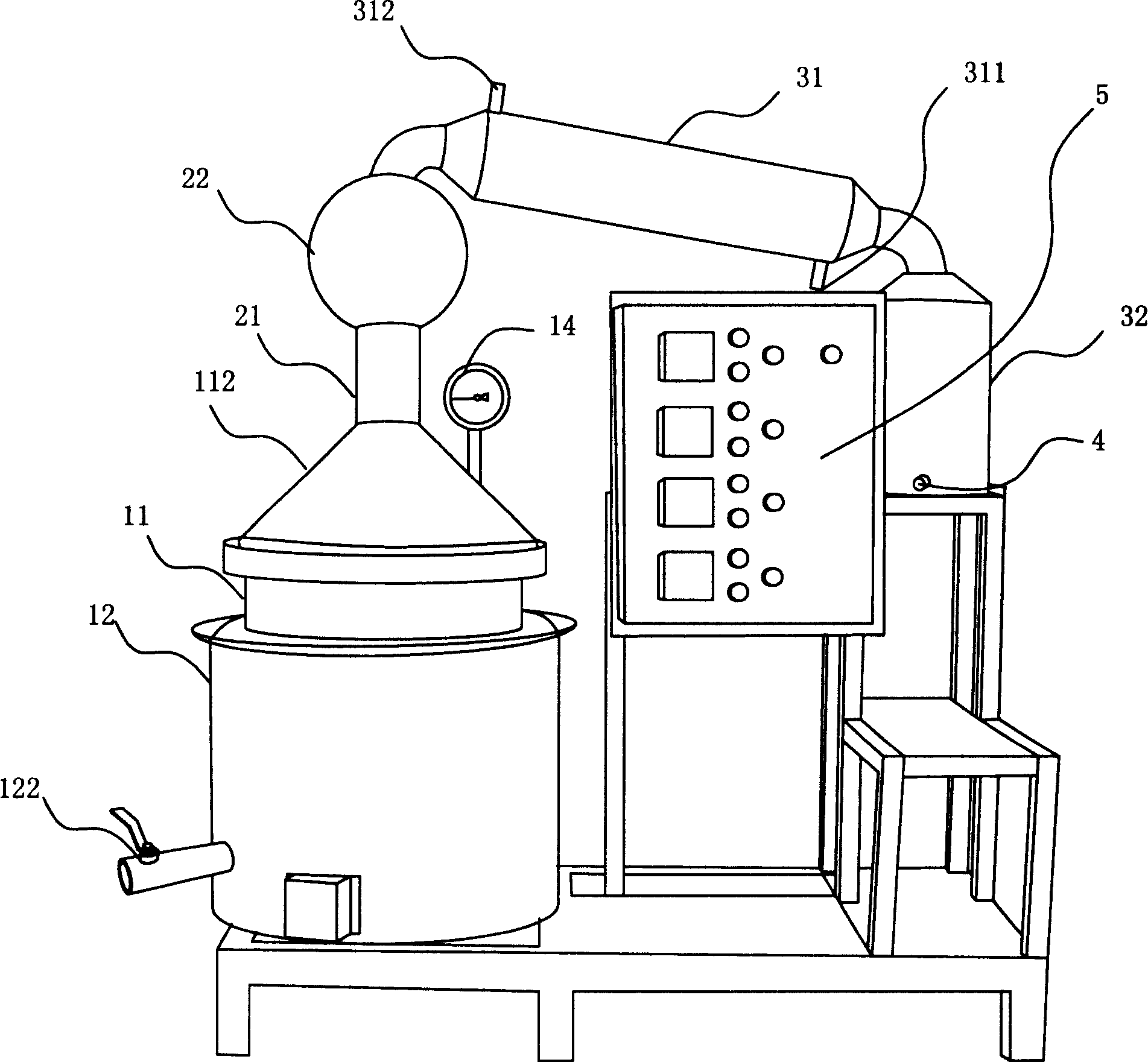

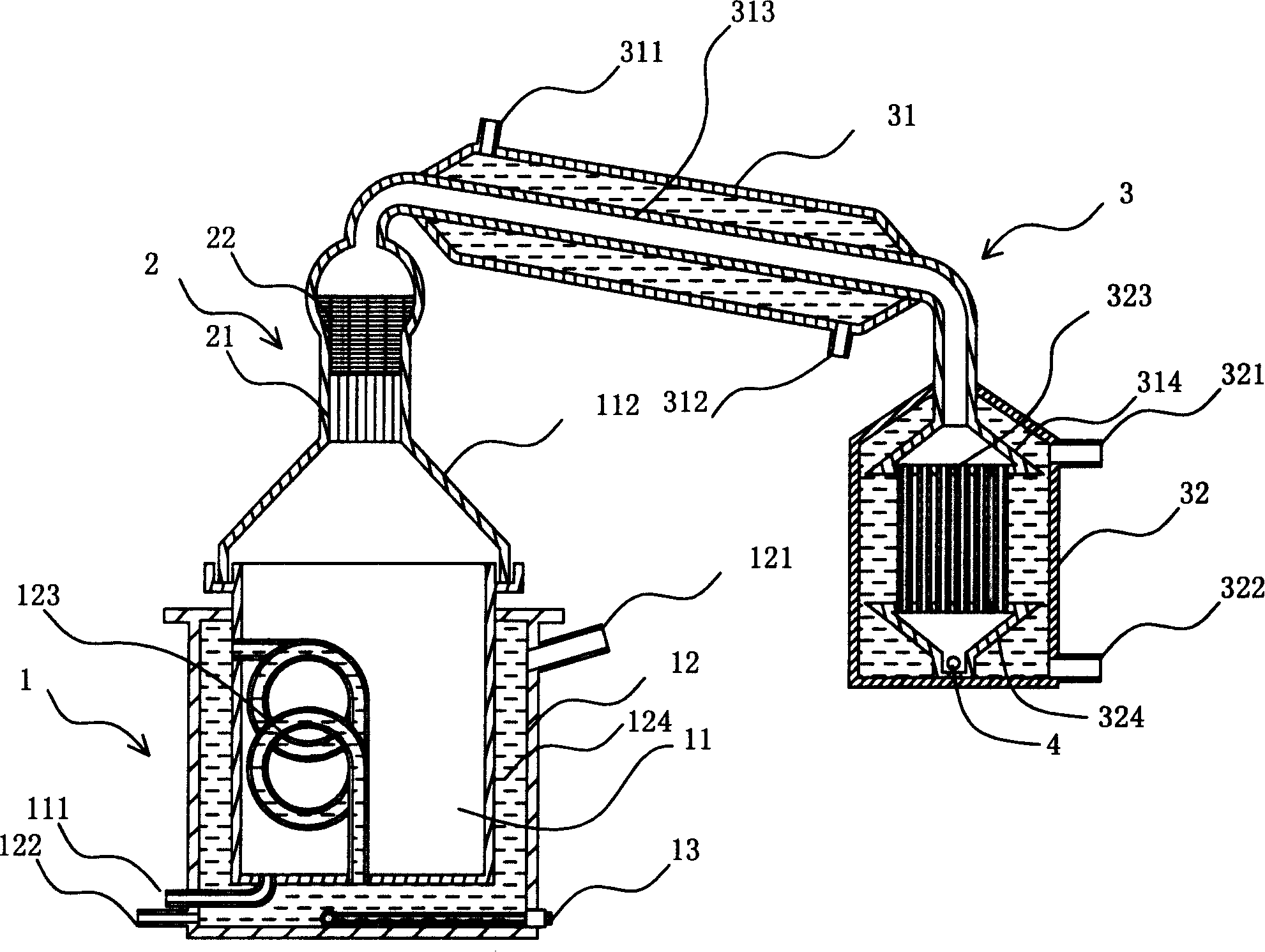

The invention relates to an alcoholic drink distillation apparatus with a filter system, which comprises a distillation system, a filter system and a condensing and cooling system connected through pipelines in sequence. The distillation system comprises a liquid heated kettle and a distillation kettle, the liquid heated kettle comprises a cavity encircling the outside of the distillation and used for holding the heated liquid, and the distillation kettle is provided inside with a spiral pipe with both ends communicated with the cavity of the liquid heated kettle; the filter system comprises a diatomite ceramic filter layer and a brass wires filter layer which are arranged along the vapor stream in sequence; the condensing and cooling system comprises a condensing pipe and a cooling tank filled with cooling water. The invention has the advantages of effectively removing the harmful substance such as pathogenic bacteria, impurity particles, remnants chlorin, heavy metal impurity and organic gas impurity, since the bi-layer filtration system of ceramic filter layer and brass wires filter layer is adopted, simultaneously improving the distillation efficiency and saving the energy due to a spiral pipe which is arranged inside the distillation kettle.

Description

technical field [0001] The invention relates to a wine distillation device, in particular to a wine distillation device with a filtering system. Background technique [0002] Distillation is an essential part of the winemaking process. The traditional wine distillation device is generally composed of a distillation system and a condensation cooling system. The disadvantage of this distillation device is that during the distillation process, some organic impurities and some impurity particles evaporate together with the wine vapor and enter the condensation system. The cooling system, which enters the wine collection tank, greatly affects the quality of the wine. To remove the organic impurities and impurity particles, it is necessary to add a new filter device, which not only wastes resources, but also complicates the operation, which affects production efficiency. At present, some wine distillation devices use a ceramic filter layer at the wine steam outlet to enhance the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12G3/12C12H6/02

Inventor 周清水

Owner 周清水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com